Method for improving biomass and oil fat yield of microorganisms

A biomass and microbial technology, applied in the field of microalgae and yeast biological fermentation and cultivation, to achieve the effects of reducing energy consumption and production costs, alleviating unfavorable factors, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

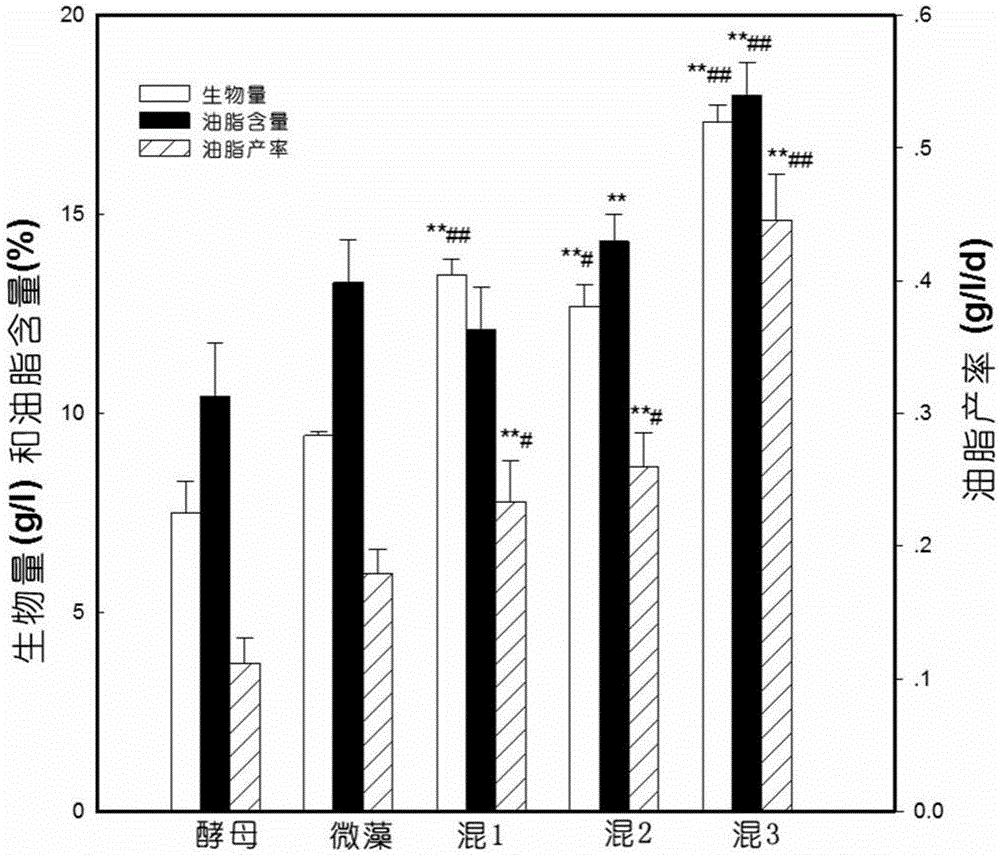

[0031] A method for improving microbial biomass and oil production, comprising the steps of:

[0032] 1) Activation culture: respectively inoculate the cells of Chlorella and Rhodotorula viscosus in the medium for activation and culture to the logarithmic growth phase and serve as the seed solution;

[0033] 2) Chlorella and yeast were inoculated in different ratios (1:1-3:1) into Basal medium (yeast extract was used as N source to replace NaNO 3 ) in a shaker flask, placed in a light incubator at 28°C, 150 rpm, with a light intensity of 100 μmol m -2 the s -1 Cultivate for 7 days; wherein, the composition of Basal medium is:

[0034] 1.25g / L sodium nitrate, 1.25g / L methyl dihydrogen phosphate, 1g / L magnesium sulfate heptahydrate, 0.5g / L EDTA, 0.111g / L calcium chloride, 0.0498g / L iron sulfate heptahydrate, 0.004g / L cobalt nitrate hexahydrate, 0.0119g / L sodium molybdate dihydrate, 0.057g / L boric acid, 0.04g / L zinc sulfate heptahydrate, 7.1mg / L manganese chloride monohydrate...

Embodiment 2

[0051] A method for improving microbial biomass and oil production, comprising the steps of:

[0052] 1) Activation culture: respectively inoculate the cells of Chlorella and Candida tropicalis in the medium for activation and culture to the logarithmic growth phase and serve as the seed solution;

[0053] 2) Chlorella and Candida tropicalis were inoculated in different ratios (1:1-3:1) into Basal medium (yeast extract was used as N source to replace NaNO 3 ) in a shaker flask, placed in a light incubator at 28°C, 150 rpm, with a light intensity of 100 μmol m - 2 the s -1 Cultivate for 7 days; wherein, the composition of Basal medium is:

[0054] 1.25g / L sodium nitrate, 1.25g / L methyl dihydrogen phosphate, 1g / L magnesium sulfate heptahydrate, 0.5g / L EDTA, 0.111g / L calcium chloride, 0.0498g / L iron sulfate heptahydrate, 0.004g / L cobalt nitrate hexahydrate, 0.0119g / L sodium molybdate dihydrate, 0.057g / L boric acid, 0.04g / L zinc sulfate heptahydrate, 7.1mg / L manganese chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com