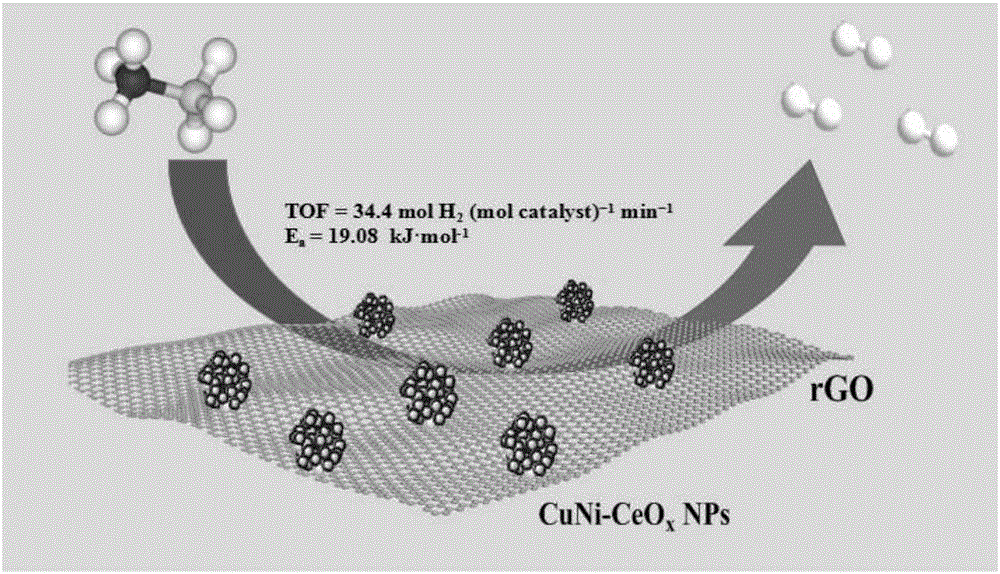

Graphene-loaded copper and nickel/cerium oxide nanocomposite material, preparation method and ammonia borane catalytic decomposition method

A nanocomposite material and catalytic decomposition technology are applied in the catalytic decomposition of ammonia borane, graphene-supported copper-nickel/cerium oxide nanocomposite materials, and the field of preparation, which can solve the problems of limited storage of precious metals, high price, and influence on catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a graphene-loaded copper-nickel / cerium oxide nanocomposite, characterized in that it comprises:

[0030] 1) graphene oxide and water are mixed to make graphene oxide aqueous solution;

[0031] 2) Disperse the nickel source, copper source and cerium source in the graphene oxide aqueous solution, and then add a reducing agent to the system under nitrogen atmosphere for reduction reaction to prepare graphene-supported copper-nickel / cerium oxide nanocomposites.

[0032] In step 1) of the above-mentioned preparation method, the consumption of each material can be selected in a wide range, but graphene oxide is better dispersed and then the graphene-loaded copper-nickel / cerium oxide nanocomposite material made has better Excellent catalytic performance, preferably, in step 1), relative to 10 mg of graphene oxide, the amount of water used is 5-15 mL.

[0033] In step 1) of the above-mentioned preparation method, the mixing method ...

Embodiment 1

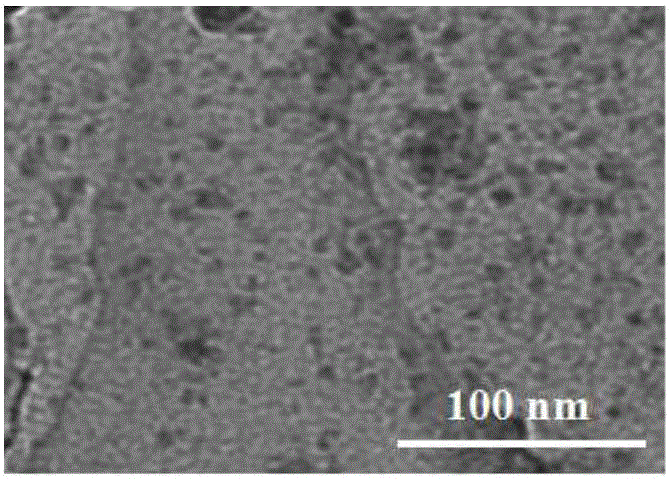

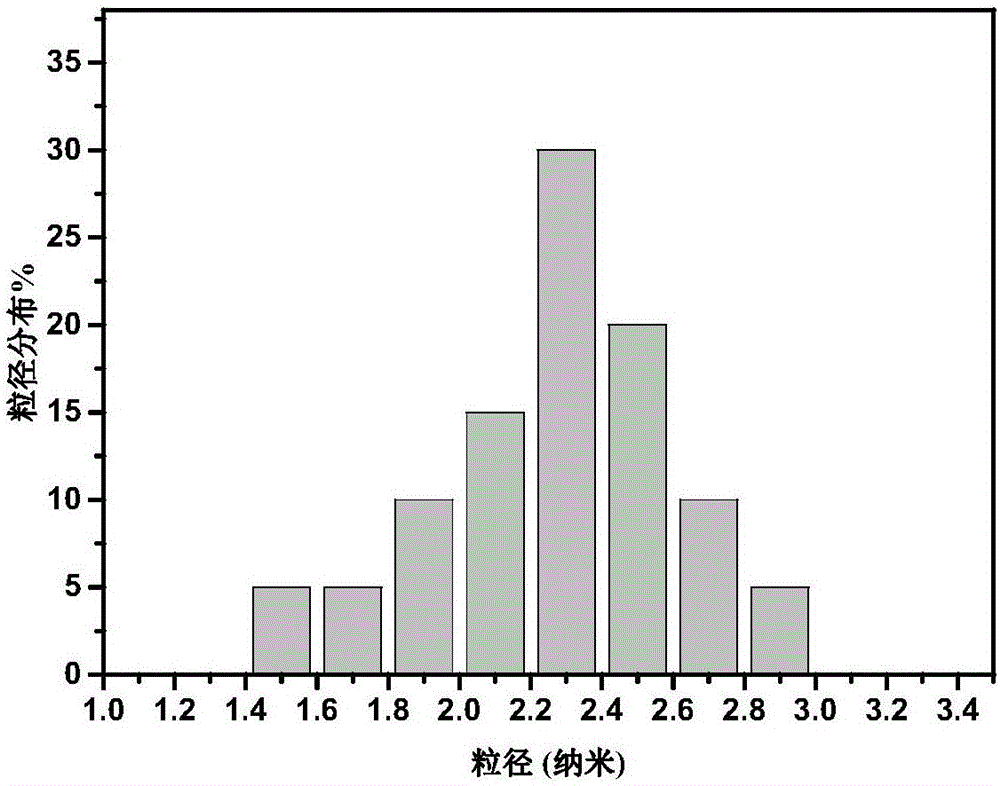

[0048] Dissolve 10 mg of graphene oxide in 5 mL of ultrapure water, and ultrasonicate for 10 min; then add 4.8 mg of nickel chloride hexahydrate, 13.6 mg of copper chloride and 7.1 mg of cerium nitrate hexahydrate into the system, and stir for 1 h under magnetic stirring to make The solution was uniformly dispersed; then, 30 mg of sodium borohydride was quickly added to the mixed solution under a nitrogen atmosphere, and the stirring was continued at 25 °C for 6 h; finally, the nanocomposite Cu 0.8 Ni 0.2 -CeO x / rGO (the molar ratio of Cu and Ni is 0.8:0.2, and Ce / (Cu+Ni+Ce) is 13.9 mol%).

Embodiment 2

[0050] Carry out Cu according to the method for embodiment 1 0.9 Ni 0.1 -CeO x / rGO (the molar ratio of Cu and Ni is 0.9:0.1, Ce / (Cu+Ni+Ce) is 13.9mol%), the difference is: the consumption of nickel chloride hexahydrate is 2.4mg, and the consumption of copper chloride is 15.3 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com