Method for preparing monodispersing decahedral gold nano-particles in ethylene glycol

A technology for the production of ethylene glycol and nanoparticles, which is applied in chemical instruments and methods, crystal growth, metal processing equipment, etc. It can solve the problems of unavoidable oxidation and etching, and achieve rich raw materials, good absorption performance, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

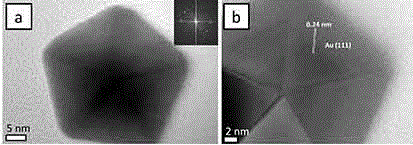

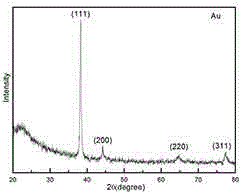

[0027] Preparation of 30 nm Monodisperse Gold Decahedral Nanoparticles

[0028]First add polydiallyldimethylammonium chloride (PDDA, Mw=100000-200000, 20 wt%) aqueous solution to the ethylene glycol solution, stir well to obtain a mixed solution; then add in sequence under magnetic stirring conditions Chlorauric acid (HAuCl4), and a small amount of silver nitrate (AgNO3), iron trichloride (FeCl3), sodium bicarbonate (NaHCO3) aqueous solution to obtain a reaction precursor solution, in which polydiallyl dimethyl ammonium chloride (PDDA), chloroauric acid (HAuCl4), silver nitrate (AgNO3), ferric chloride (FeCl3), sodium bicarbonate (NaHCO3) in the precursor concentration are 0.025 mol / L, 0.00025 mol / L, 0.0016 mol / L, 0.00000025 mol / L, 0.00025 mol / L; then, the reaction precursor solution was placed at 215°C for 1 hour to obtain a red colloid solution, which was naturally cooled to room temperature, and then used a high-speed centrifuge at a speed of 14500 rpm After centrifuging f...

Embodiment 2

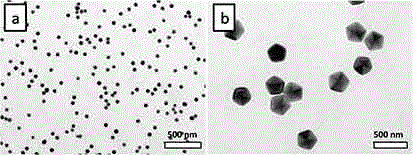

[0030] Preparation of 40 nm Monodisperse Gold Decahedral Nanoparticles

[0031] First add the ethylene glycol (EG) solution with a concentration of 0.025 mol / L into the reaction vessel; then add ascorbic acid (AA) and chloroauric acid (HAuCl4) solutions to the reaction vessel in sequence and shake well; The gold decahedral nanoparticles synthesized by the preparation method in Example 1 were added to the mixed solution to obtain a reaction precursor solution, in which polydiallyldimethylammonium chloride (PDDA), ascorbic acid (AA), chloroauric acid (HAuCl4), the concentrations of gold decahedral nanoparticle seeds were 0.025 mol / L, 0.005 mol / L, 0.00005 mol / L, and 0.000125 mol / L; finally, the reaction precursor solution was placed at room temperature and reacted for 30 minutes, Obtain purple-red colloidal solution, use high-speed centrifuge to centrifuge under the condition of rotating speed 12000 rpm for 20 minutes, remove the colorless solution in the centrifuge tube to obtai...

Embodiment 3

[0033] Preparation of 50 nm Monodisperse Gold Decahedral Nanoparticles

[0034] First add the ethylene glycol (EG) solution with a concentration of 0.025 mol / L into the reaction vessel; then add ascorbic acid (AA) and chloroauric acid (HAuCl4) solutions to the reaction vessel in sequence and shake well; The gold decahedral nanoparticles synthesized by the preparation method in Example 1 were added to the mixed solution to obtain a reaction precursor solution, in which polydiallyldimethylammonium chloride (PDDA), ascorbic acid (AA), chloroauric acid (HAuCl4), the concentrations of gold decahedral nanoparticle seeds were 0.025 mol / L, 0.005 mol / L, 0.0001 mol / L, and 0.000125 mol / L; finally, the reaction precursor solution was placed at room temperature and reacted for 30 minutes, Obtain a blue colloidal solution, centrifuge at a speed of 11,000 rpm for 10 minutes with a high-speed centrifuge, remove the colorless solution in the centrifuge tube to obtain a blue precipitate product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com