Method of treating stainless steel passivating cleaning wastewater by employing calcium carbide waste residue

A technology for cleaning waste water and calcium carbide waste residue, which is applied in the fields of metallurgical waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. It can solve the problems of increasing sludge deposition, slow reaction rate and slow neutralization reaction speed , to achieve the effects of significant environmental and economic benefits, efficient production and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

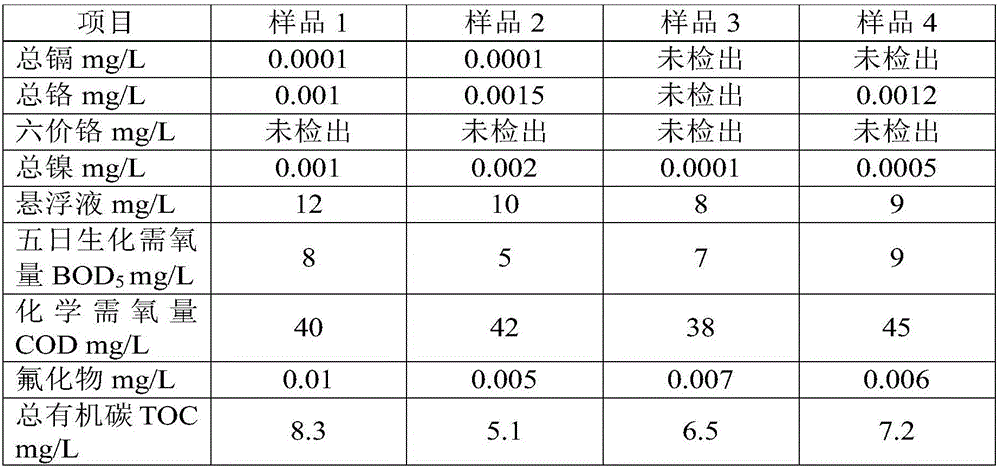

Embodiment 1

[0035] A method for treating stainless steel passivation cleaning wastewater by utilizing calcium carbide waste slag, comprising the following steps:

[0036] Step S1, the stainless steel passivation cleaning wastewater is imported into the wastewater regulating tank, and then transferred to the neutralization tank, and liquid alkali is added to the neutralization tank through a metering pump, so that the pH value of the stainless steel passivation cleaning wastewater is adjusted to 8.5, and the alkali Adjusted stainless steel passivation cleaning wastewater;

[0037] Step S2, the alkali-adjusted stainless steel passivation cleaning wastewater obtained in step S1 flows into the clarification tank, and a cationic polyacrylamide with a quality of 0.003‰ of the alkali-adjusted stainless steel passivation cleaning wastewater is added through a metering pump to make the alkali-adjusted stainless steel passivation cleaning wastewater Fe in stainless steel passivation cleaning wastew...

Embodiment 2

[0042] A method for treating stainless steel passivation cleaning wastewater by utilizing calcium carbide waste slag, comprising the following steps:

[0043] Step S1, the stainless steel passivation cleaning wastewater is imported into the wastewater regulating tank, and then transferred to the neutralization tank, and liquid alkali is added to the neutralization tank through a metering pump, so that the pH value of the stainless steel passivation cleaning wastewater is adjusted to 9.5, and the alkali Adjusted stainless steel passivation cleaning wastewater;

[0044] In step S2, the alkali-adjusted stainless steel passivation cleaning wastewater obtained in step S1 flows into the clarification tank, and a cationic polyacrylamide with a quality of 0.005‰ of the alkali-adjusted stainless steel passivation cleaning wastewater is added through a metering pump to make the alkali-adjusted stainless steel passivation cleaning wastewater Fe in stainless steel passivation cleaning was...

Embodiment 3

[0049] A method for treating stainless steel passivation cleaning wastewater by utilizing calcium carbide waste slag, comprising the following steps:

[0050] Step S1, the stainless steel passivation cleaning wastewater is imported into the wastewater regulating tank, and then transferred to the neutralization tank, and liquid alkali is added to the neutralization tank through a metering pump to adjust the pH value of the stainless steel passivation cleaning wastewater to 9 to obtain alkali Adjusted stainless steel passivation cleaning wastewater;

[0051] Step S2, the alkali-adjusted stainless steel passivation cleaning wastewater obtained in step S1 flows into the clarification tank, and a cationic polyacrylamide with a quality of 0.004‰ of the alkali-adjusted stainless steel passivation cleaning wastewater is added through a metering pump to make the alkali-adjusted stainless steel passivation cleaning wastewater Fe in stainless steel passivation cleaning wastewater 3+ 、Cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com