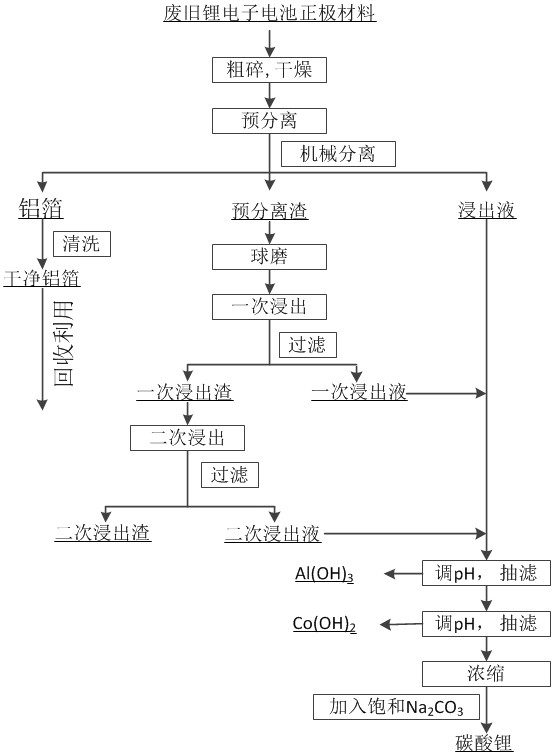

A kind of mixed acid leaching and recycling method of waste lithium ion battery cathode material

A lithium-ion battery and leaching technology, which is applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as comprehensive recovery of difficult and valuable metals, high requirements for leachate, and complicated recycling processes, and achieve low raw material thresholds, The effect of high leaching efficiency and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Break 200g of lithium battery positive electrode waste into pieces of 10mm×10mm, the drying temperature is 95°C, and the drying time is 3h;

[0068] Table 1 Composition of metal elements in cathode materials of waste lithium-ion batteries

[0069] Metal co Ni Fe mn Al Li Content (wt.%) 15.33 11.27 8.9 7.4 3.05 2.96

[0070] Preleaching the positive electrode waste with nitric acid, sulfuric acid (5vol.%) and citric acid (35vol.%) mixed acid containing hydrogen peroxide and sodium sulfite as reducing agent, and filtering to obtain aluminum foil, pre-separation slag and preleaching solution; the acid The concentration is 3mol / L, the mass percentage of the reducing agent is 5%, the leaching S / L is 100g / L, the leaching temperature is 60°C, the leaching time is 120min, and the stirring speed is 150rpm; the aluminum foil, the pre-separated slag and the pre-separated slag are obtained. Leachate. The obtained aluminum foil is cleaned to obt...

Embodiment 2

[0075] Break 200g of lithium battery positive electrode waste into pieces of 15mm×15mm, the drying treatment temperature is 105°C, and the drying treatment time is 4h;

[0076] Table 2 Composition of metal elements in cathode materials of waste lithium-ion batteries

[0077] Metal co Ni Fe mn Al Li Content (wt.%) 10.31 8.71 7.45 7.01 4.35 3.46

[0078] Use trichloroacetic acid and sulfuric acid (25vol.%) mixed acid containing hydrogen peroxide and sodium sulfite as reducing agent to perform pre-leaching on positive electrode waste, and filter to obtain aluminum foil, pre-separated slag and pre-leaching solution; the acid concentration is 2.5mol / L , the mass percentage of the reducing agent is 3%, the leaching S / L is 80g / L, the leaching temperature is 55°C, the leaching time is 80min, and the stirring speed is 200rpm; aluminum foil, pre-separated slag and preleaching solution are obtained. The obtained aluminum foil is cleaned to obtain a cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com