Simple preparation method of carbon self doped carbon nitride nano film electrode

A nano-film and thin-film electrode technology, applied in the field of photoelectrochemical hydrogen production semiconductor electrodes, can solve the problems of limiting the application of carbon nitride materials, lack of methods, etc., to solve the problems of current transfer, simple and easy preparation methods, and improved activity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of self-sensitizing carbon nitride film precursor solution

[0035]Add 166mg (0.9mmol) of cyanuric chloride and 5.8mg (0.045mmol) of cyanuric acid into 15mL of acetonitrile, stir it magnetically to make it fully dissolve (300 rpm), and obtain a self-sensitized carbon nitride film The precursor solution, wherein the concentration of cyanuric chloride is 0.06mol / L, and the concentration of cyanuric acid is 0.003mol / L.

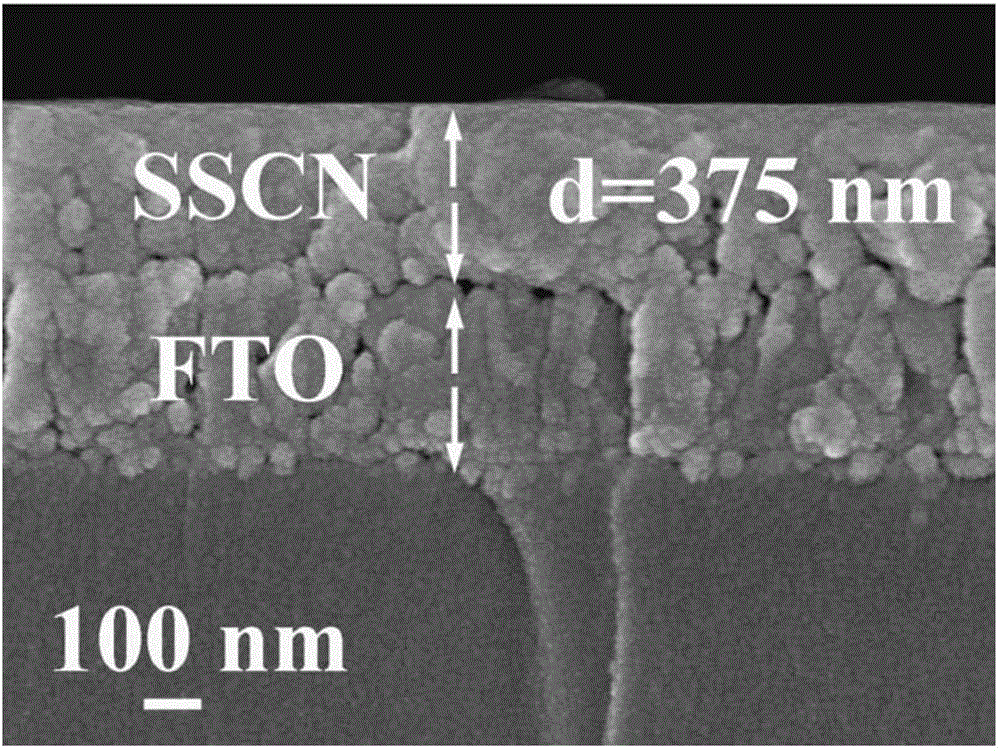

[0036] 2. Preparation of self-sensitizing carbon nitride thin film electrodes

[0037] After the FTO conductive glass (1.0cm×2.5cm) was ultrasonically washed with acetone, ethanol and distilled water, respectively, it was washed with N 2 Purge and dry, then put it into a mixture of ammonia water with a mass fraction of 25% to 28%, hydrogen peroxide with a mass fraction of 30%, and a water volume ratio of 1:1:5, soak at 60°C for 3 hours, and then Sonicated and washed with N 2 Purge and dry to obtain surface hydroxylated FTO conductive glas...

Embodiment 2

[0042] 1. Preparation of self-sensitizing carbon nitride film precursor solution

[0043] This step is the same as Step 1 of Example 1.

[0044] 2. Preparation of self-sensitizing carbon nitride thin film electrodes

[0045] After the FTO conductive glass (1.0cm×2.5cm) was ultrasonically washed with acetone, ethanol and distilled water, respectively, it was washed with N 2 Purge and dry, then use metal titanium as the target material, grow a layer of metal titanium film with a thickness of about 100nm on the FTO conductive glass by sputtering, and then calcinate the FTO conductive glass with metal titanium film at 500°C in the air atmosphere 2 hours, get TiO 2 / FTO substrate. Add 15 mL of the self-sensitizing carbon nitride thin film precursor solution into a polytetrafluoroethylene autoclave, and place two pieces of TiO 2 / FTO substrate is suspended in the precursor solution of self-sensitized carbon nitride film, then the autoclave is sealed and placed in an oven, the te...

Embodiment 3

[0050] 1. Preparation of self-sensitizing carbon nitride film precursor solution

[0051] This step is the same as Step 1 of Example 1.

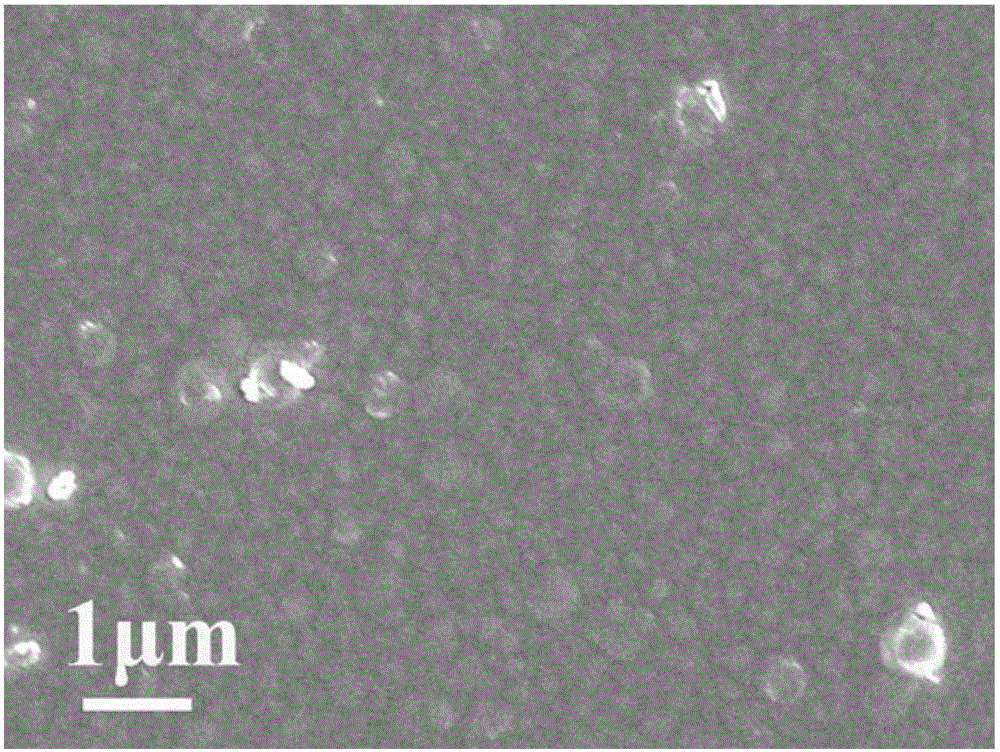

[0052] 2. Preparation of self-sensitizing carbon nitride thin film electrodes

[0053] This step is the same as Step 2 of Example 1.

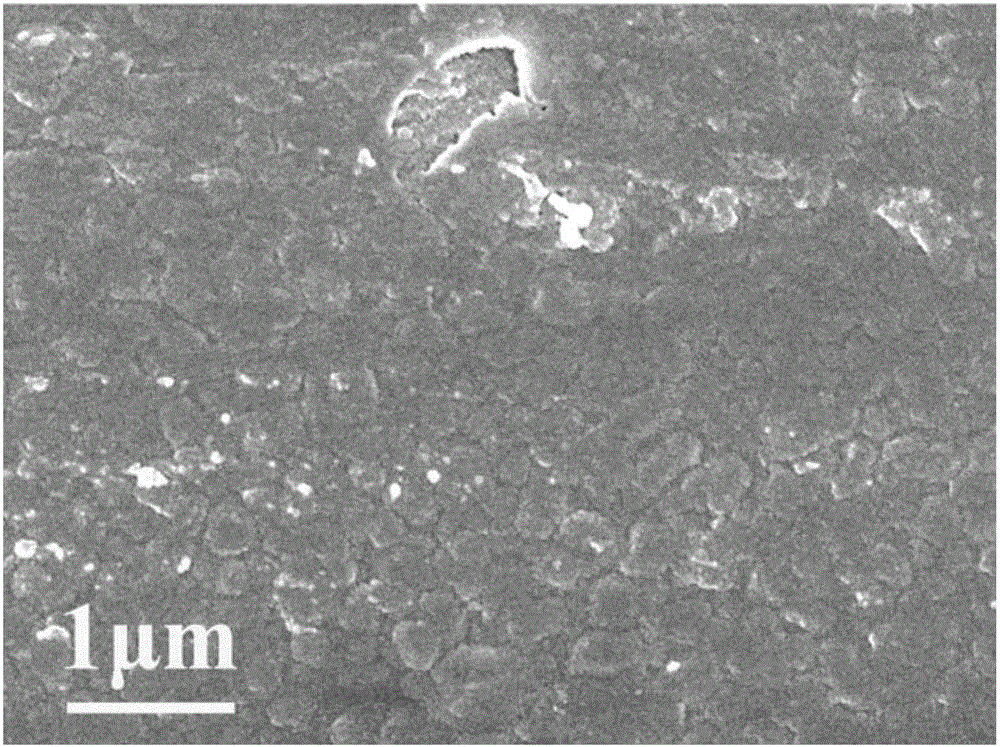

[0054] 3. Preparation of carbon self-doped carbon nitride nanofilm electrodes

[0055] In this step, the temperature is raised to 400°C at a heating rate of 5°C / min, and the constant temperature is calcined for 2 hours to grow a carbon self-doped carbon nitride film on the FTO conductive glass. The other steps are the same as step 3 of Example 1, and the carbon self-doped Doped carbon nitride nano film electrode, wherein the thickness of carbon self-doped carbon nitride nano film is 185nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com