One-pot preparation of sio 2 - Method for cellulose composite airgel material

A technology of composite aerogel and cellulose is applied in the field of preparing SiO2-cellulose composite aerogel materials by one-pot method. Effective, simple process, and the effect of inhibiting phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

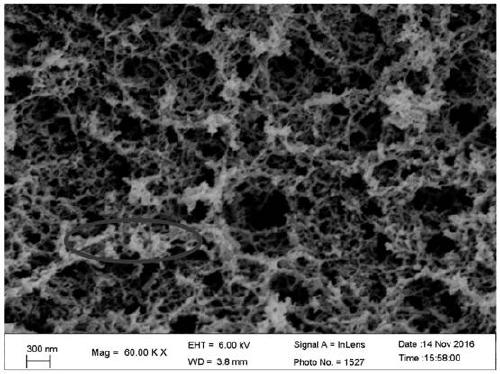

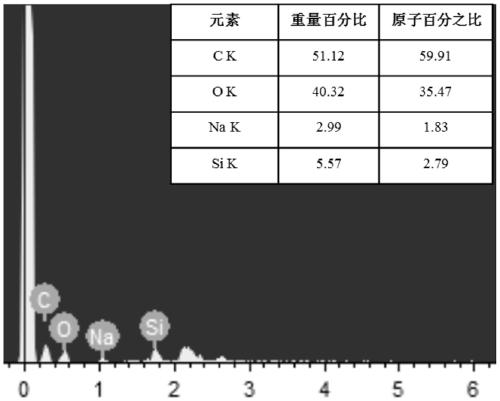

example 1

[0036] 1. Stir and disperse 2g of microcrystalline cellulose into alkali urea solution (4.0gLiOH / 10gUrea / 84gH 2 O), after dispersion, transfer to the refrigerator to pre-cool at -5°C, immediately use a motor to stir at 2000rpm for 4min to dissolve the cellulose to obtain a viscous solution, then immediately centrifuge at 8000rpm for 10min to remove air bubbles Obtain a clear and transparent cellulose solution, the solvent mass fraction is 2%; Weigh 16.3g of Na 2 SiO 3 9H2 O magnetically stirred and dissolved in 83.7g of distilled water to obtain a sodium silicate aqueous solution with a mass fraction of 7%. The cellulose solution and the sodium silicate solution were mechanically stirred and mixed at a volume ratio of 10:1, and then ultrasonically oscillated to remove air bubbles to form a uniform Mixed sodium silicate-cellulose mixed solution. Then pour the uniformly mixed sodium silicate-cellulose mixed solution into the mold and place it in a methanol coagulation bath for...

example 2

[0038] Stir and disperse 6g of cotton pulp cellulose into alkali urea solution (4gLiOH / 10gThourea / 80gH 2 O), after dispersion, transfer to the refrigerator to pre-cool at -20°C, immediately use a motor to stir at 2000rpm for 4min to dissolve the cellulose to obtain a viscous solution, then immediately centrifuge at 10000rpm for 5min to remove air bubbles Obtain clear and transparent cellulose solution, the solvent mass fraction is 6%; The Na of 1.74g is weighed 2 SiO 3 ·5H 2 Dissolve in 98.3g of distilled water with magnetic stirring to obtain a sodium silicate aqueous solution with a mass fraction of 1%. The cellulose solution and sodium silicate solution are mechanically stirred and mixed at a volume ratio of 1:1, and ultrasonic vibration is used to remove air bubbles to form a uniform mixture. sodium silicate-cellulose mixed solution. Then pour the uniformly mixed sodium silicate-cellulose mixed solution into the mold and place it in an ethanol coagulation bath for regen...

example 3

[0040] The linter cellulose of 3g is stirred and dispersed into alkali urea solution (wherein 4.6gNaOH / 15gUrea / 77.4gH 2 O), after dispersion, transfer to the refrigerator to pre-cool at -15°C, immediately use the motor to stir at 1000rpm for 12min to dissolve the cellulose to obtain a viscous solution, then immediately centrifuge at 8000rpm for 10min to remove air bubbles Obtain a clear and transparent cellulose solution with a solvent mass fraction of about 3%; weigh 3g of anhydrous Na 2 SiO 3 Dissolve in 97ml of distilled water with magnetic stirring to obtain a sodium silicate aqueous solution with a mass fraction of 3%. The cellulose solution and the sodium silicate solution are mechanically stirred and mixed at a volume ratio of 2:1, and ultrasonically oscillated to remove air bubbles to form Uniformly mixed sodium silicate-cellulose mixed solution. Then pour the uniformly mixed sodium silicate-cellulose mixed solution into the mold and place it in an acetone coagulatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com