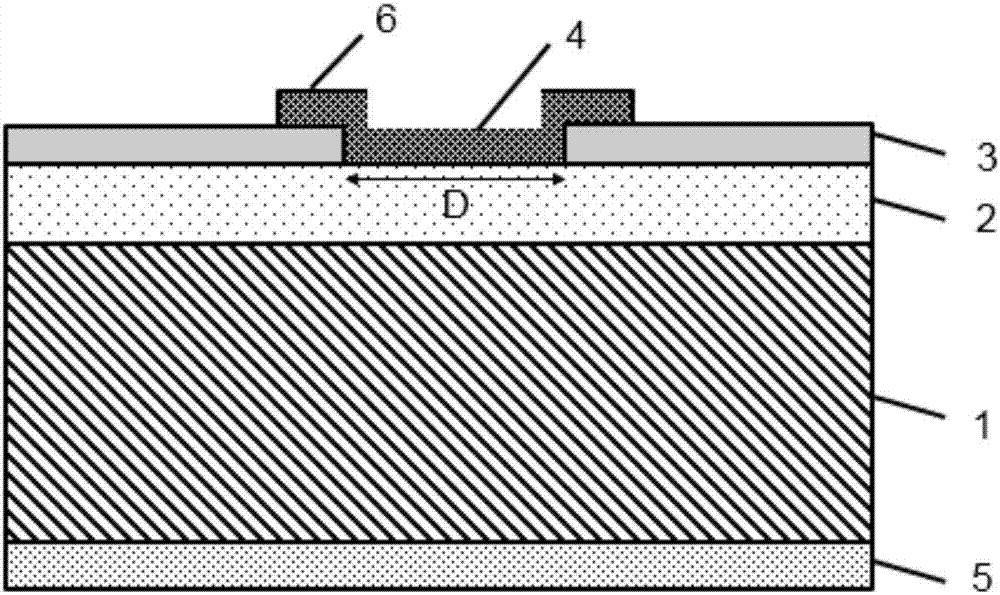

High-breakdown-voltage gallium-oxide Schottky diode and manufacturing method thereof

A Schottky diode, high breakdown voltage technology, used in circuits, electrical components, semiconductor/solid-state device manufacturing, etc. and other problems, to achieve the effect of enhanced depletion, good device performance, and improved breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

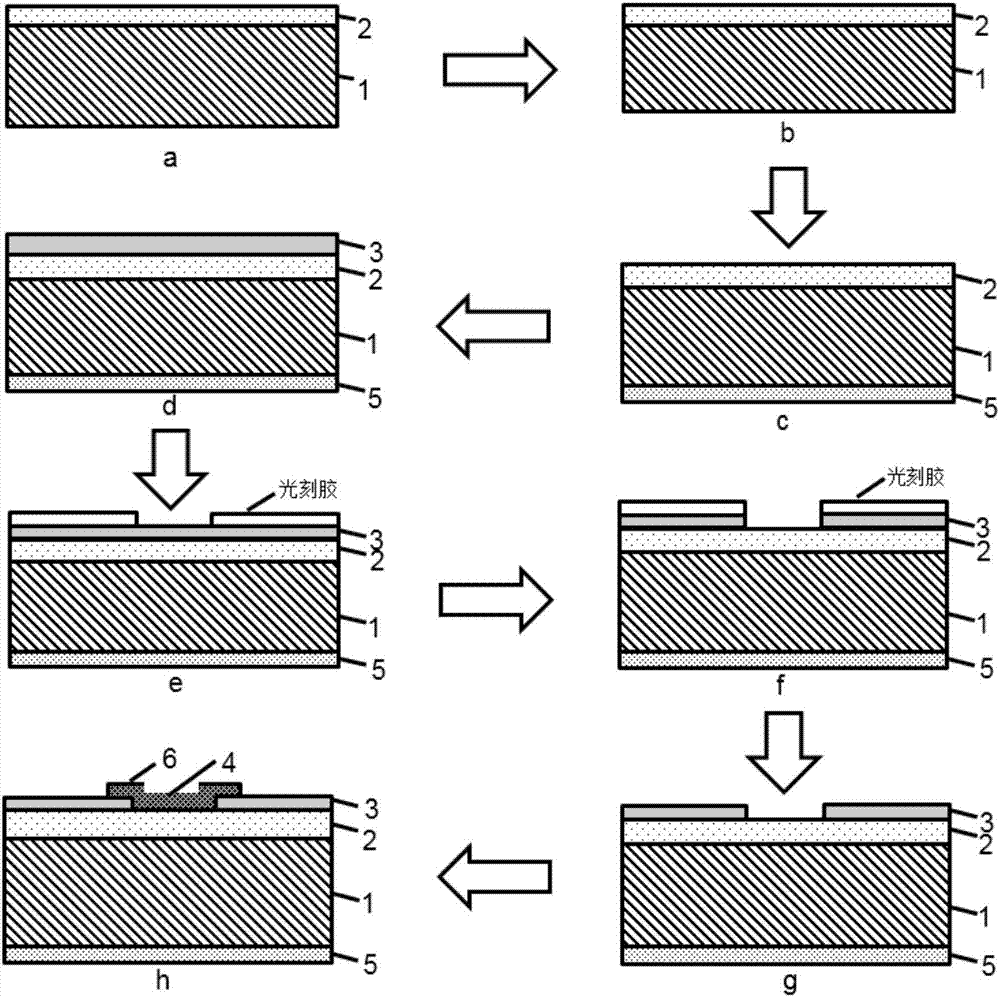

[0030] Example 1, fabricate a Schottky diode with a thickness of 300nm as the organic ferrodielectric and using vinylidene fluoride-trifluoroethylene copolymer P(VDF-TrFE) as the organic ferrodielectric.

[0031] Step 1, for the carrier concentration already at 10 18 cm -3 Epitaxially grown on the substrate with a carrier concentration of 10 16 cm -3 Ga 2 o 3 The epitaxial layer samples were cleaned as figure 2 a.

[0032] Ga 2 o 3 The samples were cleaned organically, that is, put them into an acetone solution for 5 minutes, then put them into an ethanol solution for 5 minutes; then wash them with deionized water; then put them into HF:H 2 Corrosion was carried out in the solution of O=1:1 for 50s; finally, it was washed with flowing deionized water and dried with high-purity nitrogen.

[0033] Step 2, etch, such as figure 2 b.

[0034] Put the cleaned sample face down into the ICP etching reaction chamber, and etch the lower surface of the substrate. The process...

Embodiment 2

[0048] Example 2, making a Schottky diode with a thickness of 400nm as the organic ferrodielectric, and Ag-P (VDF-TrFE) material doped with silver nanoparticles as the organic ferrodielectric.

[0049] Step 1, for the carrier concentration already at 10 19 cm -3 Epitaxially grown on the substrate with a carrier concentration of 10 15 cm -3 Ga 2 o 3 The epitaxial layer samples were cleaned as figure 2 a.

[0050] The specific implementation of this step is the same as step 1 of Embodiment 1.

[0051] Step two, etching.

[0052] Put the cleaned sample face down into the ICP etching reaction chamber, and etch the lower surface of the substrate. The process conditions are: the power of the upper electrode is 100W, the power of the lower electrode is 10W, the pressure of the reaction chamber is 25Pa, BCl 3 The flow rate of Ar gas is 10 sccm, the flow rate of Ar gas is 20 sccm, and the etching time is 5 min.

[0053] Step 3, preparing the cathode electrode.

[0054] Put t...

Embodiment 3

[0067] Example 3, fabricating a Schottky diode with an organic ferrodielectric thickness of 450 nm and a ZnS-P (VDF-TrFE) material doped with zinc sulfide nanoparticles as the organic ferrodielectric.

[0068] Step A, for a carrier concentration already at 10 19 cm -3 Epitaxially grown on the substrate with a carrier concentration of 10 15 cm -3 Ga 2 o 3 The epitaxial layer samples were cleaned.

[0069] The specific implementation of this step is the same as step 1 of Embodiment 1.

[0070] Step B, put the cleaned sample face down into the ICP etching reaction chamber, and etch the lower surface of the substrate. The process conditions are: the power of the upper electrode is 100W, the power of the lower electrode is 10W, and the pressure of the reaction chamber is 30Pa , BCl 3 The flow rate of Ar gas is 10 sccm, the flow rate of Ar gas is 20 sccm, and the etching time is 5 min.

[0071] Step C, put the etched sample face down into the electron beam evaporation table to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com