Temperature response type europium ion imprinting composite membrane preparation method and application

A temperature-responsive, europium ion technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as separation difficulties and rare reports of europium ions, and achieve good antibacterial performance, Excellent separation effect and high selective adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

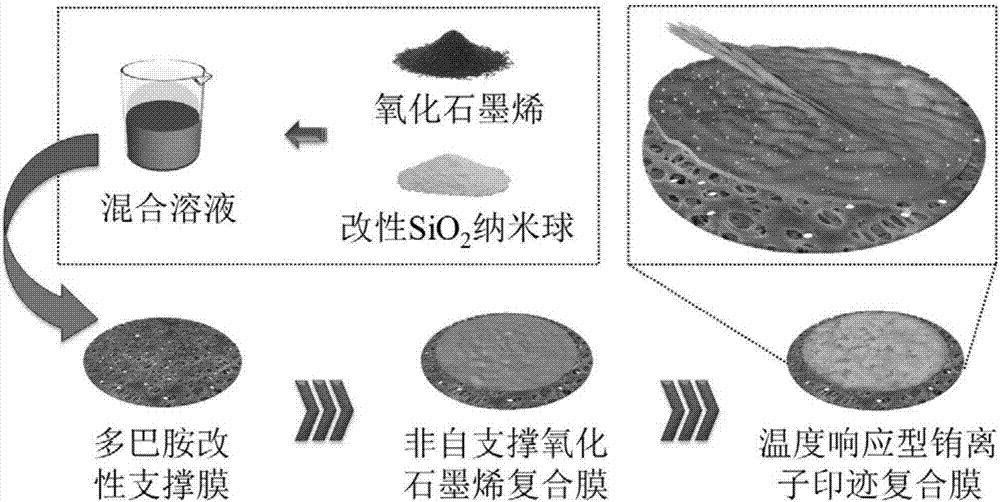

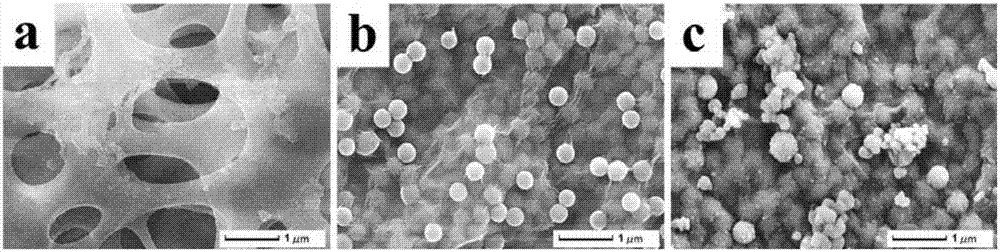

[0048] (1) Modification of regenerated cellulose membrane surface

[0049] First, 0.1211g Tris and 0.2g DA were placed in 100mL deionized water, mixed fully under ultrasonic conditions and adjusted to a pH value of 8.5 to obtain a mixed solution, three pieces of RCMs were immersed in the mixed solution, and reacted for 0 hours at room temperature to obtain a modified For the support membrane dRCMs, take out the modified support membrane, soak and wash it with deionized water three times, 10 minutes each time, and dry the modified support membrane at room temperature after cleaning.

[0050] (2) Preparation of non-self-supporting graphene oxide composite film

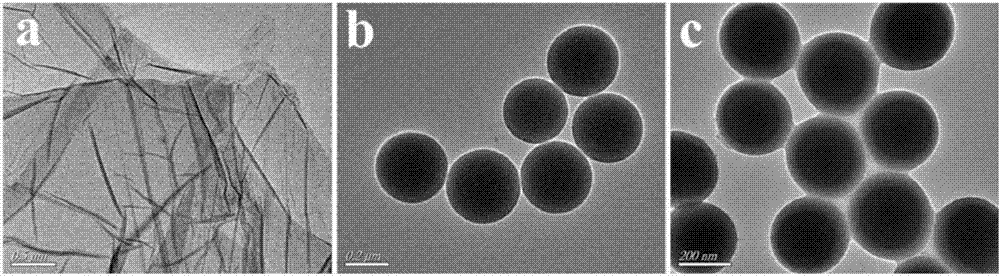

[0051] First, add 0.5g of silica nanospheres with a diameter of ~300nm to 100mL of a mixed solution of ethanol and water (ethanol:water=4:1), add 3mL of KH-570 after passing nitrogen for 5 minutes, and seal it with a degreasing tape. Reaction at 80°C for 16 hours, after centrifugation, the product (kSiO2) was washed wit...

Embodiment 2

[0066] (1) Modification of regenerated cellulose membrane surface

[0067] First, put 0.1211g Tris and 0.2g DA in 100mL of deionized water, mix thoroughly under ultrasonic conditions and adjust the pH value to 8.5 to obtain a mixed solution, immerse 3 pieces of RCMs in the mixed solution, and react at room temperature for 3 hours to obtain a modified For the support membrane dRCMs, take out the modified support membrane, soak and wash it with deionized water three times, 10 minutes each time, and dry the modified support membrane at room temperature after cleaning.

[0068] (2) Preparation of non-self-supporting graphene oxide composite film

[0069] First, add 0.5g of silica nanospheres with a diameter of ~300nm to 100mL of a mixed solution of ethanol and water (ethanol:water=4:1), add 3mL of KH-570 after passing nitrogen for 5 minutes, and seal it with a degreasing tape. Reaction at 80°C for 16 hours, after centrifugation, the product (kSiO2) was washed with alcohol and wat...

Embodiment 3

[0084] (1) Modification of regenerated cellulose membrane surface

[0085] First, put 0.1211g Tris and 0.2g DA in 100mL of deionized water, mix thoroughly under ultrasonic conditions and adjust the pH value to 8.5 to obtain a mixed solution, immerse 3 pieces of RCMs in the mixed solution, and react at room temperature for 6 hours to obtain a modified For the support membrane dRCMs, take out the modified support membrane, soak and wash it with deionized water three times, 10 minutes each time, and dry the modified support membrane at room temperature after cleaning.

[0086] (2) Preparation of non-self-supporting graphene oxide composite film

[0087] First, add 0.5g of silica nanospheres with a diameter of ~300nm to 100mL of a mixed solution of ethanol and water (ethanol:water=4:1), add 3mL of KH-570 after passing nitrogen for 5 minutes, and seal it with a degreasing tape. Reaction at 80°C for 16 hours, after centrifugation, the product (kSiO2) was washed with alcohol and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com