Preparation method and application of carbon-nitrogen doped ternary composite metal oxide based on prussian blue frame material

A framework material, Prussian blue technology, applied in the field of electrochemistry, can solve the problems of rate performance to be improved, slow lithium ion diffusion, capacity decay, etc., to improve reversible specific capacity and cycle stability, improve electrochemical performance, improve electronic The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

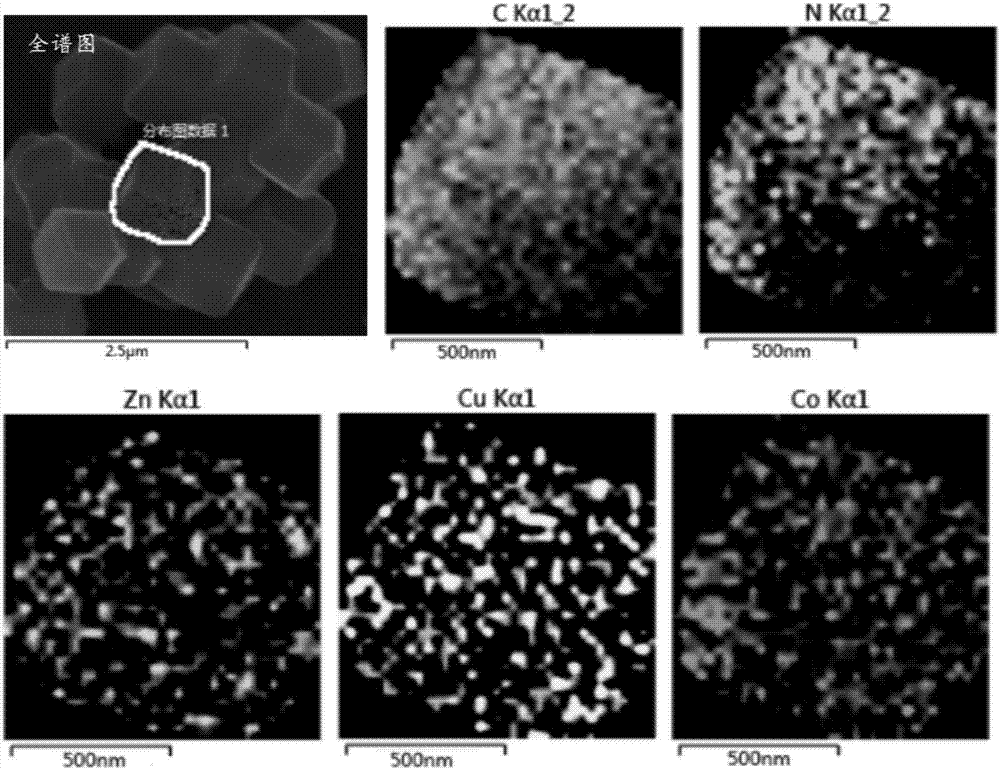

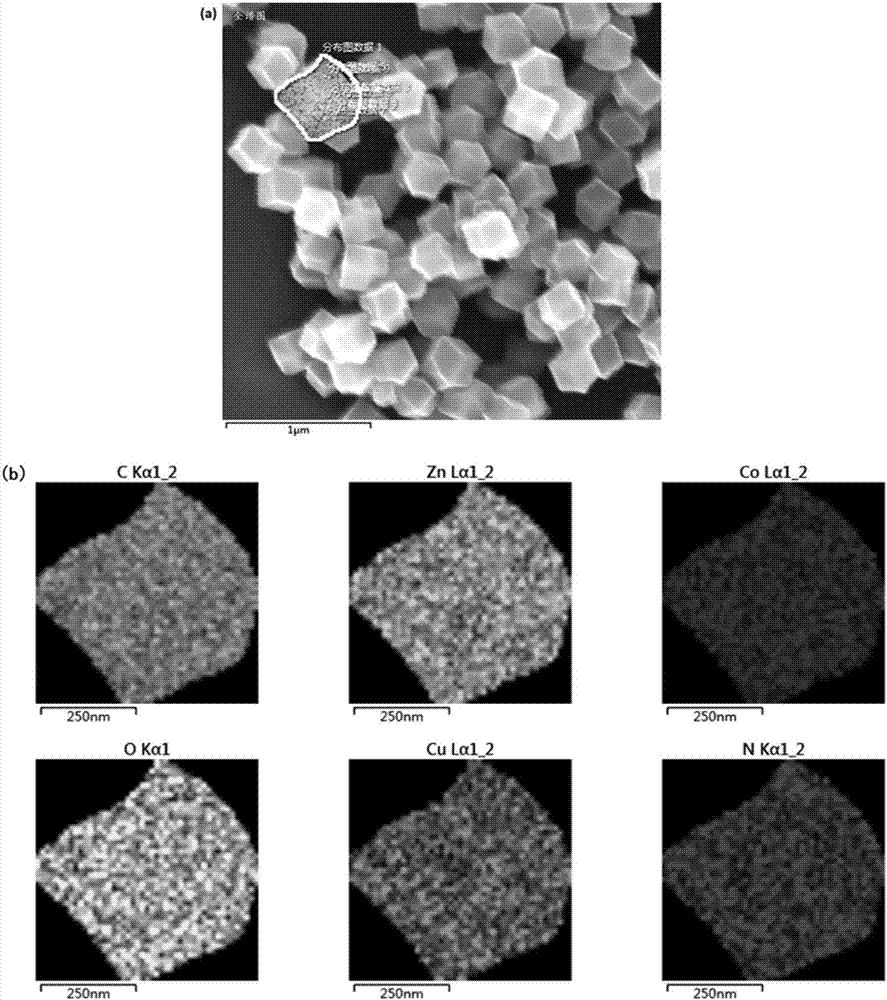

[0037] A method for preparing a carbon-nitrogen doped ternary composite metal oxide based on a Prussian blue frame material, comprising the steps of:

[0038](1) Preparation of ternary Prussian blue frame material:

[0039] At room temperature, solution A is prepared: dissolve 0.04mmol of potassium cobaltcyanide in 15ml of distilled water containing 0.005-0.02mmol of triethylamine;

[0040] (1.2) Solution B preparation: dissolve 0.075mmol of zinc acetate and 0.1-0.6g of high polyvinylpyrrolidone in a mixed solution of 10ml of ethanol and 10ml of distilled water;

[0041] (1.3) Preparation of C solution: dissolve 0.075mmol of copper chloride, 0.05-0.5g of sodium dodecylsulfonate and 0.03-0.4g of cetyltrimethylammonium bromide in 10ml of ethanol and 10ml of distilled water in the mixture;

[0042] (1.4) Then, drop solution B into solution A with a syringe, stir magnetically for 1 hour, put it into a microwave reactor at a temperature of 30-60°C for 30 minutes, and cool to room...

Embodiment 2

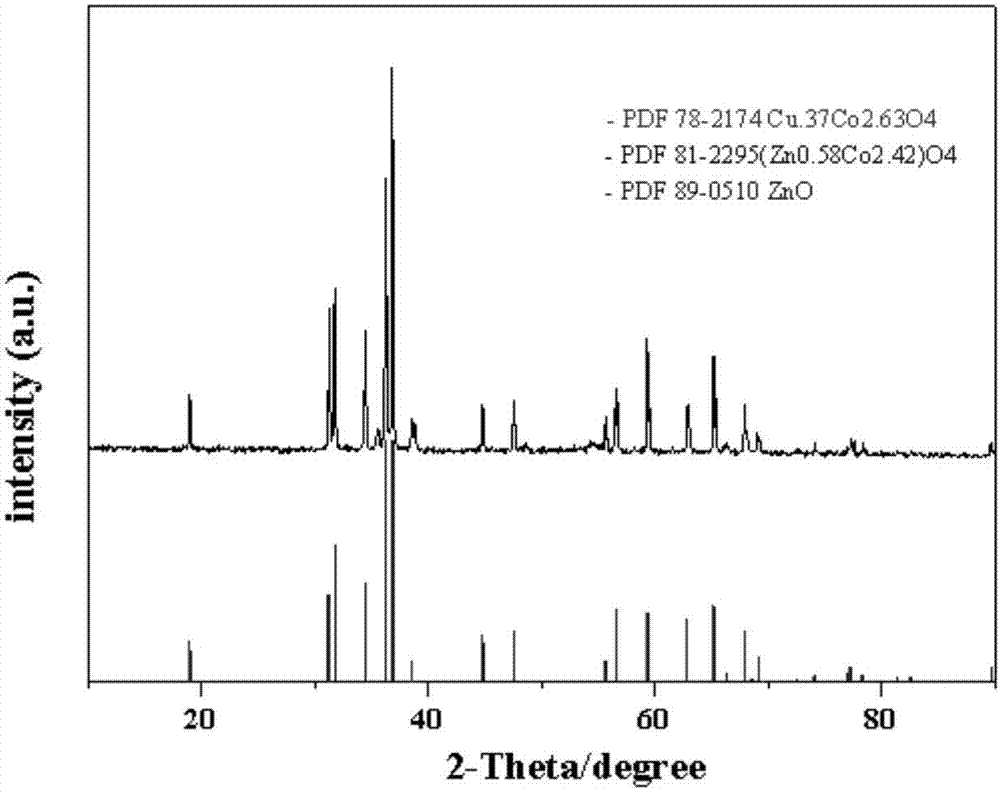

[0050] In this example, the carbon-nitrogen-doped ternary composite metal oxide CuCoO prepared in Example 1 is used 4 / ZnCoO 4 / ZnO is used as the anode material of lithium ion battery, and its electrochemical performance is tested by button simulated battery. The composition of the electrode paste used when assembling the battery includes 70% of the prepared carbon-nitrogen doped ternary composite metal oxide nanocomposite material as the active material, 15% of carbon black and 15% of sodium carboxymethyl cellulose, and the solvent used is ionized water. Mix the electrode slurry with deionized water evenly, and spread it on the copper foil. Dry at 120°C for 12 hours under vacuum. The electrolyte used is a ternary mixed solvent with ethylene carbonate (EC), dimethyl carbonate (DMC) and diethyl carbonate (DEC) at a volume ratio of 1:1:1 and dissolves LiPF 6 (1.0M). A lithium sheet (purity>99.9%) was used as the counter electrode, and Celagrd 2400 was used as the separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com