In-situ control method for form and crystal face of nano cerium oxide

A technology of nano-cerium oxide and control method, which is applied in the field of preparation of rare earth nano-material technology, can solve problems such as difficult removal of new functional groups, performance interference of nano-cerium oxide, and limitation of application fields of nano-cerium oxide, so as to achieve large specific surface area and ease Effect of degree of hard agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

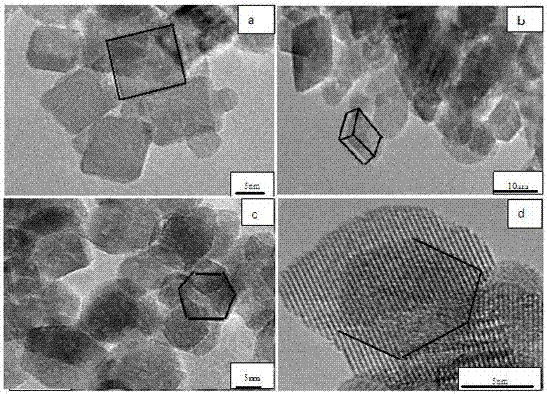

Embodiment 1

[0016] Disperse 5 mg of carbon nanotubes in 100 mL of ethylene glycol by ultrasonic waves, and obtain dispersed and sheared carbon nanotubes after 15 h; in addition, a cerium salt solution with a concentration of 0.5 mol / L was prepared; the dispersed and sheared carbon Nanotubes were added to the cerium salt solution, and an alkaline precipitant was added dropwise to adjust the pH of the system to 9; the above mixed solution was transferred into a polytetrafluoroethylene reactor for solvothermal reaction, the reaction temperature was 160 °C, the reaction time was 12 h, and cooled Afterwards, vacuum freeze-drying was carried out at a drying temperature of -45 °C, a drying time of 15 h, and a vacuum pressure of 40 Pa to obtain a carbon nanotube / cerium precursor composite; the carbon nanotube / cerium precursor composite was placed in a magnetic boat and pushed to In the central area of the corundum reaction tube in a horizontal tube furnace, oxygen was introduced and then heat tr...

Embodiment 2

[0018] Disperse 10 mg of carbon nanotubes in 150 mL of ethanol by ultrasonic waves, and obtain dispersed and sheared carbon nanotubes after 15 h; in addition, a 0.1 mol / L cerium salt solution was prepared; the dispersed and sheared carbon nanotubes were added to In the cerium salt solution, add an alkaline precipitant dropwise at the same time to adjust the pH value of the system to 9.5; move the above mixed solution into a polytetrafluoroethylene reactor for solvothermal reaction, the reaction temperature is 160 °C, the reaction time is 24 h, and vacuum is carried out after cooling. Freeze drying, drying temperature -50 ℃, drying time 20 h, vacuum pressure 45 Pa, to obtain carbon nanotubes / cerium precursor composites; put carbon nanotubes / cerium precursor composites in a magnetic boat and push them to the horizontal tube In the central area of the corundum reaction tube in a type furnace, oxygen was introduced and heat treatment was carried out accordingly. The heating rate ...

Embodiment 3

[0020] Disperse 5 mg of graphene in 100 mL of ethylene glycol by ultrasonic waves, and obtain a uniformly dispersed graphene ethylene glycol suspension after 12 h; prepare a cerium salt solution with a concentration of 0.5 mol / L; The suspension was added to the cerium salt solution, and an alkaline precipitant was added dropwise to adjust the pH of the system to 10; the above mixed solution was transferred into a polytetrafluoroethylene reactor for solvothermal reaction, the reaction temperature was 180 °C, and the reaction time was 24 h. After cooling, carry out vacuum freeze-drying, the drying temperature is -55 ℃, the drying time is 25 h, and the vacuum pressure is 50 Pa to obtain the graphene / cerium precursor composite; the carbon nanotube / cerium precursor composite is placed in a magnetic boat and pushed to In the central area of the corundum reaction tube in a horizontal tube furnace, air was introduced and then heat treated. The heating rate was 10 ℃ / min, the heat trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com