Liquid crystal sealant composition

A liquid crystal sealant and composition technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of affecting the bonding performance of sealants, affecting the service life of liquid crystals, and difficult to control the particle size of fillers. Approximate thermal shrinkage, uniform size, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

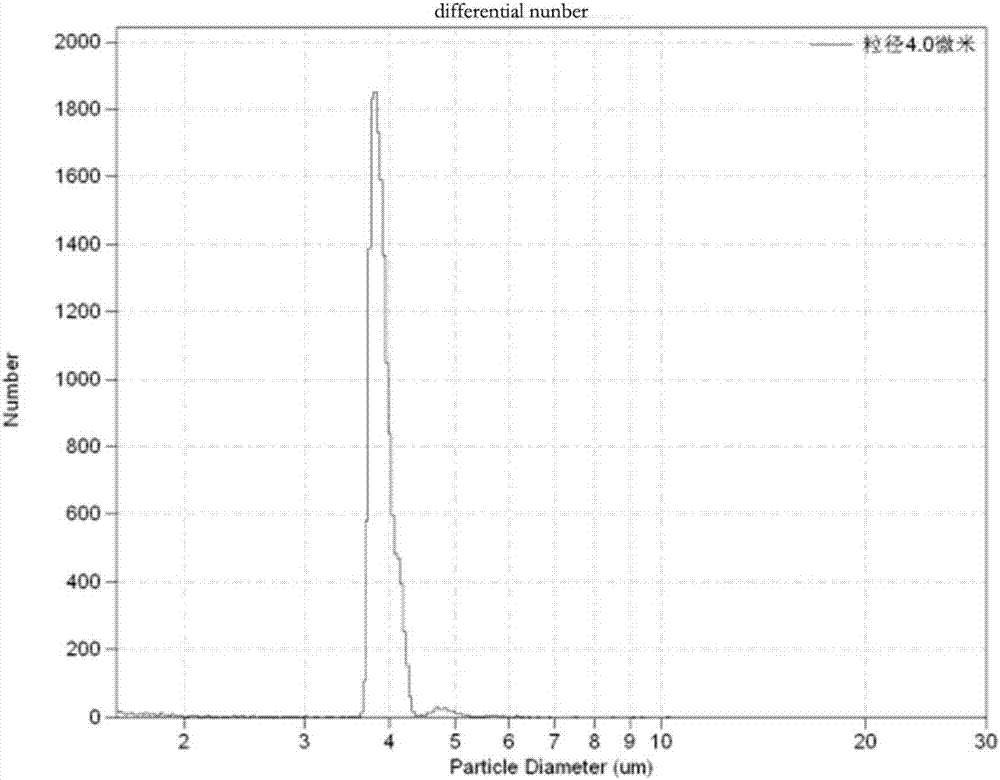

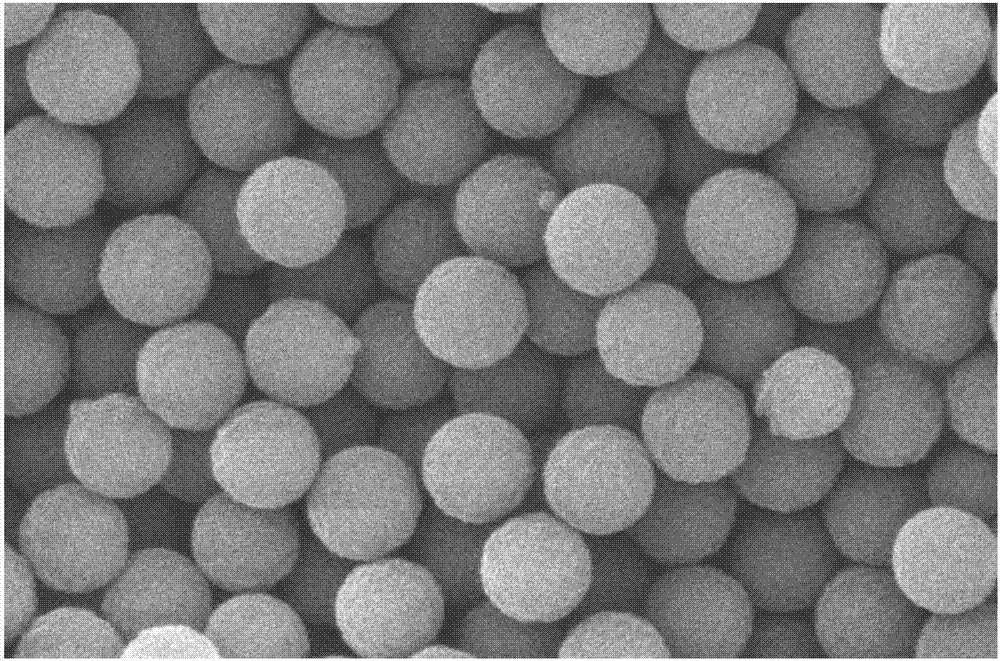

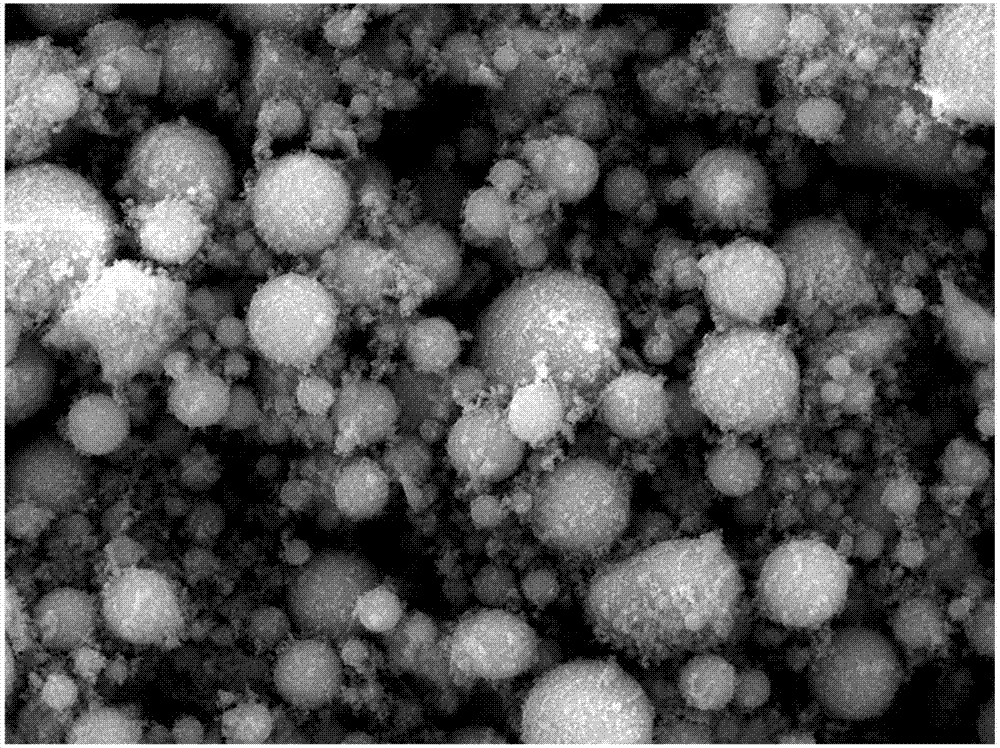

[0046] Preparation of monodisperse polymer microspheres with a particle size of 1 μm: 100 g of styrene (Shanghai Chemical Reagent Company of China Pharmaceutical Group), 3 g of azobisisobutyronitrile (Shanghai Chemical Reagent Company of China Pharmaceutical Group), 20 g of polyvinylpyrrolidone (China Pharm Group Shanghai Chemical Reagent Company), absolute ethanol, etc. were added into a 500ml three-neck flask, stirred until homogeneous, nitrogen gas was introduced to exhaust oxygen for 10 minutes, the water bath was heated to 70°C, the rotation speed of the stirring paddle was kept at 60rpm, and the reaction was carried out for 24 hours. Use a high-speed centrifuge at 5000 rpm for 20 minutes to centrifuge, and wash the microspheres in the lower layer with a mixture of ethanol and water for several times. Seed particles with a particle size of about 1 μm can be obtained.

[0047] Preparation of monodisperse polymer microspheres with a particle size of 2 μm: disperse 50 g of 1...

Embodiment 1

[0052] raw material:

[0053]

[0054] Stir the above-mentioned epoxy resin silane coupling agent and diluent, then add fillers and modified dicyandiamide, stir and disperse, and then grind 3 times on a three-roll mill (Shanghai Shihe Electromechanical Equipment Co., Ltd.) to obtain a liquid crystal sealant combination Object 1.

Embodiment 2

[0056] raw material:

[0057]

[0058] Stir the above-mentioned epoxy resin silane coupling agent and diluent, then add fillers and modified dicyandiamide, stir and disperse, and then grind 3 times on a three-roll mill (Shanghai Shihe Electromechanical Equipment Co., Ltd.) to obtain a liquid crystal sealant combination Object 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com