Method for preparing skin regeneration material loaded with bioactive glass particles

A bioactive glass, skin regeneration technology, applied in the field of dermatology, can solve the problems of repeated operation of growth factors, unstable growth factors, easy degradation, etc., to reduce the proliferation of scars, product cost advantages, and promote healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

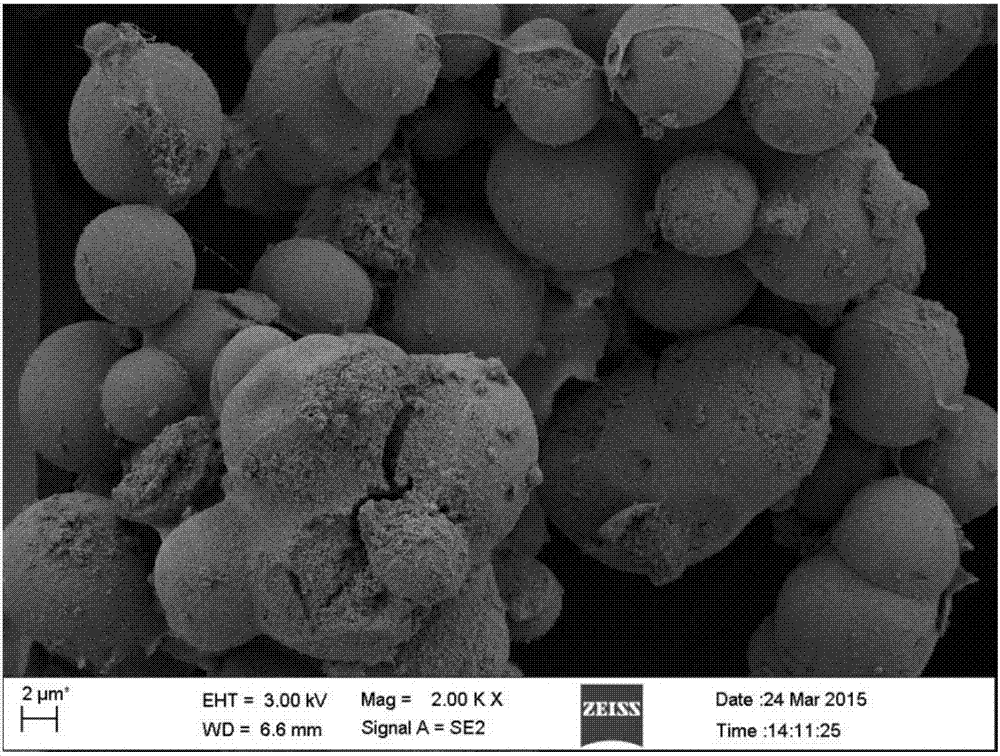

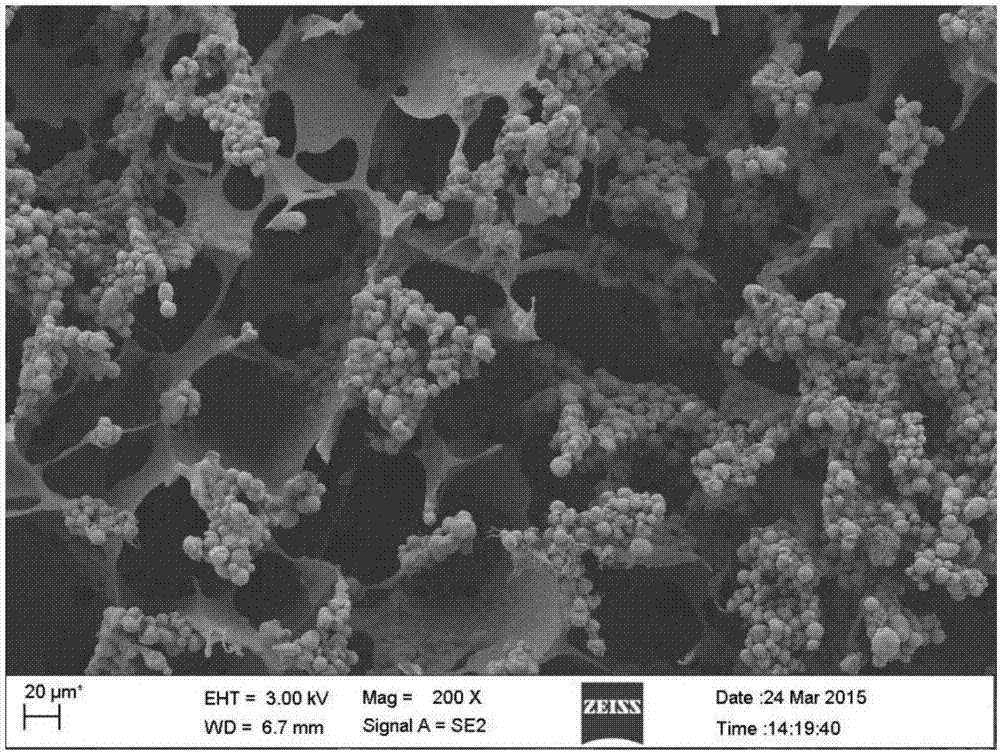

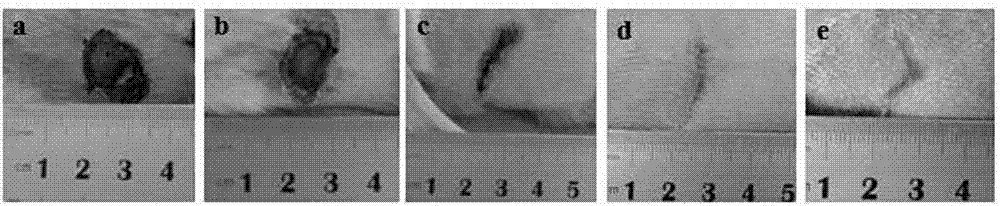

[0028] Hydrolyze ethyl orthosilicate and triethyl phosphate under the catalysis of 2mol / L nitric acid to form a sol, then add calcium nitrate and stir evenly, after aging, drying, grinding, and calcining at 700 degrees Celsius for 2 hours, the glass powder is obtained. After grinding and sieving, bioactive glass particles are obtained. The results of SEM observation of the particle size and morphology of the particles are as follows: figure 1 shown.

[0029] With a mass fraction of 0.05% Na 2 CO 3 The aqueous solution is boiled to treat the raw silk 5 times, 1 hour each time, the temperature is 100°C, and the liquor ratio is 1:100. Fully wash with distilled water, dry naturally to obtain pure silk fiber, use CaCl with a molar ratio of 1:2:8 2 、CH 3 CH 2 Dissolve OH and H2O in a ternary solvent, the mass ratio of solution to raw silk is 10:1, stir and dissolve at 78 degrees Celsius for 1-2 hours to obtain a mixed solution, inject the solution obtained after cooling into a...

Embodiment 2

[0032] Hydrolyze ethyl orthosilicate and triethyl phosphate under the catalysis of 2mol / L nitric acid to form a sol, then add calcium nitrate and stir evenly, after aging, drying, grinding, and calcining at 700 degrees Celsius for 2 hours, the glass powder is obtained , after grinding and sieving to obtain bioactive glass particles.

[0033] With a mass fraction of 0.05% Na 2 CO 3 The aqueous solution was boiled to treat the raw silk 5 times, each time for 1 hour, at a temperature of 100 degrees Celsius and a bath ratio of 1:100, fully washed with distilled water, and dried naturally to obtain pure silk fiber. CaCl with a molar ratio of 1:2:8 2 、CH 3 CH 2 OH and H 2 O ternary solvent is dissolved, the mass ratio of the solution to raw silk is 10:1, stirred and dissolved at 78 degrees Celsius for 1-2 hours to obtain a mixed solution, the solution obtained after cooling is injected into a cellulose dialysis membrane, and dialyzed in running water for 3 days, and the dialyze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com