Lithium vanadium phosphate composite positive electrode material with porous foam and preparation method of lithium vanadium phosphate composite positive electrode material

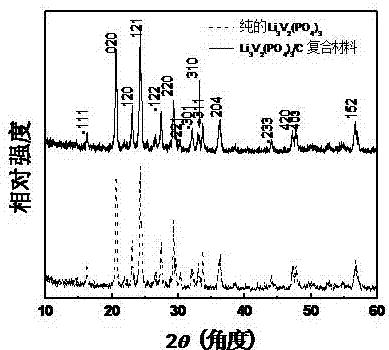

A composite positive electrode material, lithium vanadium phosphate technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problem that the improvement of the tap density of lithium vanadium phosphate cannot be organically unified, and the stability of product performance is difficult to guarantee , Amorphous carbon is difficult to uniformly distribute and other problems, to achieve good electrochemical performance, low cost, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

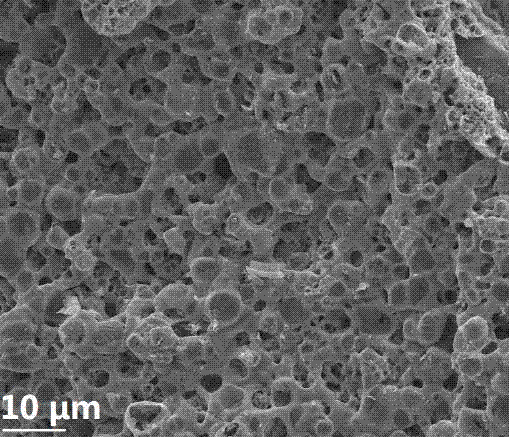

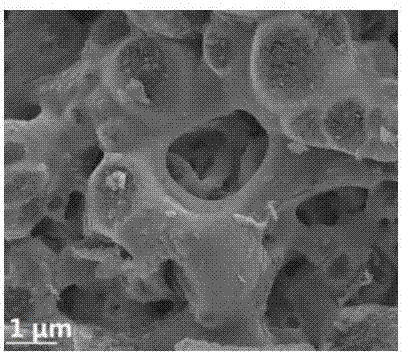

[0035] A preparation method of a lithium vanadium phosphate composite cathode material with porous foam, comprising the following steps:

[0036] S1. Soak sweet potato dregs in dilute nitric acid, then carbonize at a high temperature at 300°C, and then grind for 10 minutes to obtain treated biochar;

[0037] S2. With soluble lithium acetate, vanadium pentoxide, ammonium dihydrogen phosphate as raw material, according to the molar ratio of lithium, vanadium, phosphorus is 3:2:3 be dissolved in deionized water, then add citric acid, citric acid The molar ratio to vanadium is 1:1, placed on a magnetic stirrer, stirred at a temperature of 60°C, and dissolved completely until a clear solution is obtained, and then 20wt% of the biochar treated in step S1 is added, to obtain a mixed solution;

[0038] S3. Put the mixed solution in the step S2 in an oil bath at 200°C, continuously stir the solution at 60 r / min, and simultaneously blow carbon dioxide into the mixed solution with an ai...

Embodiment 2

[0042] A preparation method of a lithium vanadium phosphate composite cathode material with porous foam, comprising the following steps:

[0043] S1. Soak the loofah pulp in dilute nitric acid, then carbonize at a high temperature at 400°C, and then grind for 30 minutes to obtain the treated biochar;

[0044] S2. With soluble lithium nitrate, vanadium pentoxide, ammonium dihydrogen phosphate as raw materials, according to the molar ratio of lithium, vanadium, phosphorus is 3:2:3 dissolved in deionized water, then add citric acid, citric acid The molar ratio to vanadium is 2:1, placed on a magnetic stirrer, stirred at a temperature of 60°C, and dissolved completely until a clear solution is obtained, and then 20wt% of the biochar treated in step S1 is added, to obtain a mixed solution;

[0045] S3. Put the mixed solution in the step S2 in an oil bath at 250°C, continuously stir the solution at 80 r / min, and blow nitrogen into the mixed solution through the regulating valve thr...

Embodiment 3

[0049] A preparation method of a lithium vanadium phosphate composite cathode material with porous foam, comprising the following steps:

[0050] S1. The square melon pulp was soaked in dilute nitric acid, then carbonized at a high temperature at 500°C, and then ground for 20 minutes to obtain the treated biochar;

[0051] S2. With soluble lithium acetate, vanadium pentoxide, ammonium dihydrogen phosphate as raw materials, according to the molar ratio of lithium, vanadium, phosphorus is 3:2:3 dissolved in deionized water, then add citric acid, citric acid The molar ratio to vanadium is 3:1, placed on a magnetic stirrer, stirred at a temperature of 60°C, and dissolved completely until a clear solution is obtained, and then 20wt% of the biochar treated in step S1 is added, to obtain a mixed solution;

[0052] S3. Put the mixed solution in step S2 in an oil bath at 100°C, stir the solution continuously at 70 r / min, and at the same time blow argon and helium into the mixed soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com