Lithium ion battery composite positive electrode material, and preparation method and application thereof

A composite positive electrode material and lithium-ion battery technology, which is applied in battery electrodes, secondary batteries, hybrid capacitor electrodes, etc., can solve problems affecting applications, poor conductivity and rate performance, and achieve simple and easy-to-control operation steps, excellent Mechanical properties, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: LiNi1 / 3 co 1 / 3 mn 1 / 3 o 2 preparation of

[0029] With Li(CH 3 COO)·2H 2 O is the lithium source, Ni(CH 3 COO) 2 4H 2 O, Co(CH 3 COO) 2 4H 2 O, Mn(CH 3 COO) 2 4H 2 O is Ni source, Co source, Mn source respectively; According to molar ratio Li:(Ni+Co+Mn)=1.1:1 (wherein the molar ratio of Ni:Co:Mn is 1:1:1) weigh corresponding raw material In 50ml deionized water, use this mixed solution as liquid A; then weigh citric acid equimolar to the total metal ions, and dissolve it together with ethylene glycol (the molar ratio of citric acid and ethylene glycol is 1:3) Use 50ml of alcohol as liquid B; add liquid A dropwise into liquid B, and use a water bath to stir magnetically at 60°C to allow citric acid to coordinate with metal ions; after the addition is complete, heat up to 95°C to make the citric acid complex Esterification occurs with ethylene glycol, and the solution becomes a wet gel at this time; then the wet gel is dried in a vacuum drying ove...

Embodiment 2

[0030] Embodiment 2: the preparation of three-dimensional graphene

[0031] (1) 10g acrylic acid type cation exchange resin in 100ml 0.05mol L -1 Soak in nickel acetate solution for 6h;

[0032] (2) Wash the soaked resin to neutral with deionized water, and dry at 60°C for 12 hours;

[0033] (3) Mix the dried resin with ethanol containing 40g KOH, and stir at 80°C until the mixture becomes an inkpad-like mixture;

[0034] (4) Dry the mixture in a drying oven at 70°C for 48 hours, and pulverize the obtained product with a pulverizer;

[0035] (5) Raise the pulverized material to 850°C at a heating rate of 2°C / min under a nitrogen atmosphere, and keep it at 850°C for 2 hours;

[0036] (6) Add the carbonized product to an excess of 3mol L -1 In the HCl, stir more than 12h;

[0037] (7) The stirred product was washed with deionized water until the pH was 7, and dried at 70° C. for 12 hours to obtain the product.

Embodiment 3

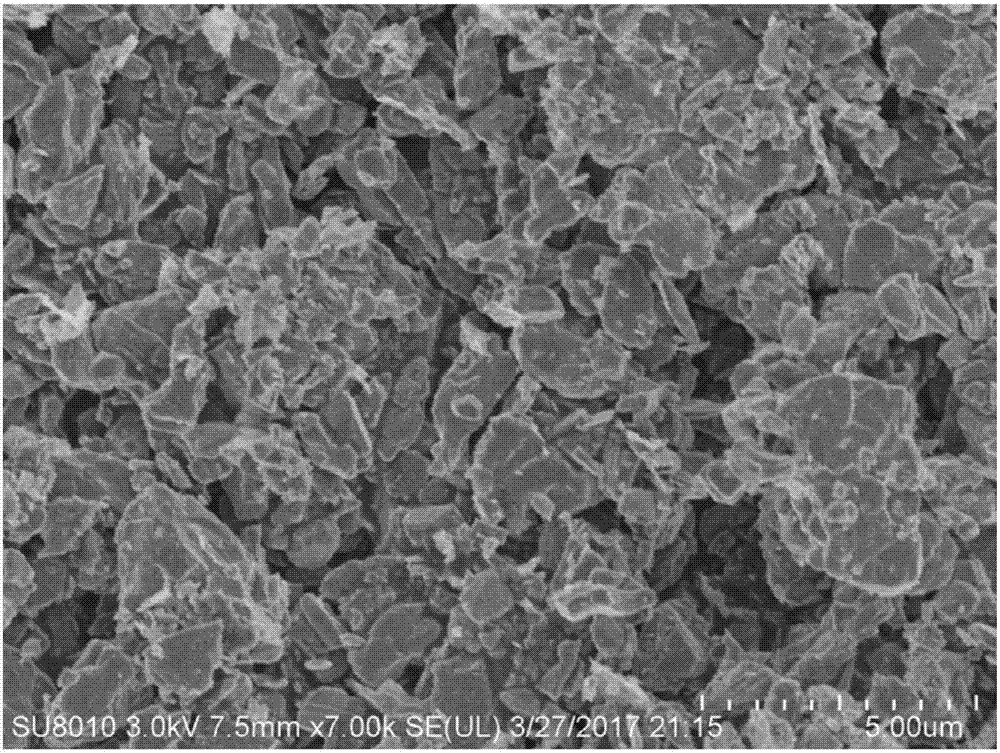

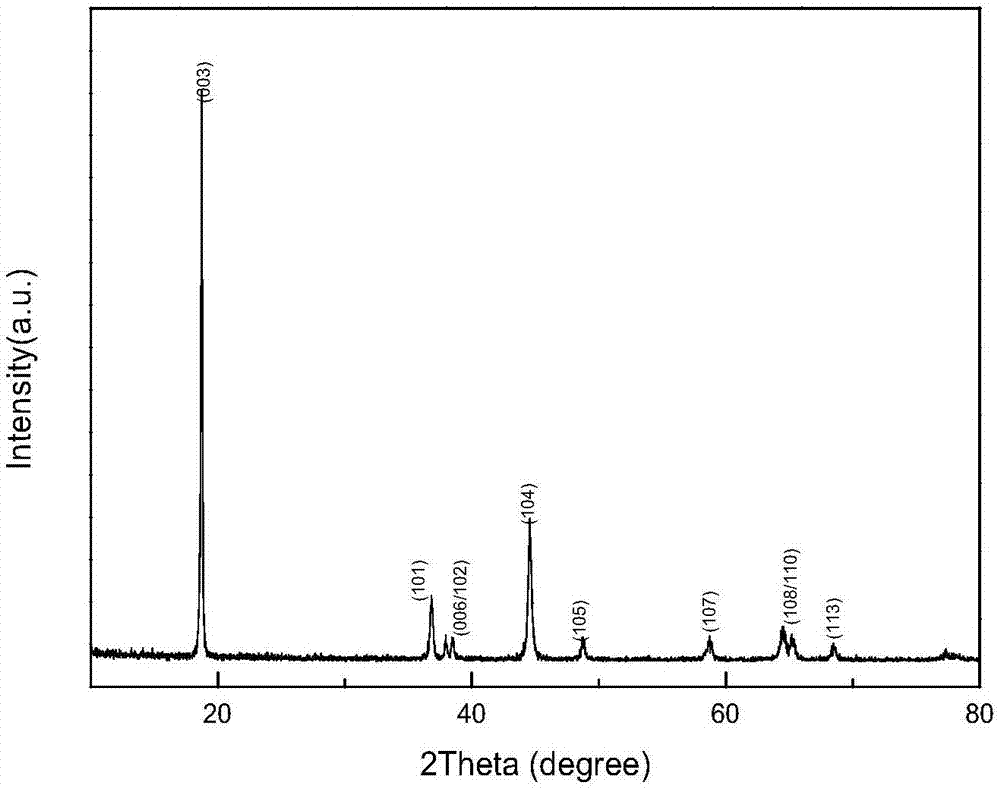

[0038] Example 3: LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 / Three-dimensional graphene synthesis and electrode preparation

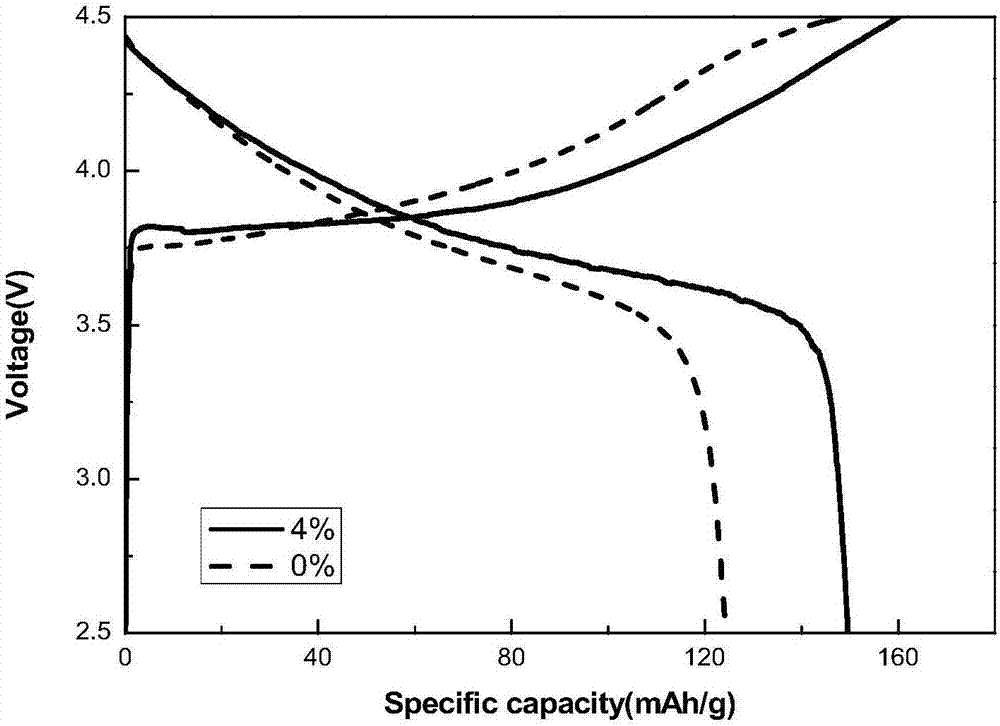

[0039] LiNi prepared in Example 1 1 / 3 co 1 / 3 mn 1 / 3 o 2 The three-dimensional graphene prepared in Example 2 with a mass fraction of 4% was added to the powder, and LiNi was prepared by mixing ball milling on a high-energy ball mill under nitrogen protection for 6h (850r / min, the ball-to-material ratio was 4:1). 1 / 3 co 1 / 3 mn 1 / 3 o 2 / 3DHPG composite material, the morphology and structure of the composite material are as follows figure 1 and figure 2 Mix the composite material with binder (CMC:SBS=1:1) and conductive agent (acetylene black) at a mass ratio of 8:1:0.45 as shown, add deionized water and stir for 5 hours to obtain a slurry; the slurry The material was evenly coated on aluminum foil, and after drying, it was transferred to a vacuum oven at 100°C for 24 hours. Punch the fabricated pole piece into discs made of activated carbon Copper foi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com