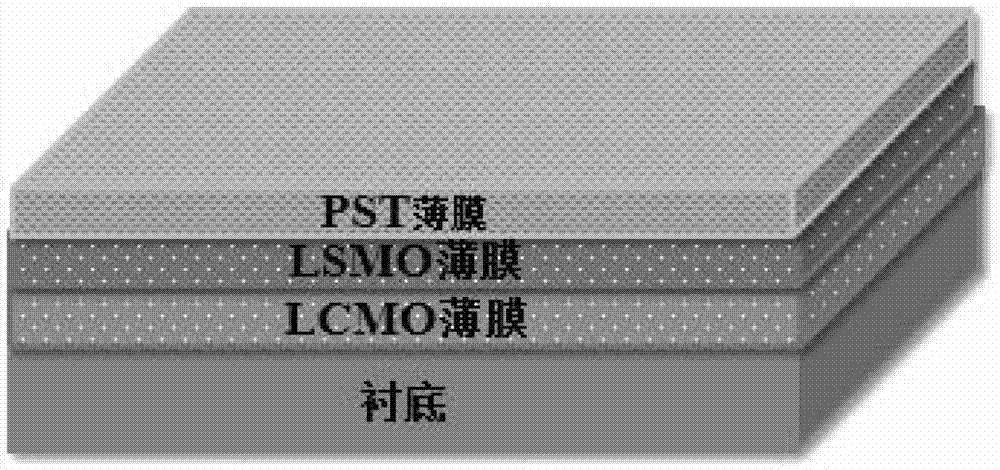

Lanthanum calcium manganese oxygen-lanthanum strontium manganese oxygen-lead strontium titanate composite film and preparation method thereof

A technology of lanthanum calcium manganese oxide thin film, strontium lead titanate, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of obtaining magneto-capacitance effect, etc. Easy to control and beneficial to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The following examples illustrate the preparation method of the composite film, which may specifically include the following steps.

[0031] Substrate cleaning and pretreatment. First place the substrate in acetone, ethanol and water for ultrasonic cleaning to remove dust or other impurities on the surface of the substrate, and then preferably anneal in a rapid annealing furnace to enhance the surface activity of the substrate.

[0032] Preparation of precursor solution.

[0033] Add lanthanum acetate, calcium acetate and manganese acetate into the mixed liquid solvent composed of acetic acid and water in molar ratio, and heat to reflux to completely dissolve the solvent. Then, add an appropriate amount of stabilizer acetylacetone to the mixed solution, and heat to reflux. Finally, the mixed solution is filtered to obtain a stable lanthanum calcium manganese oxide precursor solution. The molar ratio of the three solutes of lanthanum acetate, strontium acetate and man...

Embodiment

[0041] (1) Cleaning of silicon substrate

[0042] First, blow off the pollutants on the surface of the silicon substrate with nitrogen, and then place the silicon wafer in acetone, ethanol and deionized water for 10 minutes to ultrasonically clean it. After the substrate is cleaned, dry it at 450°C and let it cool naturally for later use;

[0043] (2) Preparation of precursor solution

[0044] Dissolve lanthanum acetate, calcium acetate and manganese acetate with a molar ratio of La:Ca:Mn of 0.7:0.3:1 in a mixed solvent of acetic acid and deionized water, heat to 60-80°C to completely dissolve the solute, and then add Mixture acetylacetone, and continue to heat to make the solute react completely, the volume ratio of acetic acid and acetylacetone is 5:1:1, the concentration of manganese element in the solution is 0.15M / L, and the obtained solution is placed at room temperature for 72-96h, with 0.2 Filter the solution with a micron microporous filter to obtain a stable LCMO fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com