Lithium-oxygen secondary battery cathode and preparation method thereof, lithium-oxygen secondary battery

A secondary battery, battery cathode technology, applied in fuel cell type half cells and secondary battery type half cells, battery electrodes, circuits, etc. The problem of poor mass transfer ability, etc., can achieve the effect of reducing the performance degradation and short circuit phenomenon of air batteries, broad application prospects, and strong hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

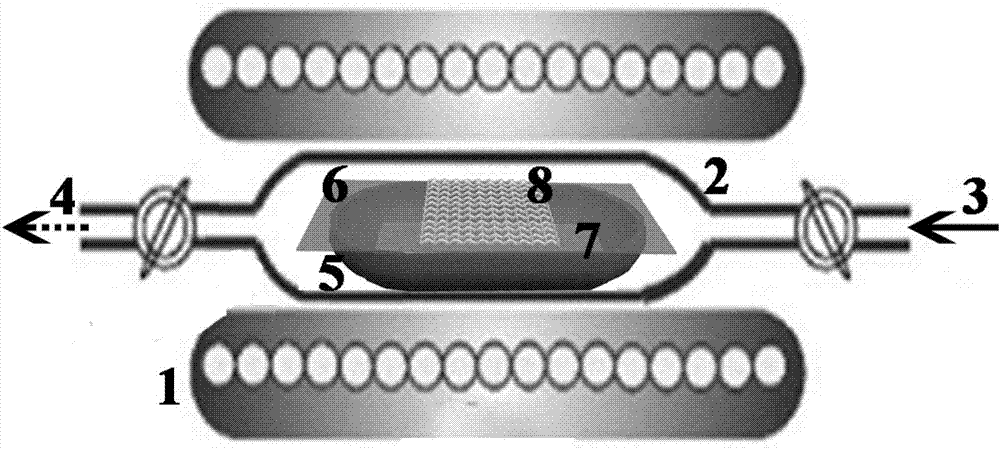

[0063] The invention provides a method for preparing a positive electrode of a lithium-oxygen secondary battery, comprising the following steps:

[0064] A) Under a protective atmosphere, place the mesh metal material on top of the melamine, and after roasting, obtain the positive electrode of the lithium-oxygen secondary battery.

[0065] In order to improve the performance of the manufactured product and the integrity of the overall process route, and reduce the influence of impurities and oil stains on the raw materials, the reticular metal material is preferably a pre-treated reticular metal material. The present invention has no particular limitation on the specific steps of the pretreatment, the pretreatment steps of metal materials well known to those skilled in the art can be used, and those skilled in the art can select and adjust according to actual production conditions, raw material conditions and product requirements, The pretreatment step in the present invention...

Embodiment 1

[0093] Step 1: Take a piece of stainless steel mesh, and use dilute hydrochloric acid and absolute ethanol to clean the stainless steel mesh several times;

[0094] Step 2: Weigh 2 grams of melamine solid powder and put it into a ceramic ark. Cover the ceramic ark with a piece of carbon paper, place the cleaned stainless steel mesh on the carbon paper, and put the whole into a high-temperature tube furnace;

[0095] The third step: using argon as the protective gas, start the tube furnace to heat up to 750 degrees Celsius at a rate of 5 degrees Celsius / minute, and keep at this temperature for 2 hours;

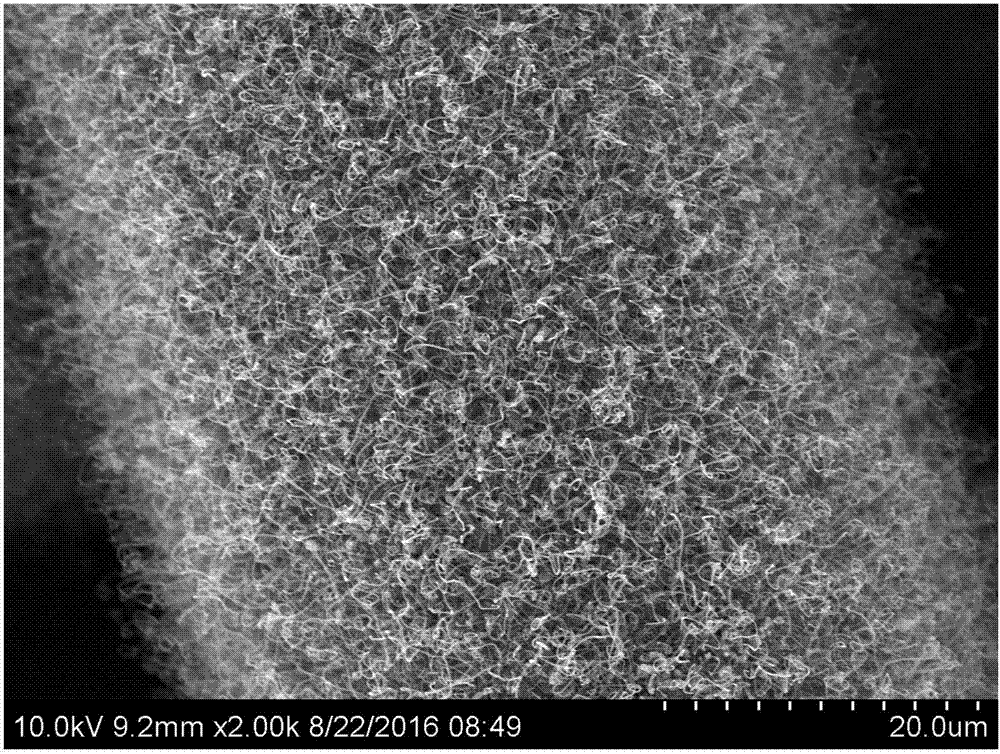

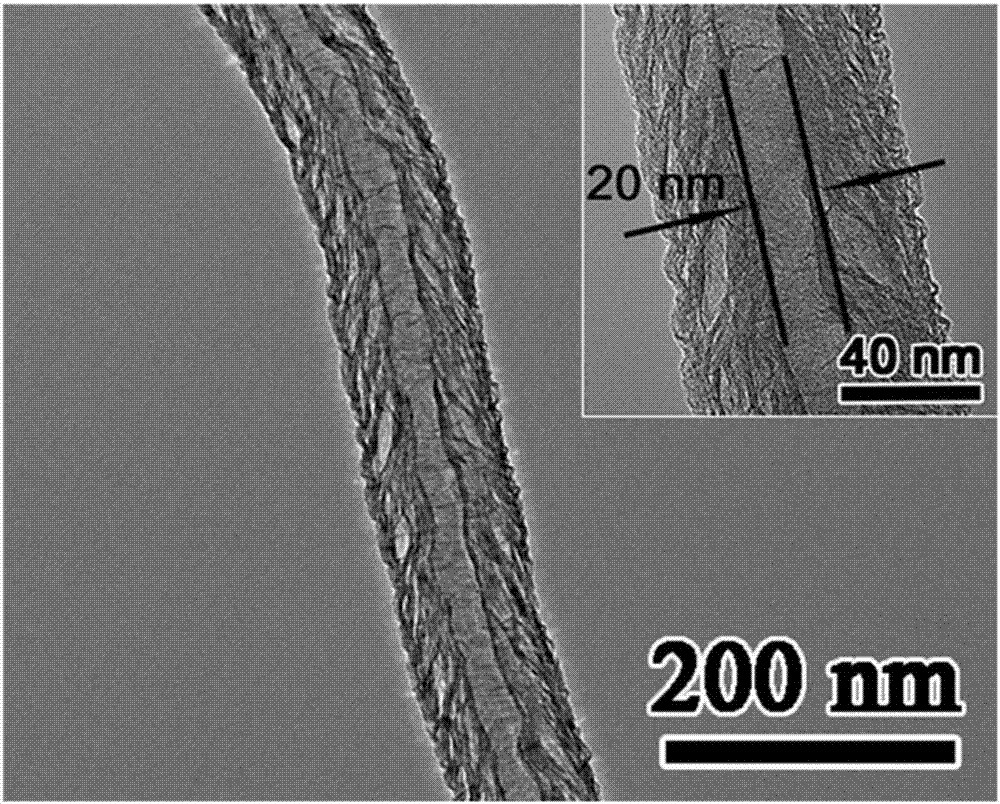

[0096] Step 4: After heating, wait for the reactant to cool down to room temperature, take out the stainless steel mesh, wash it several times with distilled water and absolute ethanol respectively, and after drying in the air, the surface of the stainless steel mesh is covered with a layer of black matter, which is the nitrogen-doped Carbon nanotubes@stainless steel mesh integ...

Embodiment 2

[0102] Step 1: Take a piece of stainless steel mesh, and use dilute hydrochloric acid and absolute ethanol to clean the stainless steel mesh several times;

[0103] Step 2: Weigh 2 grams of melamine solid powder and put it into a ceramic ark. Cover the ceramic ark with a piece of carbon paper, place the cleaned stainless steel mesh on the carbon paper, and put the whole into a high-temperature tube furnace;

[0104] The third step: using argon as the protective gas, start the tube furnace to heat up to 800 degrees Celsius at a rate of 5 degrees Celsius / minute, and keep at this temperature for 2 hours;

[0105] Step 4: After heating, wait for the reactant to cool down to room temperature, take out the stainless steel mesh, wash it several times with distilled water and absolute ethanol respectively, and after drying in the air, the surface of the stainless steel mesh is covered with a layer of black matter, which is the nitrogen-doped Carbon nanotubes@stainless steel mesh integ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com