Cathode modified plane perovskite solar energy cell and preparation method thereof

A solar cell and cathode modification technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of device performance degradation, achieve the effects of reducing series resistance, simplifying the preparation process, and improving fill factor and current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

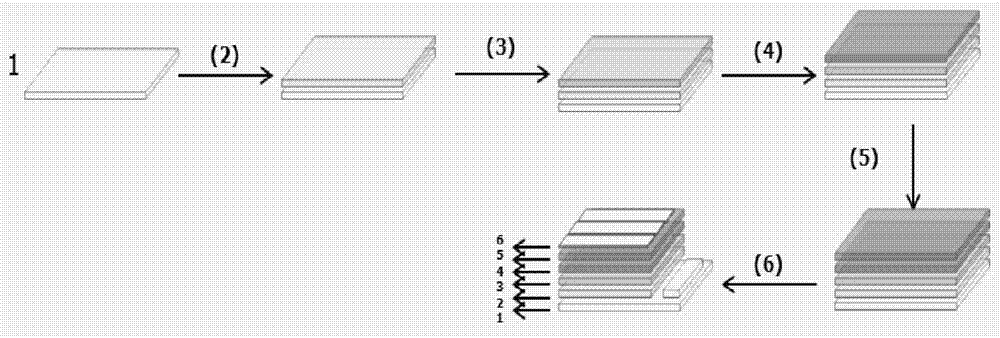

[0039] Such as figure 1 As shown, in this embodiment, a method for preparing a high-efficiency non-inhibited planar perovskite solar cell by modifying the cathode interface of an alcohol solution comprises the following steps in turn:

[0040] (1) The ITO transparent conductive glass is etched into the desired target pattern by laser, and then the etched conductive substrate is ultrasonically cleaned with conventional detergent aqueous solution, deionized water, acetone and isopropanol for 20 minutes, and then Blow dry with nitrogen to obtain a clean conductive substrate for later use;

[0041](2) Treat the surface with plasma (plasma, using a conventional plasma cleaning machine) for 10 minutes to hydrophilize the surface before use. The polymer semiconductor hole transport material is poly 3,4-ethylenedioxythiophene and polystyrene Sulfonate (PEDOT:PSS) (model: PEDOT AL4083) was spin-coated on the conductive substrate, the spin-coating speed was 3000rpm / min, the spin-coatin...

Embodiment 2

[0055] Such as figure 1 As shown, a method for preparing a highly efficient non-inhibited planar perovskite solar cell by modifying the cathode interface of an alcohol solution in this embodiment comprises the following steps:

[0056] (1) The FTO transparent conductive glass is etched into the desired target pattern by laser, and then the etched conductive substrate is ultrasonically cleaned with conventional detergent aqueous solution, deionized water, acetone and isopropanol for 20 minutes, and then Blow dry with nitrogen to obtain a clean conductive substrate for later use;

[0057] (2) Treat the surface with plasma (plasma, using a conventional plasma cleaning machine) for 10 minutes to hydrophilize the surface before use. The polymer semiconductor hole transport material is poly 3,4-ethylenedioxythiophene and polystyrene Sulfonate (PEDOT:PSS) (model: PEDOT AL4083) was spin-coated on the conductive substrate, the spin-coating speed was 3000rpm / min, the spin-coating time ...

Embodiment 3

[0064] Such as figure 1 As shown, a method for preparing a highly efficient non-inhibited planar perovskite solar cell by modifying the cathode interface of an alcohol solution in this embodiment comprises the following steps:

[0065] (1) The ITO transparent conductive glass is etched into the desired target pattern by laser, and then the etched conductive substrate is ultrasonically cleaned with conventional detergent aqueous solution, deionized water, acetone and isopropanol for 20 minutes, and then Blow dry with nitrogen to obtain a clean conductive substrate for later use;

[0066] (2) Treat the surface with plasma (plasma, using a conventional plasma cleaning machine) for 10 minutes to hydrophilize the surface before use. The polymer semiconductor hole transport material is poly 3,4-ethylenedioxythiophene and polystyrene Sulfonate (PEDOT:PSS) (model: PEDOT AL4083) was spin-coated on the conductive substrate, the spin-coating speed was 3000rpm / min, the spin-coating time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com