Direct feeding type biological fermentation feed additive and preparation method and application thereof

A bio-fermentation feed and additive technology, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve problems such as improper use of bacteria, poor basic conditions, and complicated sources of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

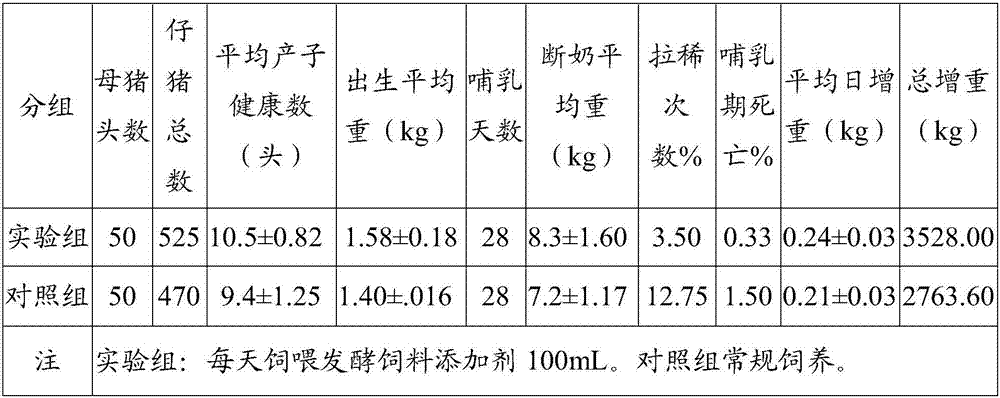

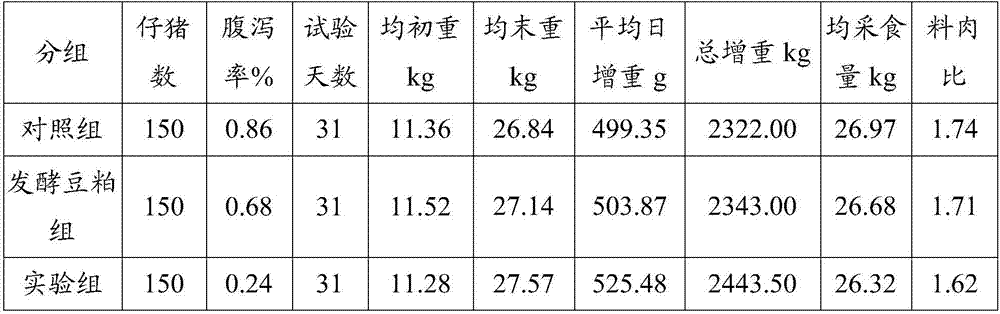

Examples

Embodiment 1

[0071] Embodiment 1 Preparation of a direct-throwing type bio-fermentation feed additive

[0072] 1. Preparation of auxiliary materials: Commercially purchased soybean meal, wheat, and corn are routinely tested according to the feed standard, and then mixed according to the weight ratio of 6:1:3, then crushed, passed through a 80-mesh sieve, and passed through a drum dryer at high temperature (120-150°C) Dry and set aside.

[0073] 2. Preparation of lactic acid bacteria culture medium and bacteria powder:

[0074] (1) Medium preparation: Bifidobacterium solid medium was prepared as follows: peptone 5.0g, beef extract 5.0g, tryptone 10.0g, yeast powder 5.0g, glucose 8.0g, Tween 80 1.0g, K 2 HPO 4 2.0g, sodium acetate 5.0g, diammonium hydrogen citrate 2.0g, ZnSO 4 ·7H 2 O 0.25g, MgSO 4 ·7H 2 O 0.1g, distilled water to 1L, pH 6.2-6.4, autoclaved at 121°C for 20 minutes, the preparation of bifidobacterium liquid medium is the same as that of solid medium, but without adding...

Embodiment 2

[0092] Embodiment 2 Preparation of a direct-throwing type bio-fermentation feed additive

[0093] 1. Preparation of auxiliary materials: Commercially purchased soybean meal, wheat, and corn are routinely tested according to the feed standard and then mixed according to the weight ratio of 8:2:3, then crushed, passed through a 100-mesh sieve, and passed through a drum dryer at high temperature (120-150°C) Dry and set aside.

[0094] 2. Preparation of lactic acid bacteria culture medium and bacteria powder:

[0095] (1) Medium preparation: Bifidobacterium solid medium was prepared as follows: peptone 5.0g, beef extract 5.0g, tryptone 10.0g, yeast powder 5.0g, glucose 8.0g, Tween 80 1.0g, K 2 HPO 4 , agar 15.0g, 2.0g, sodium acetate 5.0g, diammonium hydrogen citrate 2.0g, ZnSO 4 ·7H 2 O 0.25g, MgSO 4 ·7H 2 O 0.1g, distilled water to 1L, pH 6.2-6.4, autoclaved at 121°C for 20 minutes, the preparation of bifidobacterium liquid medium is the same as that of solid medium, but w...

Embodiment 3

[0113] Embodiment 3 Preparation of a direct-throwing type bio-fermentation feed additive

[0114]1. Preparation of auxiliary materials: Commercially purchased soybean meal, wheat, and corn are routinely tested according to the feed standard and then mixed according to the weight ratio of 5:1:5, then crushed, passed through a 80-mesh sieve, and passed through a drum dryer at high temperature (120-150°C) Dry and set aside.

[0115] 2. Preparation of lactic acid bacteria culture medium and bacteria powder:

[0116] (1) Medium preparation: Bifidobacterium solid medium was prepared as follows: peptone 5.0g, beef extract 5.0g, tryptone 10.0g, yeast powder 5.0g, glucose 8.0g, Tween 80 1.0g, K 2 HPO 4 , agar 15.0g, 2.0g, sodium acetate 5.0g, diammonium hydrogen citrate 2.0g, ZnSO 4 ·7H 2 O 0.25g, MgSO 4 ·7H 2 O 0.1g, distilled water to 1L, pH 6.2-6.4, autoclaved at 121°C for 20 minutes, the preparation of bifidobacterium liquid medium is the same as that of solid medium, but wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com