A large particle size recyclable heavy metal adsorption functional microsphere and its application

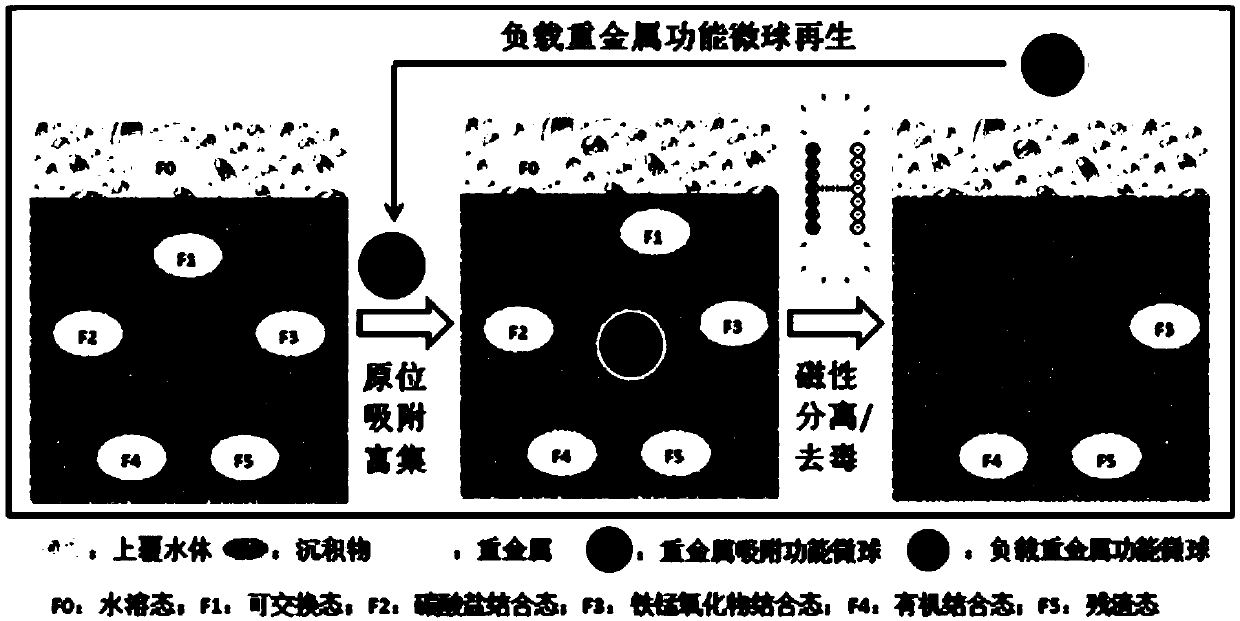

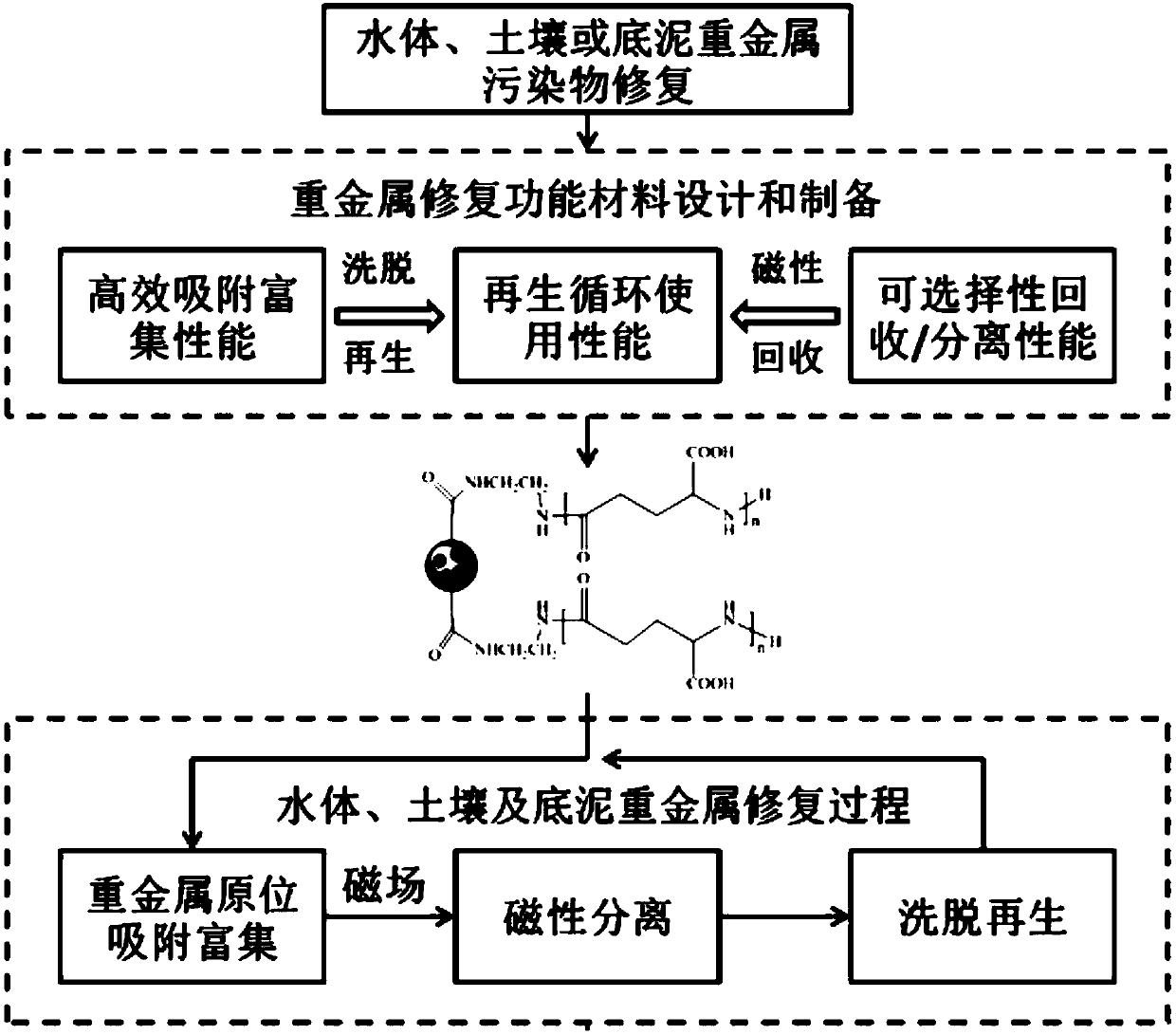

A technology with large particle size and heavy metals, applied in the directions of alkali metal compounds, adsorbed water/sewage treatment, alkali metal oxides/hydroxides, etc. Set performance, avoid water impact, not easy to corrode effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

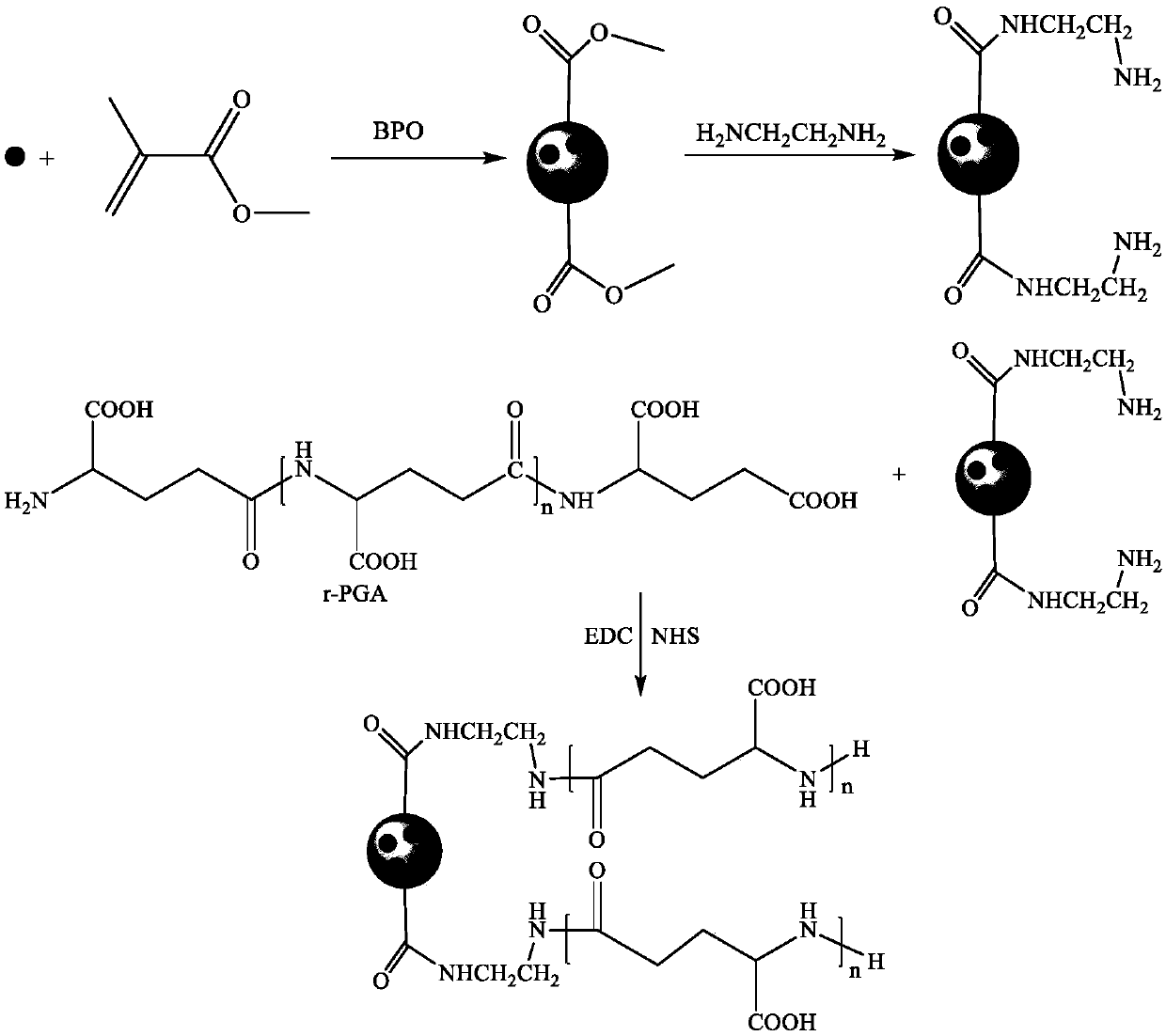

[0035] The preparation method of the recyclable heavy metal adsorption functional microspheres with large particle size comprises the following steps:

[0036] 1) preparing ferroferrofluid;

[0037] 2) In ferric oxide (Fe 3 o 4 ) under the condition that magnetic fluid exists, take methyl methacrylate (MMA) as monomer, carry out dispersion polymerization reaction, obtain Fe 3 o 4 @PMMA magnetic microspheres;

[0038] 3) Fe 3 o 4 @PMMA magnetic microspheres modify ethylenediamine to obtain Fe 3 o 4 @PMMA@EDA microspheres;

[0039] 4) Fe 3 o 4 @PMMA@EDA microspheres modify polyglutamic acid to obtain Fe 3 o 4 @PMMA@EDA@r-PGA functional microspheres.

[0040] Preferably, in step 1), the ferroferric oxide ferrofluid is prepared by co-precipitation method of ferrous iron salt and ferric iron salt.

[0041] Preferably, in step 2), the polymethyl methacrylate microspheres are in the presence of ferroferrofluid, with methyl methacrylate as a monomer and benzoyl peroxide ...

Embodiment 1

[0050] Embodiment 1: Synthesis of functional microspheres

[0051] ① Fe 3 o 4 Preparation of @PMMA microspheres:

[0052] 1) Preparation of ferrofluid

[0053] Fe was prepared by chemical co-precipitation 3 o 4 Ferrofluid, namely Fe 2+ and Fe 3+ solution as n(Fe 2+ ):n(Fe 3+ )=1:1.65 ratio, under the condition of over-alkaline, stirred and reacted at 70°C for one hour to carry out the precipitation reaction, after cleaning the above-mentioned particles, the surfactant oleic acid was coated to improve the dispersibility of the particles.

[0054] 2) Preparation of magnetic microspheres

[0055] Using low-speed stirring suspension polymerization, 10ml of 0.058g / ml Fe coated with homemade oleic acid 3 o 4 Magnetic fluid was added to 25ml MMA dispersion polymerization system, polyvinyl alcohol (PVA 1788) and basic magnesium carbonate were used as stabilizer and auxiliary dispersant, benzoyl peroxide (BPO) was used as initiator, and methyl dimethacrylate was used as cros...

example 2

[0061] Example 2: Application of functional microspheres

[0062] ①Simulation experiment of in situ remediation of heavy metals in water combined with magnetic separation

[0063] Add 20 mg of the functional microspheres prepared above into 25 ml of 200 mg / L lead solution, put them into a 250 ml wide-mouth bottle, stir and mix them evenly, seal the sample and place it in a constant temperature shaker (25 ° C), simulate During the in-situ repair process, the shaking table was adsorbed for 12 hours (150rpm). The rare earth strong magnet is used to realize 100% recovery of the functional microspheres, and the concentration of the adsorbed water sample is measured by means of atomic absorption, and the amount of Pb adsorption and removal is calculated.

[0064] ②Recycling of functional microspheres

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com