Calcium-containing water-soluble compound fertilizer and preparation process thereof

A compound fertilizer and preparation process technology, which is applied in the preparation of organic fertilizers, calcareous fertilizers, urea compound fertilizers, etc., can solve the problems of increasing the incidence of soil-borne diseases, easy mildew, and low hydrolysis rate of soybean meal protein, and achieves good results. It is beneficial to large-scale factory production, the incidence rate is reduced, and the production process is easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

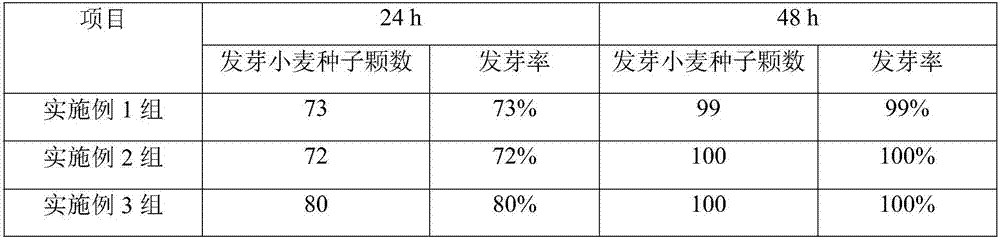

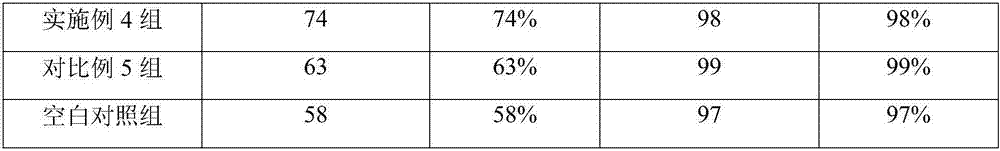

Examples

Embodiment 1

[0036] Embodiment 1 Calcium-containing water-soluble compound fertilizer and its preparation

[0037] Embodiment 1 of the present invention contains calcium water-soluble compound fertilizer, and its preparation process comprises the following steps:

[0038] S1: Take soybean meal, potato, yam and tea meal, grind them, mix them well, add 0.5 times their mass of water, steam them for 20 minutes at a temperature of 121°C, add sodium chloride and an aqueous solution containing 15% molasses after cooling , adjusted to a water content of 55% after mixing to obtain a solid fermentation medium; wherein, in terms of mass ratio, soybean meal: potato: yam: tea meal: aqueous solution containing molasses: sodium chloride is 80:4:15:15 :25:1;

[0039] S2: Transfer the solid fermentation medium described in step S1 to a fermenter, and inoculate the composite fermentation bacteria made by mixing Lactobacillus fermentum, Bacillus subtilis, Bacillus subtilis subsp., Aspergillus oryzae, Asperg...

Embodiment 2

[0043] Embodiment 2 Calcium-containing water-soluble compound fertilizer and its preparation

[0044] Embodiment 2 of the present invention contains calcium water-soluble compound fertilizer, and its preparation process comprises the following steps:

[0045] S1: Take soybean meal, potato, yam and tea meal, grind them, mix them well, add water 1.5 times the mass, steam at 121°C for 30 minutes, add sodium chloride and an aqueous solution containing 25% molasses after cooling , adjusted to a water content of 70% after mixing to obtain a solid fermentation medium; wherein, in terms of mass ratio, soybean meal: potato: yam: tea meal: aqueous solution containing molasses: sodium chloride is 90:8:10:20 :15:1;

[0046] S2: Transfer the solid fermentation medium described in step S1 to a fermenter, and inoculate the composite fermentation bacteria made by mixing Lactobacillus fermentum, Bacillus subtilis, Bacillus subtilis subsp., Aspergillus oryzae, Aspergillus niger and Trichoderma...

Embodiment 3

[0050] Embodiment 3 Calcium-containing water-soluble compound fertilizer and its preparation

[0051] Embodiment 3 of the present invention contains calcium water-soluble compound fertilizer, and its preparation process comprises the following steps:

[0052] S1: Take soybean meal, potato, yam and tea meal, grind them, mix them well, add 0.8 times their mass of water, steam at 121°C for 20 minutes, add sodium chloride and an aqueous solution containing 20% molasses after cooling , adjusted to a water content of 65% after mixing to obtain a solid fermentation medium; wherein, in terms of mass ratio, soybean meal: potato: yam: tea meal: aqueous solution containing molasses: sodium chloride is 88:5:15:15 :20:1;

[0053] S2: Transfer the solid fermentation medium described in step S1 to a fermenter, and inoculate the composite fermentation bacteria made by mixing Lactobacillus fermentum, Bacillus subtilis, Bacillus subtilis subsp., Aspergillus oryzae, Aspergillus niger and Tric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com