All back contact solar battery and preparation method therefor, and assembly and system of solar battery

A solar cell and full back contact technology, applied in the field of solar cells, can solve the problems of high price and high proportion of silver-containing paste, and achieve the effects of saving consumption, reducing metallization area, and reducing repeating units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

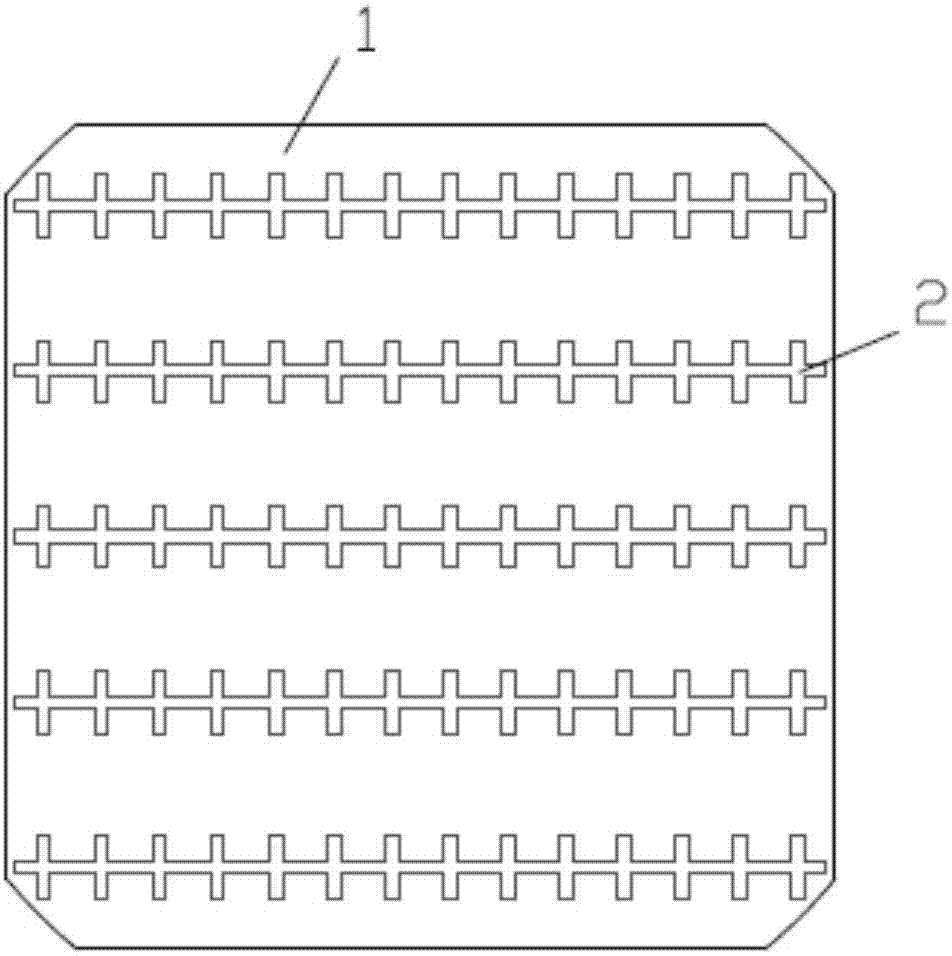

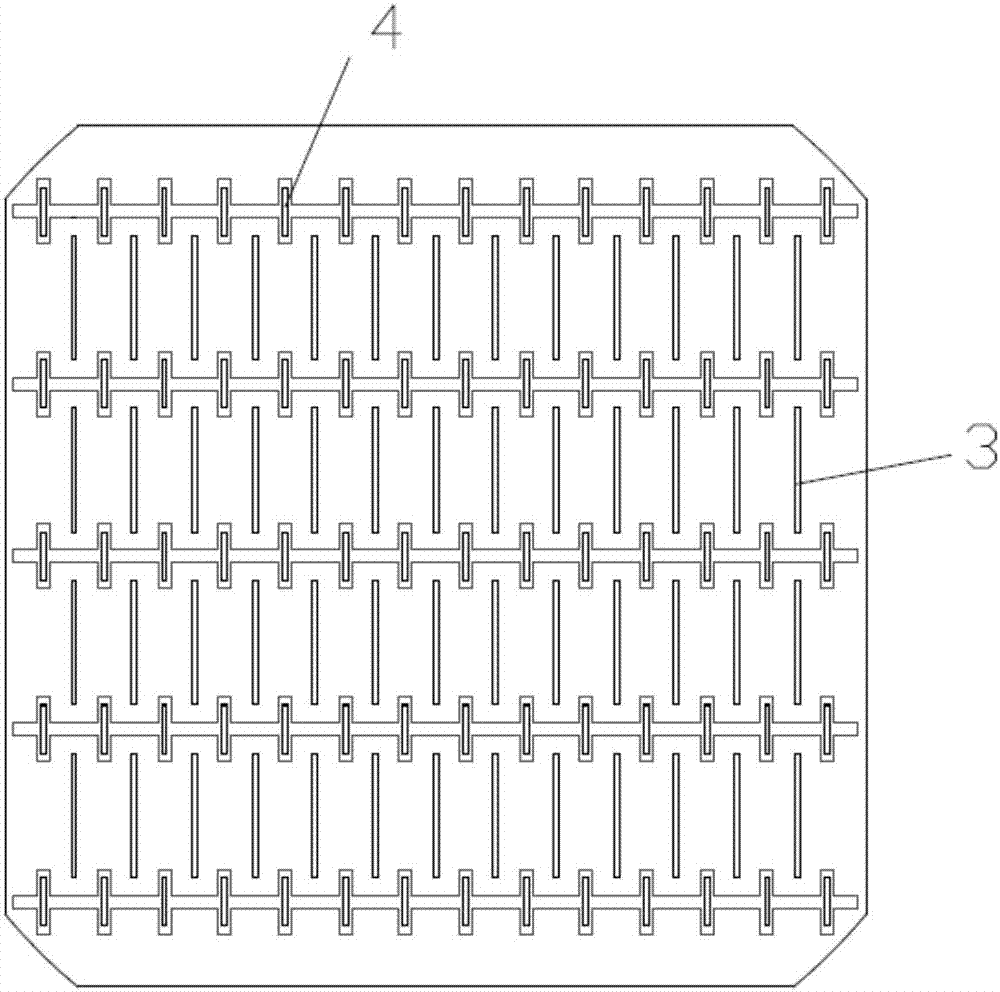

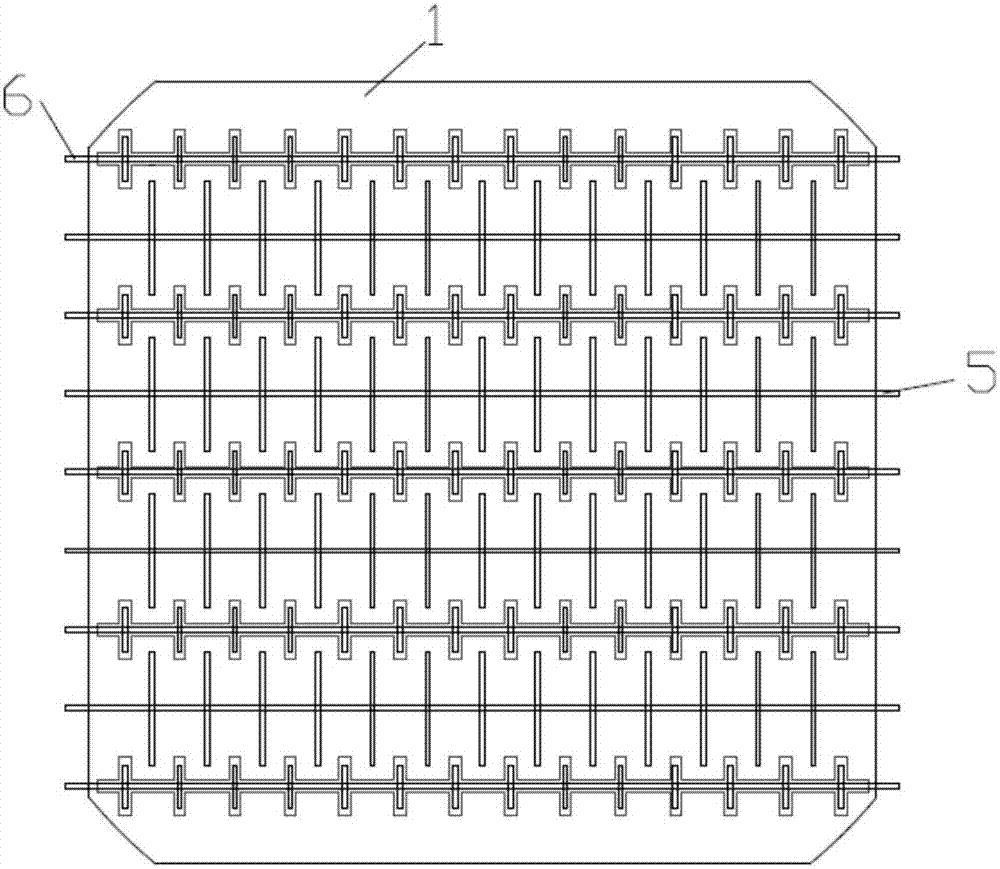

[0035] see Figure 1-4 As shown, the preparation method of a full back contact solar cell of the present embodiment mainly includes the following steps:

[0036] (1), select an N-type solar cell substrate, and perform texturing treatment on the front surface of the N-type solar cell substrate; the resistivity of the N-type solar cell substrate is 0.5~15Ω·cm;

[0037] (2), put the N-type solar cell substrate processed in step (1) into an industrial diffusion furnace to carry out boron diffusion on the textured surface. The boron source is preferably boron tribromide, and the diffusion temperature is 920-1000 ° C. 60-180 minutes; the square resistance after boron diffusion is 40-100Ω / sqr; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com