Dual-ring-chamber alternate heating self-dust-removing intelligent roasting device and roasting method

A calcination device and calcination technology, applied in the direction of lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of red material sensible heat waste, air excess coefficient fuel waste, exhaust heat loss, etc., to achieve fuel saving and waste heat Effective use and reduction of dust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

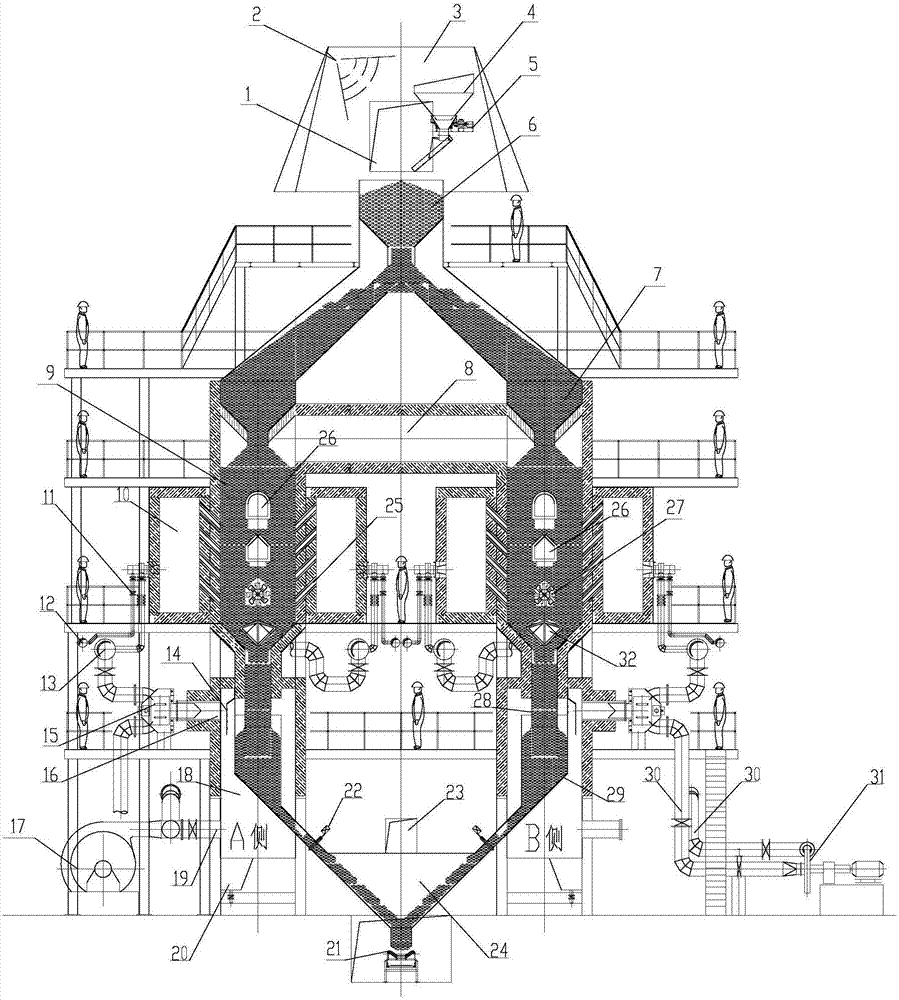

[0055] An intelligent calcination device with double-annular chamber alternately heating and self-filtering dust, including two symmetrically arranged annulus heating calcining fluidized bed systems, and a communication flue 8 is arranged between the two annulus heating calcining fluidized bed systems , an intermediate silo 6 is set at the upper end of the two sets of annular chamber heating calcining fluidized bed systems, and is connected with the feeding system through the intermediate silo 6, and a finished product silo is arranged at the lower end of the two sets of annular chamber heating calcining fluidized bed systems twenty four.

[0056] The annular chamber heating calcining fluidized bed system includes a calcining fluidized bed 9, a calcining bin 7 arranged at the upper end of the calcining fluidized bed 9, a finished product hopper 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com