Method and system for treating coal chemical wastewater in zero-discharge manner

A coal chemical wastewater and treatment method technology, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, aerobic process treatment, etc., can solve the problem of salt separation and difficulty in the evaporation and crystallization of mixed salt hazardous waste, and achieve the realization of crystallized salt The effect of resource utilization and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

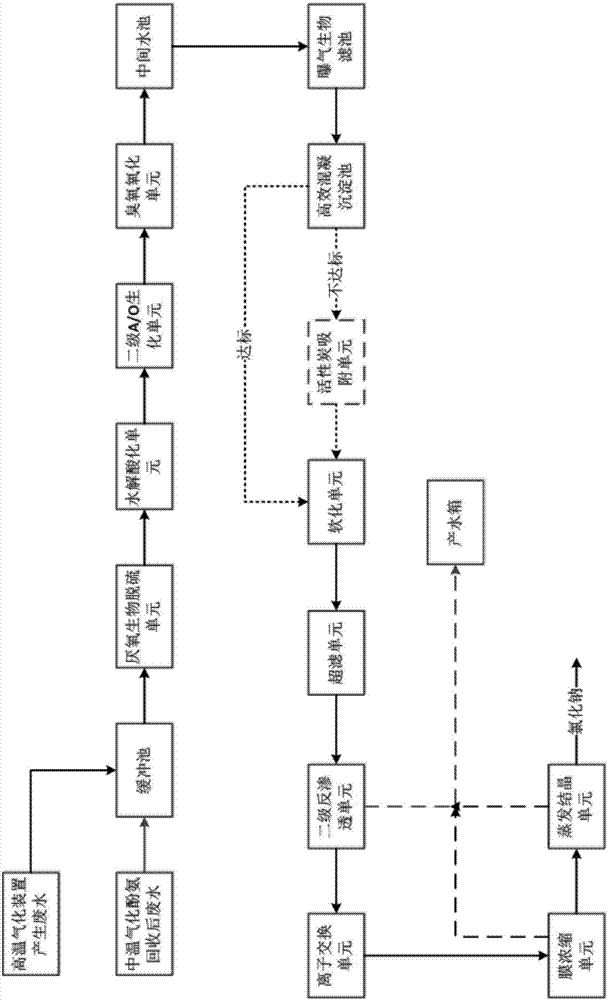

[0031] A zero-discharge treatment method for coal chemical wastewater, including anaerobic biological desulfurization, hydrolytic acidification, secondary A / O biochemical treatment, ozone oxidation, aerated biochemical treatment, coagulation sedimentation, activated carbon adsorption, softening, ultrafiltration, and secondary reverse osmosis , ion exchange, membrane concentration and evaporation crystallization treatment process; coal chemical wastewater is converted into hydrogen sulfide from sulfate in wastewater through anaerobic biological desulfurization, and biodegradability of wastewater through hydrolysis and acidification, secondary A / O biochemistry, ozone oxidation, Aeration biochemical treatment, softening, ultrafiltration, two-stage reverse osmosis, Ca 2+ converted to Na + , to ensure the purity of sodium chloride produced by the evaporative crystallization unit, membrane concentration to produce purified water and evaporative crystallization to produce crystalline...

Embodiment 2

[0047] A zero-discharge treatment system for coal chemical wastewater, including sequentially connected buffer pools, anaerobic biological desulfurization units, hydrolytic acidification units, secondary A / O biochemical units, ozone oxidation units, intermediate pools, biological aerated filters, high-efficiency mixing Condensation sedimentation tank, activated carbon adsorption unit, softening unit, ultrafiltration unit, secondary reverse osmosis unit, ion exchange unit, membrane concentration unit and evaporation crystallization unit; purified water produced by secondary reverse osmosis unit, membrane concentration unit and evaporation crystallization unit Discharge into the product water tank; the solid phase product produced by the evaporation crystallization unit is sodium chloride.

[0048] Wherein, the buffer pool is used to adjust the water volume and uniform water quality of waste water produced by different devices; the middle pool is connected with the ozone oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com