Mesoporous silicon-aluminum molecular sieve adsorbent for VOCs (volatile organic chemicals) treatment and preparation method thereof

A mesoporous silica-alumina and adsorbent technology, which is applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of activated carbon adsorption performance that has a great influence, does not meet safety production requirements, and is prone to fire. Good strength, large pore volume, easy regeneration and reuse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

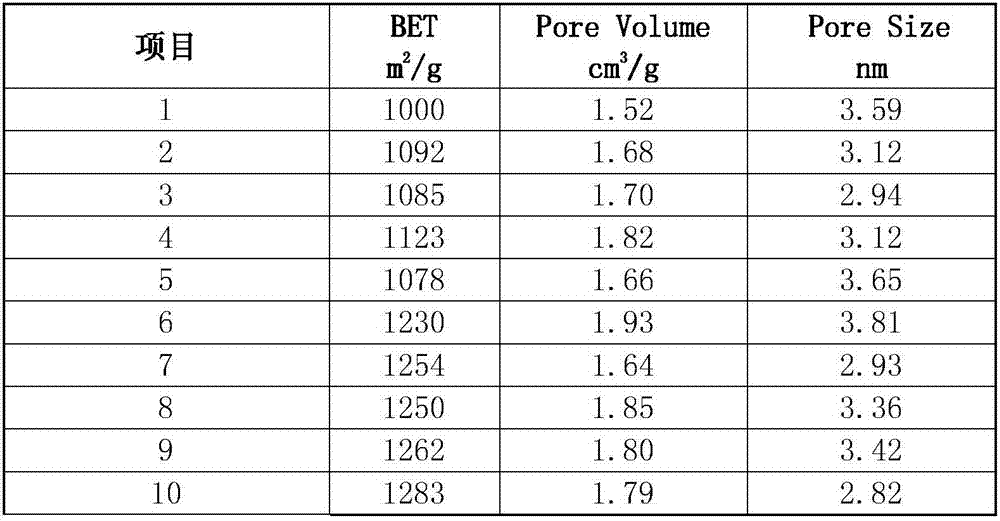

Embodiment 1

[0017] This example is a method for preparing a mesoporous silica-alumina molecular sieve adsorbent for VOCs treatment, comprising the following steps:

[0018] (1) Add 0.39g of aluminum isopropoxide and 0.194g of ferric nitrate to 20mL of ethanol containing 0.2mL of acetylacetone (acac), stir well, and reflux the obtained mixture for 1h;

[0019] (2) Add 10.7 mL of tetraethyl silicate to the mixed solution of step (1);

[0020] (3) Prepare a mixed solution of 8.75gCTAB (cetyltrimethylammonium bromide), 10mL ammonia, and 120mL water;

[0021] (4) Add the mixed solution made in step (2) dropwise to the mixed solution in step (3) in stirring to form a sol; its molar ratio components are: silicon oxide (SiO 2 ): cetyltrimethylammonium bromide (CTAB): water (H 2 O): Ammonia (NH 3 ·H 2 O): aluminum isopropoxide (Al(OPri) 3 ): Iron nitrate (Fe(NO 3 ) 3 ):acetylacetone (acac)=1:0.5:130:2.5:0.04:0.01:1.

[0022] (5) Keep the pH value of the generated sol at 10.5, stir at room ...

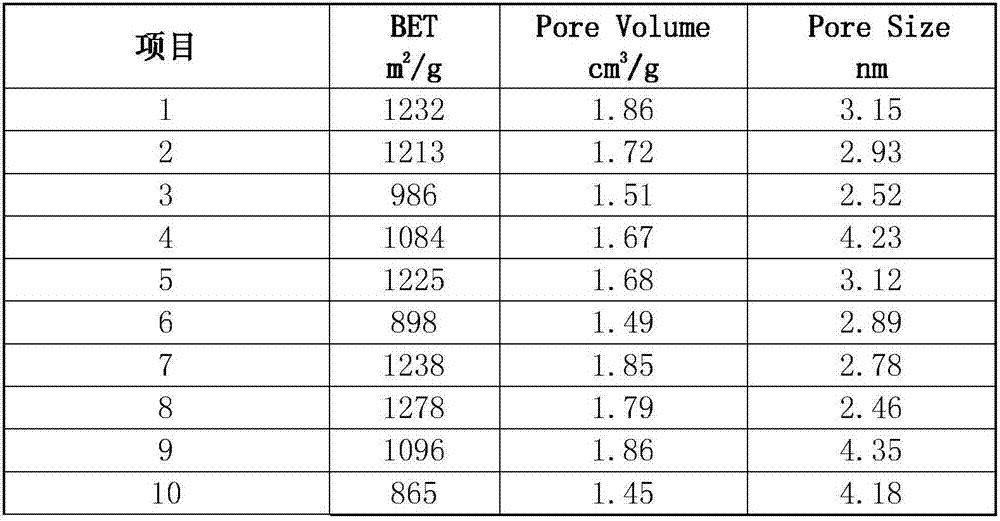

Embodiment 2

[0027] This example is a method for preparing a mesoporous silica-alumina molecular sieve adsorbent for VOCs treatment, comprising the following steps:

[0028] (1) Add 0.39g of aluminum isopropoxide and 0.29g of ferric nitrate to 20mL of isopropanol solution containing 0.4mL of acetylacetone (acac), stir well, and reflux the obtained mixture for 1.5h;

[0029] (2) Add 10 mL of tetraethyl silicate to the mixed solution of step (1);

[0030] (3) Prepare a mixed solution of 8.9gCTAB (cetyltrimethylammonium bromide), 10mL ammonia, and 150mL water;

[0031] (4) Add the mixed solution made in step (2) dropwise to the mixed solution in step (3) in stirring to form a sol; its molar ratio components are: silicon oxide (SiO ): hexadecyl trimethyl Ammonium bromide (CTAB): water (H2O): ammonia water (NH3 H2O): aluminum isopropoxide (Al(OPri)3): iron nitrate (Fe(NO3)3): acetylacetone (acac) = 0.93: 0.5:130:2.5:0.043:0.02:0.8.

[0032] (5) Keep the pH value of the generated sol at 10, sti...

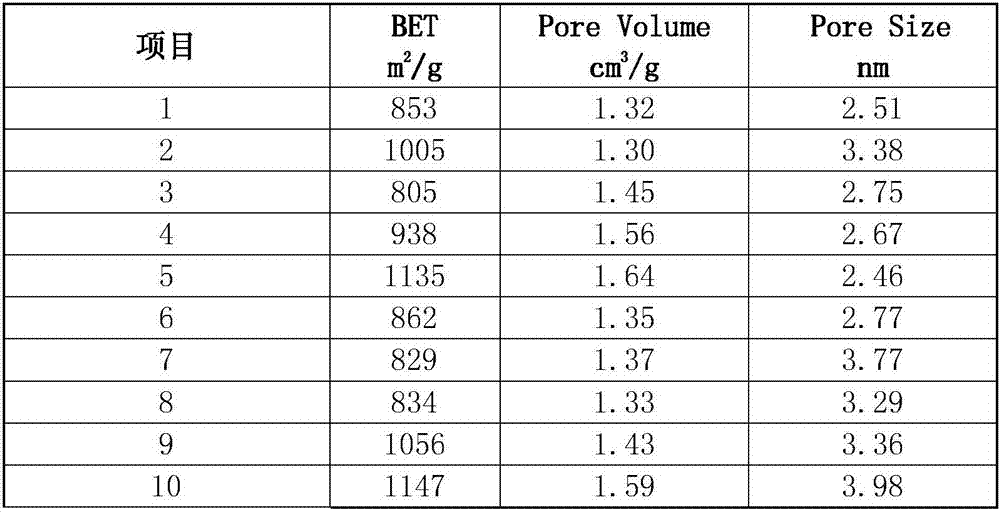

Embodiment 3

[0037] This example is a method for preparing a mesoporous silica-alumina molecular sieve adsorbent for VOCs treatment, comprising the following steps:

[0038] (1) Add 0.39g of aluminum isopropoxide and 0.388g of ferric nitrate to 40mL of isopropanol solution containing 0.8mL of acetylacetone (acac), stir well, and reflux the obtained mixture for 1h;

[0039] (2) Add 10.5 mL of tetraethyl silicate to the mixed solution of step (1);

[0040] (3) Prepare a mixed solution of 8.7gCTAB (cetyltrimethylammonium bromide), 10mL ammonia, and 120mL water;

[0041] (4) Add the mixed solution made in step (2) dropwise to the mixed solution in step (3) in stirring to form a sol; its molar ratio components are: silicon oxide (SiO ): hexadecyl trimethyl Ammonium bromide (CTAB): water (H2O): ammonia water (NH3 H2O): aluminum isopropoxide (Al(OPri)3): iron nitrate (Fe(NO3)3): acetylacetone (acac) = 0.98: 0.5:160:2.5:0.04:0.015:0.4.

[0042] (5) Keep the pH value of the generated sol at 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com