Main chain degradable zinc polyacrylate resin prepared by aid of monomer processes and method and application for main chain degradable zinc polyacrylate resin

A technology of zinc polyacrylate and chain degradation, applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve problems such as marine microplastic pollution, and achieve the effect of solving pollution and solving dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

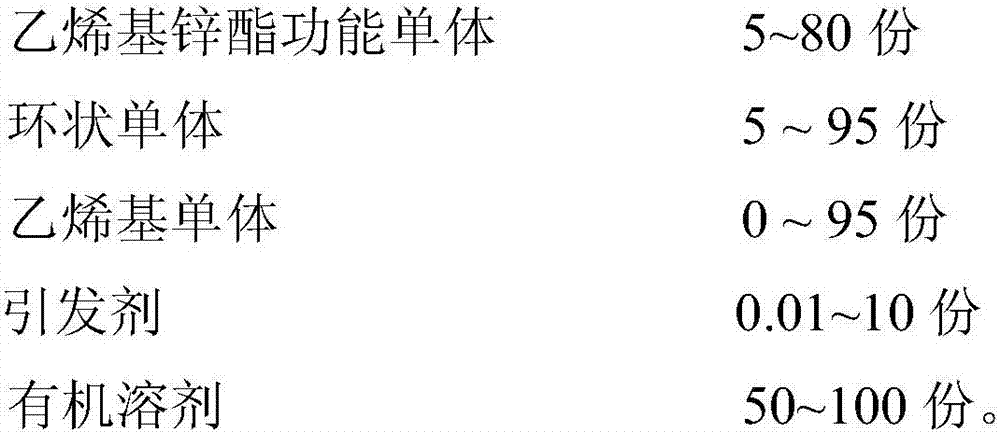

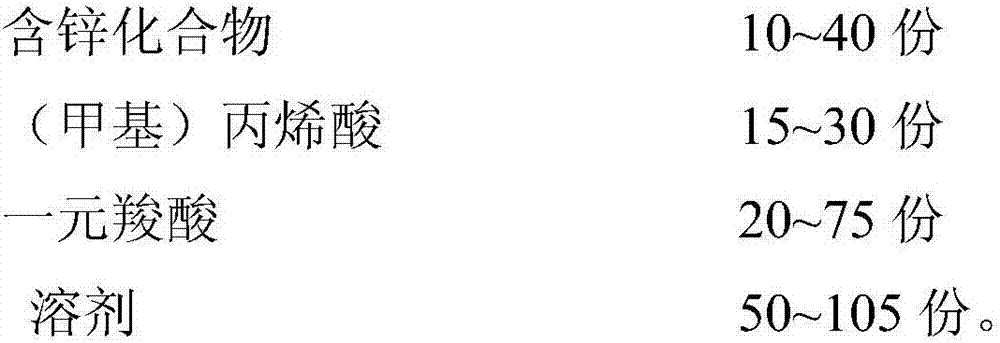

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of main chain degradable polyacrylic acid zinc resin, specifically comprising the following steps:

[0060] (1) Synthesis of vinyl zinc ester functional monomer:

[0061] Add 81.4g of zinc oxide, 200g of propylene glycol methyl ether and 40g of xylene to the reaction vessel, heat to 65°C, add dropwise a mixture of 72.1g of acrylic acid, 86.1g of methacrylic acid and 10g of deionized water in 3 hours, after the addition is complete, Insulated and reacted for 2 hours to obtain a colorless and transparent vinyl zinc ester functional monomer solution;

[0062] (2) Synthesis of zinc polyacrylate resin:

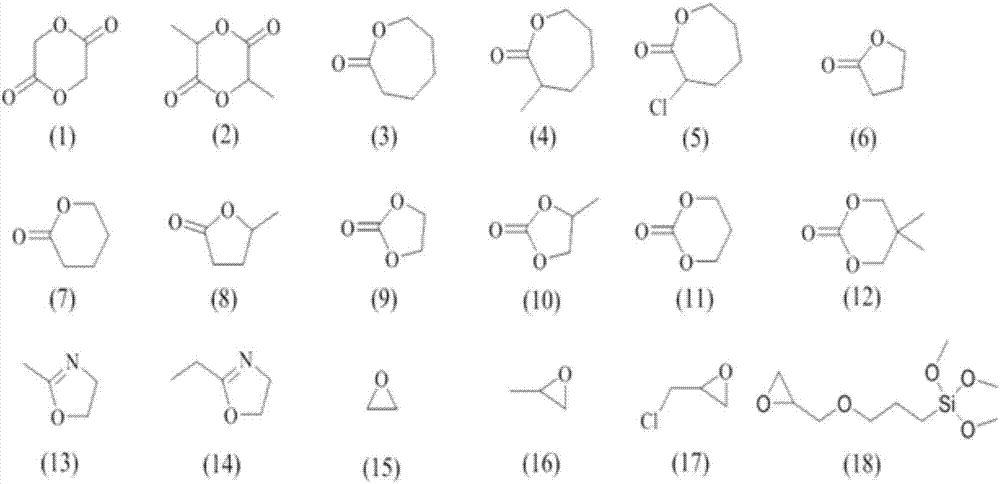

[0063] Under the condition of stirring, add 500g of xylene, 100g of propylene glycol methyl ether and 24g of ethyl acrylate to the reaction vessel, raise the temperature to 90°C under a nitrogen atmosphere, add dropwise 44g of 2-methylene-1,3-bis Oxycycloheptane, 44g-2-methoxyethyl methacrylate, 176g methyl methacrylate, 396g ethyl acrylate, 449.6g ste...

Embodiment 2

[0066] A preparation method of main chain degradable polyacrylic acid zinc resin, specifically comprising the following steps:

[0067] (1) Synthesis of vinyl zinc ester functional monomer:

[0068] Add 81.4g of zinc oxide, 400g of xylene and 100g of isopropanol to the reaction vessel, heat to 80°C, add dropwise a mixture of 72.1g of acrylic acid and 340g of naphthenic acid (acid number 165) at a constant rate, and drop it in 3 hours , after the dropwise addition was completed, the insulation reaction was carried out for 2 hours to obtain a brown transparent vinyl zinc ester functional monomer solution;

[0069] (2) Synthesis of zinc polyacrylate resin:

[0070] Under the condition of stirring, add 350g of xylene and 100g of methyl isobutyl ketone into the reaction vessel, raise the temperature to 95°C under a nitrogen atmosphere, and add 100g of caprolactone, 100g of methyl acrylate, and 100g of butyl acrylate dropwise at a constant speed for 4 hours. , 200g cyclohexyl meth...

Embodiment 3

[0073] A preparation method of main chain degradable polyacrylic acid zinc resin, specifically comprising the following steps:

[0074] (1) Synthesis of vinyl zinc ester functional monomer:

[0075] Add 99.4g of zinc hydroxide, 400g of toluene and 74g of isobutanol to the reaction vessel, and heat it to 75°C, dropwise add a mixture of 72.1g of acrylic acid and 302.5g of abietic acid at a constant speed for 3 hours, after the dropwise addition, keep the temperature for 2 hours for reaction , to obtain a yellow transparent vinyl zinc ester functional monomer solution;

[0076] (2) Synthesis of zinc polyacrylate resin:

[0077] Under the condition of stirring, add 500g of xylene and 400g of butyl acetate into the reaction vessel, raise the temperature to 100°C under a nitrogen atmosphere, and add 150g of lactide, 584g of isooctyl acrylate, and 292g of ethyl methacrylate dropwise at a constant speed for 4 hours. Ester, 948g of vinyl zinc ester functional monomer solution in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com