Lithium ion battery positive electrode material and preparation method and application thereof

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficulty in improving electronic conductivity and poor electronic conductivity, and achieve good application prospects, high tap density, and excellent Effects of Conductivity and Electrochemical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

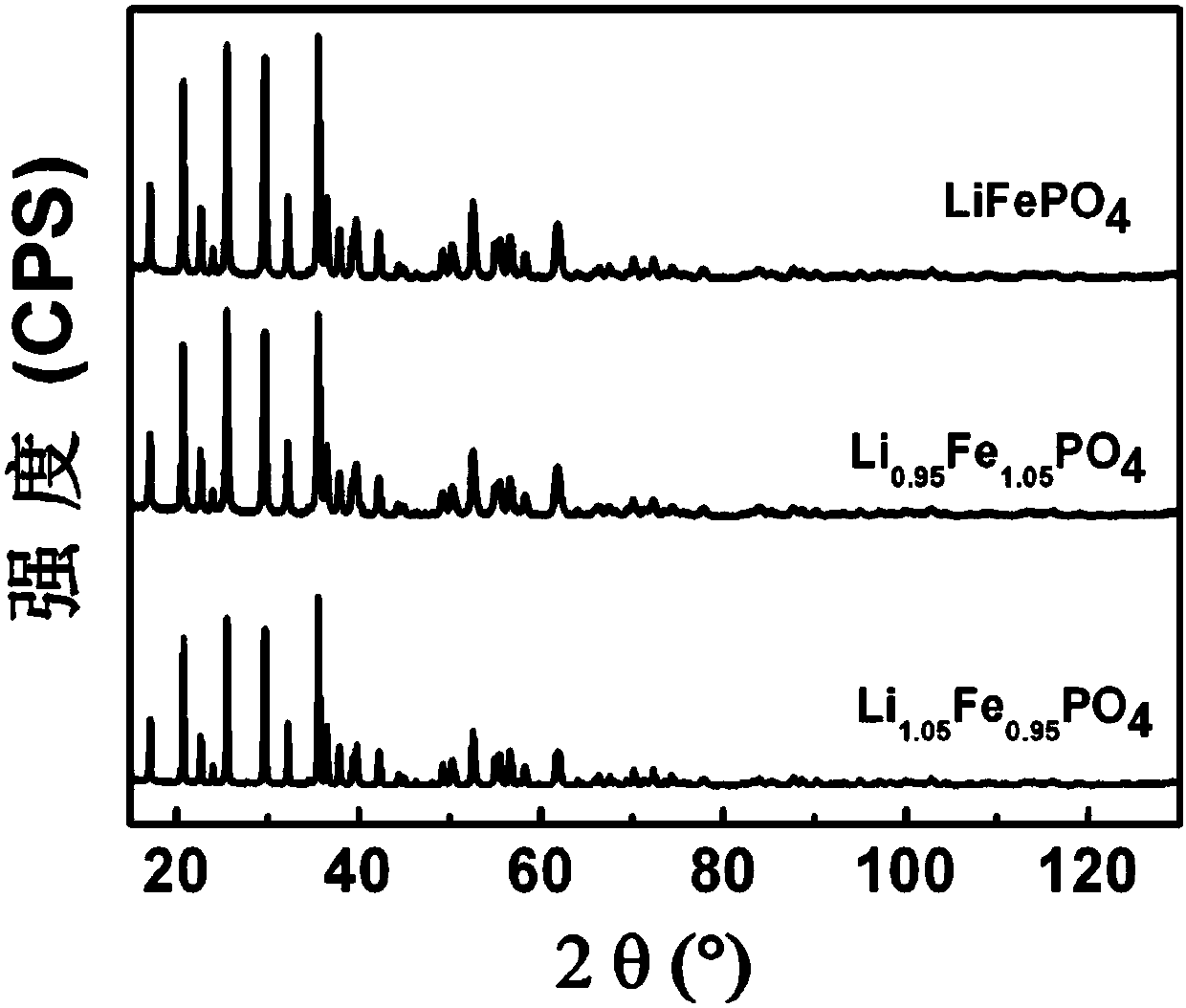

[0057] Design Li according to composition 1+x Fe 1-x PO 4 (x=0.02) to prepare Li with excess lithium and insufficient iron 1.02 Fe 0.98 PO 4 material.

[0058] Add 0.0024mol of glycine to 100ml of deionized water, add 0.0048mol of glucose after the glycine is dissolved; stir at room temperature until completely dissolved into a transparent solution; add 0.02448mol of lithium acetate and 0.024mol of phosphoric acid to the above transparent solution After stirring until it is uniform and transparent, add 0.02352mol of ferric sulfate and continue stirring for 6 hours at room temperature; stir and evaporate the mixture at a constant temperature of 80°C to obtain a precursor; preheat and decompose the precursor at 150°C for 5 hours, The preheated decomposition product is ground; the ground product is heat-treated at 750° C. under a nitrogen atmosphere for 4 hours, and cooled to obtain a lithium iron phosphate lithium ion battery cathode material.

Embodiment 2

[0062] Design Li according to composition 1+x Fe 1-x PO 4 (x=0.05), prepare Li with excess lithium and insufficient iron 1.05 Fe 0.95 PO 4 material.

[0063] Add 0.0024mol of citric acid to 100ml of deionized water, add 0.0048mol of sucrose after the citric acid is dissolved; stir at room temperature until completely dissolved into a transparent solution; add 0.0126mol of lithium carbonate and 0.024mol of dihydrogen phosphate Add the above transparent solution, stir until it is uniform and transparent, then add 0.0228mol of ferric nitrate and stir at room temperature for 5 hours; the mixture is stirred and evaporated to dryness at a constant temperature of 80°C to obtain the precursor; the precursor is pretreated at 200°C After thermal decomposition for 4 hours, the preheated decomposition product is ground; the ground product is heat-treated at 650° C. under an argon atmosphere for 6 hours, and cooled to obtain a lithium iron phosphate lithium ion battery cathode material.

[0064...

Embodiment 3

[0067] Design Li according to composition 1+x Fe 1-x PO 4 (x=0.07) to prepare Li with excess lithium and insufficient iron 1.07 Fe 0.93 PO 4 material.

[0068] Add 0.0024mol of acrylic acid to 100ml of deionized water, add 0.0048mol of fructose after the acrylic acid is dissolved; stir at room temperature until completely dissolved into a transparent solution; add 0.02568mol of lithium nitrate and 0.024mol of diammonium hydrogen phosphate to the above In the transparent solution, stir until it is uniform and transparent, then add 0.02232 mol of ferric chloride and continue to stir for 3 hours at room temperature; the mixture is stirred and evaporated to dryness at a constant temperature of 80°C to obtain the precursor; the precursor is pretreated at 280°C After thermal decomposition for 2.5 hours, the preheated decomposition product is ground; the ground product is heat-treated at 500° C. for 8 hours under a helium atmosphere, and the positive electrode material for lithium iron p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com