Preparation and application of 3-nitrotyrosine molecularly imprinted electrochemical transducer

A nitrotyrosine and molecular imprinting technology, applied in the field of chemical analysis, can solve the problems of slow electron transfer speed and response, affecting the application of molecular imprinting technology, difficult to control the thickness of the imprinting film, etc., achieving convenient on-site detection and fast detection speed. , Sensitive and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

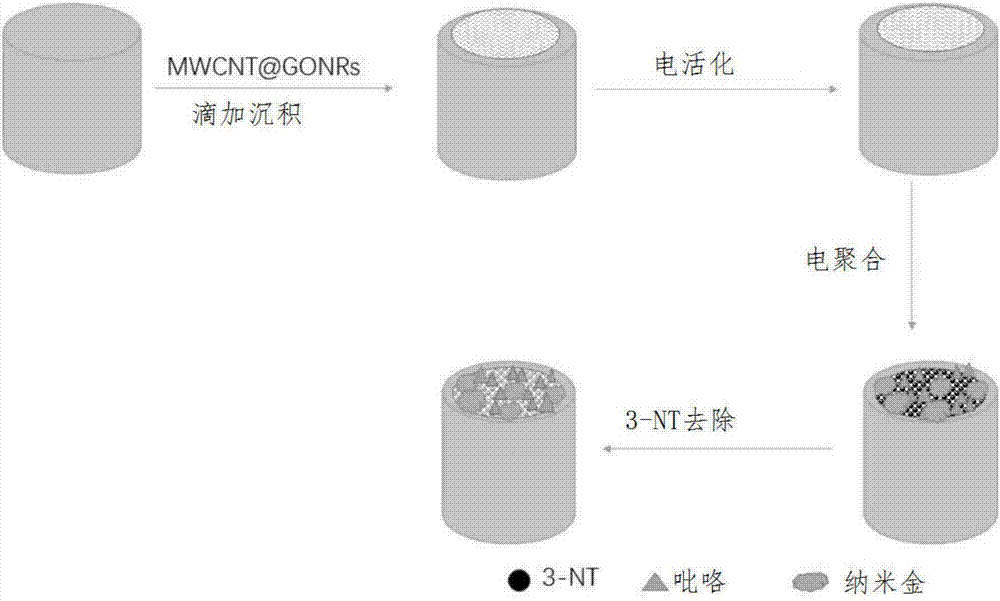

[0040] The preparation of embodiment 1 electrode

[0041] 1) Pretreatment of the glassy carbon electrode: the glassy carbon electrode is sequentially treated with 0.5 μm and 0.05 μm Al 2 o 3 The powder is polished on suede, rinsed with ultrapure water and ultrasonically cleaned in 50% nitric acid solution, ethanol and water for 5 minutes, and then the electrode is scanned in 5mmol / L potassium ferricyanide until a reversible cycle is obtained. Volt-ampere peak;

[0042] 2) Preparation of multi-walled carbon-coupled graphene oxide nanobelt nanomaterials: 120mg MWCNT dispersed in 40mLH 2 SO 4 / H 3 PO 4 (9:1 molar ratio) solution, stirred at room temperature for 1h. Then slowly add 600mg KMnO to the above solution 4 Then, under the condition of 65°C, heat in a water bath for 2h. Finally, 400 mL of ice water (containing 5 mL of 30% H 2 o 2 ) to terminate the reaction. Filtrate with a polytetrafluoroethylene membrane, wash with water, wash with ethanol, and finally dry in...

Embodiment 2

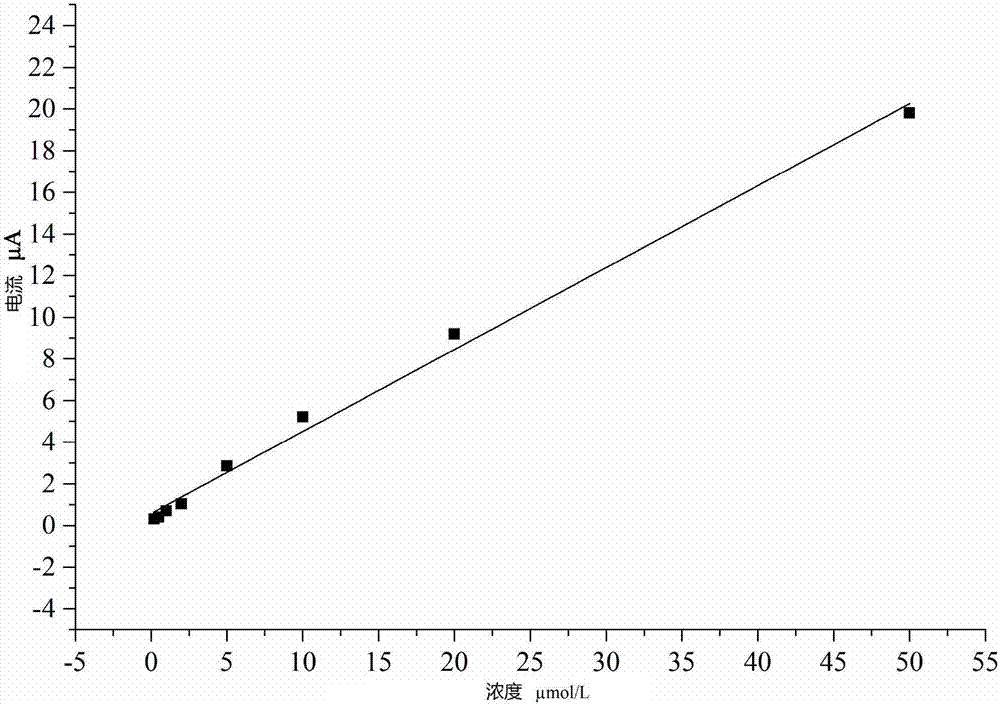

[0046] The drawing of embodiment 2 working curve and the mensuration of limit of detection

[0047] The responsivity of 3-nitrotyrosine molecularly imprinted electrochemical sensor was tested by square wave stripping voltammetry, and the linear range and detection limit were determined. The 3-nitrotyrosine molecularly imprinted electrochemical sensor was immersed in different 3-nitrotyrosine standards, and then square-wave stripping voltammetry was performed. With Ag / AgCl as the reference electrode, Pt electrode as the counter electrode, molecular imprinted electrochemical sensor as the working electrode, connected to the electrochemical workstation, in different concentrations of 3-nitrotyrosine, the scanning potential is 1.02V, Detect the relationship between the change of the electrical signal before and after the elution of the electrochemical sensor and the adsorption of template molecules and the concentration of 3-nitrotyrosine, and draw a working curve, such as figure...

Embodiment 3

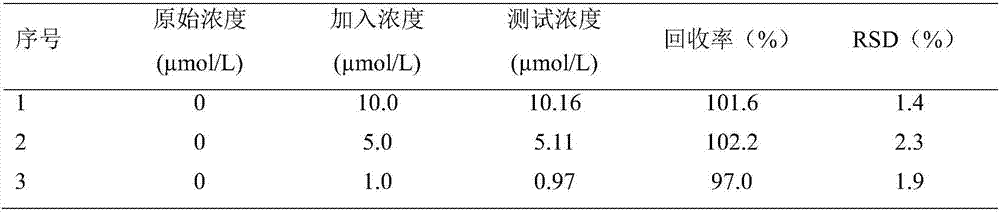

[0050] Embodiment 3 Regeneration, reproducibility and interference experiment of modified electrode

[0051] Five 3-nitrotyrosine molecularly imprinted electrochemical sensors were prepared under the conditions described in Example 1, using the same 3-nitrotyrosine molecularly imprinted electrochemical sensor pair 5.0×10 -5 mol / L 3-nitrotyrosine for 5 consecutive measurements, after each measurement, the electrode surface must be cleaned with deionized water. The relative standard deviation of the calculated current response value is 3.2% (n=5), indicating that the molecularly imprinted electrode has good reproducibility. The combination of the template molecule and the "hole" on the imprinted membrane is a reversible process, and the 3-nitrotyrosine molecularly imprinted electrochemical sensor can be used repeatedly. In addition, using the modified electrode stored for three months in the dark to measure the same concentration of 3-nitrotyrosine, the oxidation peak current r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com