Negative electrode material used for sodium ion battery and preparation method and application of negative electrode material

A sodium-ion battery and negative electrode material technology, which is applied in the field of materials science, can solve the problems of battery capacity attenuation, restricting development, etc., and achieve the effects of low preparation cost, low performance requirements, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 2.25g of nickel oxide and 1.488g of boric acid evenly through dry ball milling, heat up to 650°C at a rate of 3°C / min in a tube furnace under air atmosphere and keep it at a constant temperature for 5h, then cool naturally to room temperature, and use After washing with hot water at 100°C, dry at 100°C for 10 hours to obtain the product nickel borate.

Embodiment 2

[0027] Mix 8.73g of nickel nitrate hexahydrate and 1.488g of boric acid uniformly by ball milling, heat up to 850°C at a rate of 3°C / min in a tube furnace under air atmosphere and keep it at a constant temperature for 4h, then cool naturally to room temperature, and use After washing with hot water at 70°C, dry at 120°C for 12 hours to obtain the product nickel borate.

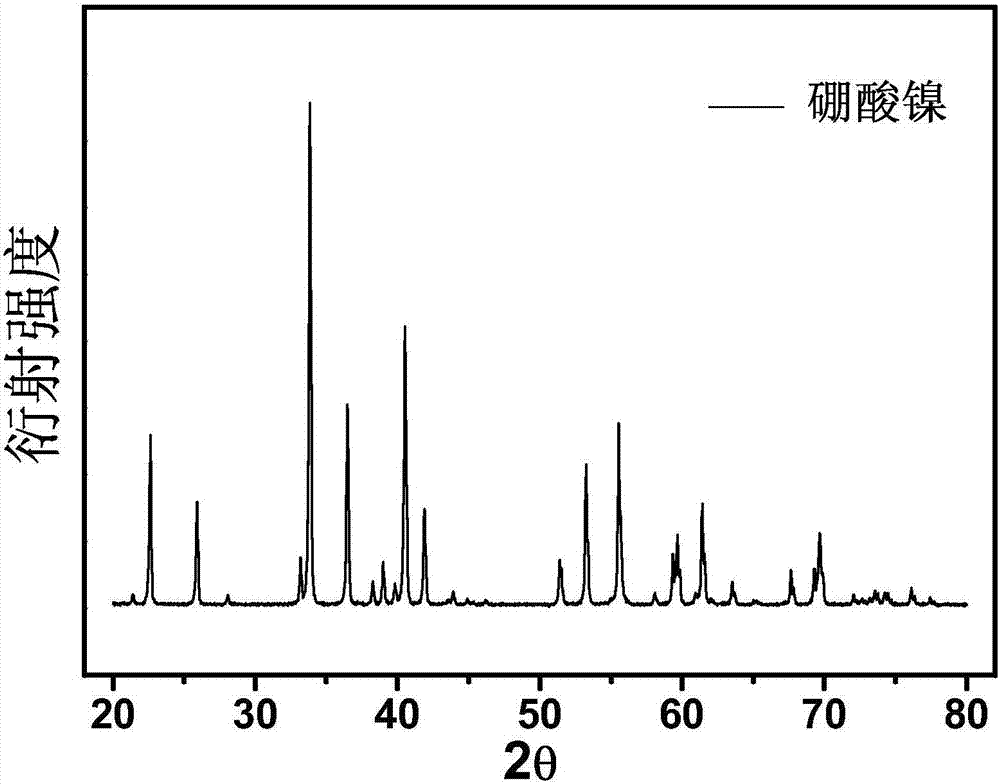

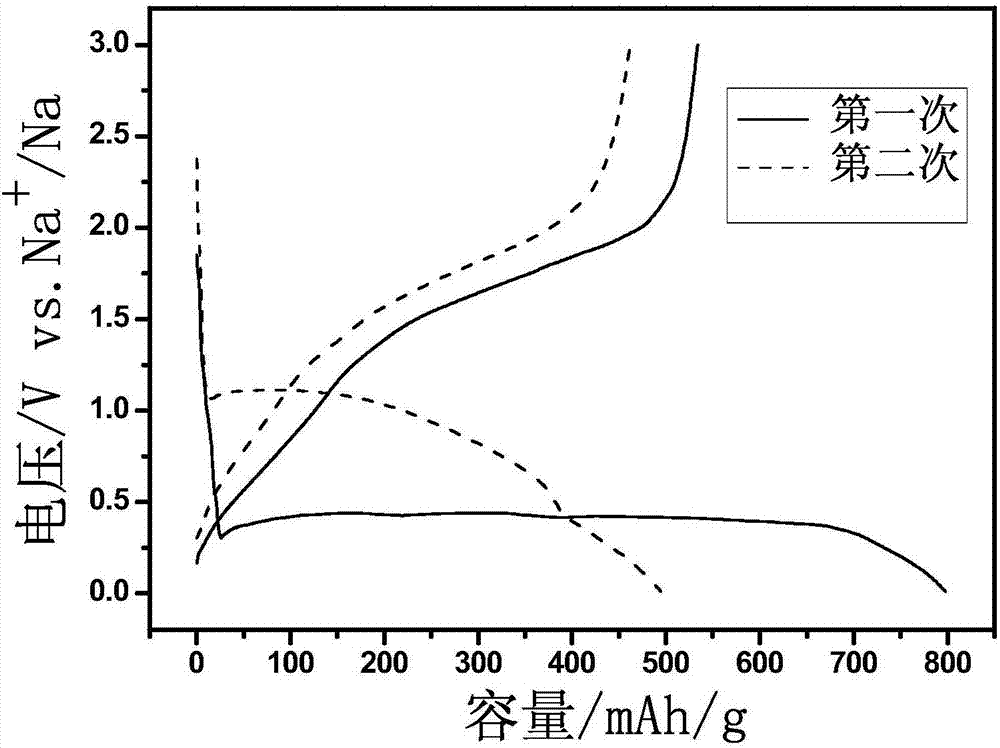

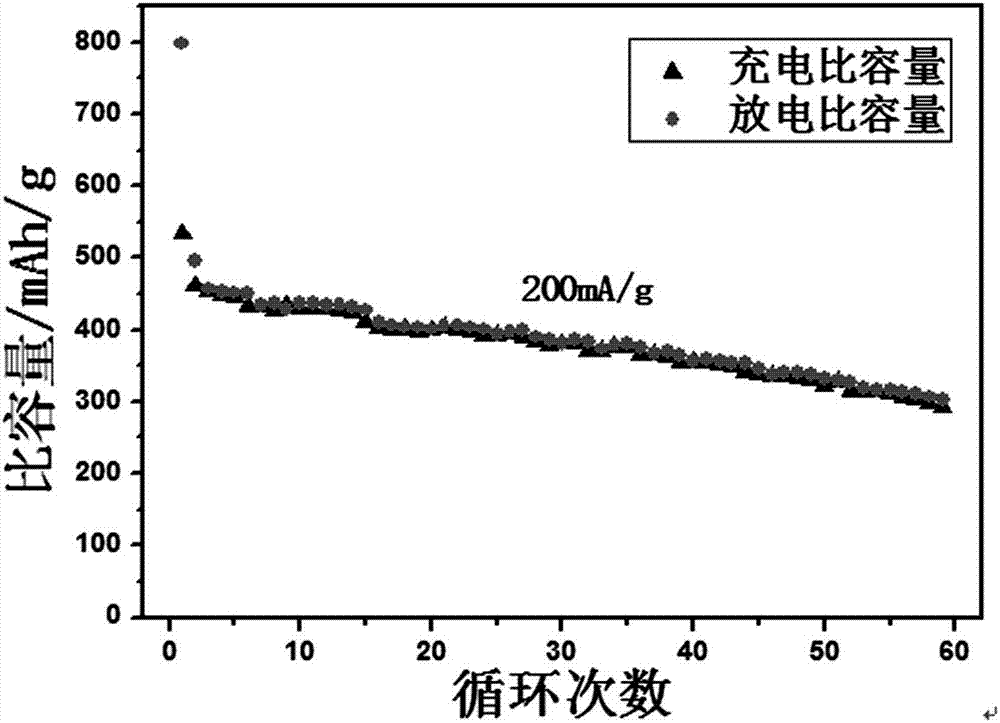

[0028] figure 1 It is the XRD pattern of nickel borate material, the peak position of the XRD pattern of the material can completely match the peak position and peak intensity on the standard card (JCPDS.No. 75-1809), indicating that the composition of the prepared material is Ni 3 B 2 o 6 , and no impurity exists. figure 2 It is the first and second charge and discharge curves of nickel borate material, as shown in the figure, within the charge and discharge voltage range of 0.01-3.0V, there is an obvious discharge platform in the first discharge process, while in the The same platform did not appear in ...

Embodiment 3

[0030] Mix 4.41g of nickel oxalate and 1.488g of boric acid uniformly by ball milling, heat up to 750°C at a rate of 5°C / min under air atmosphere and keep the temperature for 10h, then naturally cool to room temperature, wash with 80°C hot water, and Dry at 100°C for 8 hours to obtain the product nickel borate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com