Special slow-controlled-release fertilizer for strawberry and preparation method of the special slow-controlled-release fertilizer

A technology for controlled-release fertilizers and strawberries, applied in the agricultural field, can solve the problems of reduced utilization rate of fertilizers, deterioration of soil environment, aggravation of strawberry diseases, etc., and achieves the effects of reducing fertilizer loss, wide source of raw materials, and disease prevention and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

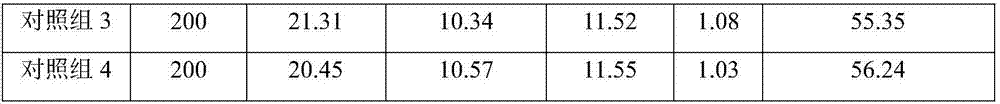

Examples

Embodiment 1

[0023] Components: 25 parts by weight of urea, 15 parts of heavy superphosphate, 21 parts of potassium magnesium sulfate, 25 parts of decomposed organic active fertilizer, 5 parts of white cardamom, 3 parts of woody fragrance, 3 parts of humic acid, 6 parts of polymerized amino acid , 2.5 parts of medium and trace elements, 0.75 parts of metalaxyl, 0.75 parts of mancozeb, 0.5 parts of bentonite, and 1 part of polyolefin resin. The decomposed organic active fertilizer is obtained by fermenting 60 parts of earthworm manure and 40 parts of vinegar grains by EM bacteria for 35 days according to the weight ratio; the mass ratio of zinc sulfate, borax, iron sulfate and ammonium molybdate in the medium and trace elements is 1:2:0.3: 0.5.

[0024] Mix and granulate nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, decomposed organic active fertilizer, humic acid, polymerized amino acid, medium and trace elements, and fungicides, and apply the coating agent to the fertil...

Embodiment 2

[0026] Components: 30 parts by weight of ammonium nitrate phosphate fertilizer, 22 parts of calcium metaphosphate, 14 parts of potassium sulfate, 20 parts of decomposed organic active fertilizer, 8 parts of white cardamom, 5 parts of woody fragrance, 5 parts of humic acid, 3 parts of polymerized amino acid , 5 parts of medium and trace elements, 0.5 part of metalaxyl, 0.5 part of mancozeb, 0.5 part of bentonite, and 0.5 part of polyolefin resin. The decomposed organic active fertilizer is obtained by fermenting 70 parts of earthworm manure and 30 parts of vinegar grains by EM bacteria for 35 days according to the weight ratio; the mass ratio of zinc sulfate, borax, iron sulfate and ammonium molybdate among the medium and trace elements is 2:1:1: 0.1.

[0027] Mix and granulate nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, decomposed organic active fertilizer, humic acid, polymerized amino acid, medium and trace elements, and fungicides, and apply the coating...

Embodiment 3

[0029] Components: 27 parts of urea, 18 parts of monoammonium sulfate, 16 parts of potassium sulfate, 22 parts of decomposed organic active fertilizer, 6 parts of white cardamom, 4 parts of woody fragrance, 4 parts of humic acid, 5 parts of polymerized amino acid, 4 parts of medium and trace elements 1 part, 0.5 part of metalaxyl, 1 part of mancozeb, 1 part of bentonite, and 1 part of polyolefin resin. The decomposed organic active fertilizer is obtained by fermenting 60 parts of earthworm manure and 40 parts of vinegar grains by EM bacteria for 35 days according to the weight ratio; the mass ratio of zinc sulfate, borax, iron sulfate and ammonium molybdate among the medium and trace elements is 1:1:1: 0.5.

[0030] Mix and granulate nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, decomposed organic active fertilizer, humic acid, polymerized amino acid, medium and trace elements, and fungicides, and apply the coating agent to the fertilizer granules through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com