Modified hydrotalcite and solar battery back panel

A technology for solar cells and modified water, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the aging resistance of coatings, coating cracks, coating residues, etc., and achieve improved hydrolysis resistance and adhesion The effect of good performance and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

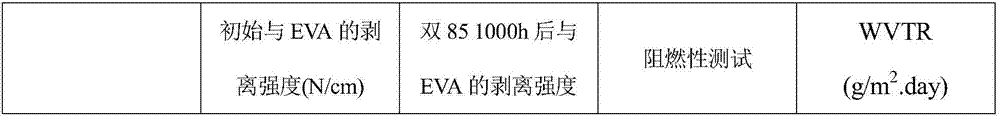

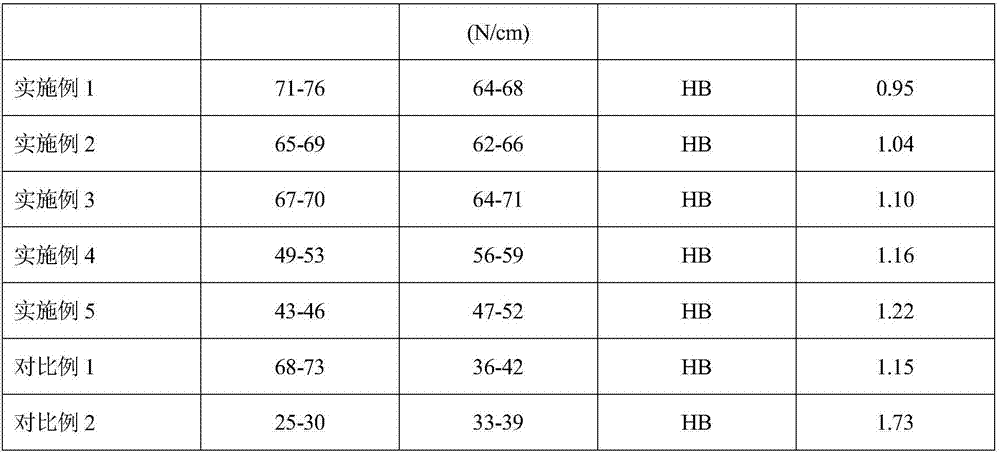

Examples

preparation example Construction

[0031] The preparation process of modified hydrotalcite is:

[0032] Dissolve a certain amount of modifier in ethanol, pour it into a three-necked flask, then dissolve Mg(NO3)2·6H2O in deionized water to obtain A solution (2mol·L-1), and Al(NO3)3· 9H2O was dissolved in deionized water to obtain B solution (3mol·L-1). Under magnetic stirring and N2 protection, solution A and solution B were slowly added dropwise to the three-necked flask respectively, and 2mol L-1NaOH solution was added dropwise at the same time, so that the pH of the reaction system was maintained at 10, reacted at room temperature for 48h, and the product was filtered , and dried in an oven after washing to obtain modified hydrotalcite.

[0033] The reagents for preparing hydrotalcite are all known commercially available products.

[0034] The preparation process of fluorine-containing coatings:

[0035] Add fluorocarbon resin, PUA resin, ethyl acetate, modified hydrotalcite (self-made) into a wide-mouth c...

Embodiment 1

[0048] Take 75.8mL of ethylene glycol methacrylate acetoacetate and dissolve it in 50mL of ethanol. As for the three-necked flask, add 25.8g of Mg(NO 3 ) 2 ·6H 2 O was dissolved in 40mL deionized water to obtain A solution (2mol L -1 ), 66.17g Al(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to obtain B solution (3mol L -1 ). Under magnetic stirring and N 2 Under protection, slowly drop 37.5mL of solution A and 12.5mL of solution B into the three-necked flask, and at the same time add 2mol·L -1 NaOH solution to keep the pH of the reaction system at 10, and react at room temperature for 48 hours. The product was filtered, washed and dried in an oven to obtain ethylene glycol methacrylate acetoacetate modified hydrotalcite.

[0049] Add 200g fluorocarbon resin GK 570 (manufactured by Daikin Fluorochemical Co., Ltd., OH value 60mgKOH / g, solid content 60%), 36g PUA resin UV-2032 (Dongguan Inoue Chemical Technology Co., Ltd.), 195g acetic acid in a wide mouth contai...

Embodiment 2

[0052] Take 75.8mL of diacetone acrylamide and dissolve it in 50mL of ethanol. As for the three-necked flask, add 25.8g of Mg(NO 3 ) 2 ·6H 2 O was dissolved in 40mL deionized water to obtain A solution (2mol L -1 ), 66.17g Al(NO 3 ) 3 9H 2 O was dissolved in 30mL deionized water to obtain B solution (3mol L -1 ). Under magnetic stirring and N 2 Under protection, slowly drop 35mL of solution A and 23mL of solution B into the three-necked flask, and at the same time add 2mol·L -1 NaOH solution to keep the pH of the reaction system at 10, and react at room temperature for 48 hours. The product was filtered, washed and dried in an oven to obtain diacetoneacrylamide-modified hydrotalcite.

[0053] In a wide mouth container, add 200g fluorocarbon resin ETERFLON4101 (manufactured by Changxing Chemical Industry Co., Ltd., OH value is 56mgKOH / g, solid content 60%), 24g PUA resin JZ-302 (Nanjing Jiazhong Chemical Technology Co., Ltd.), 156g butyl acetate, 67g diacetone acrylami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com