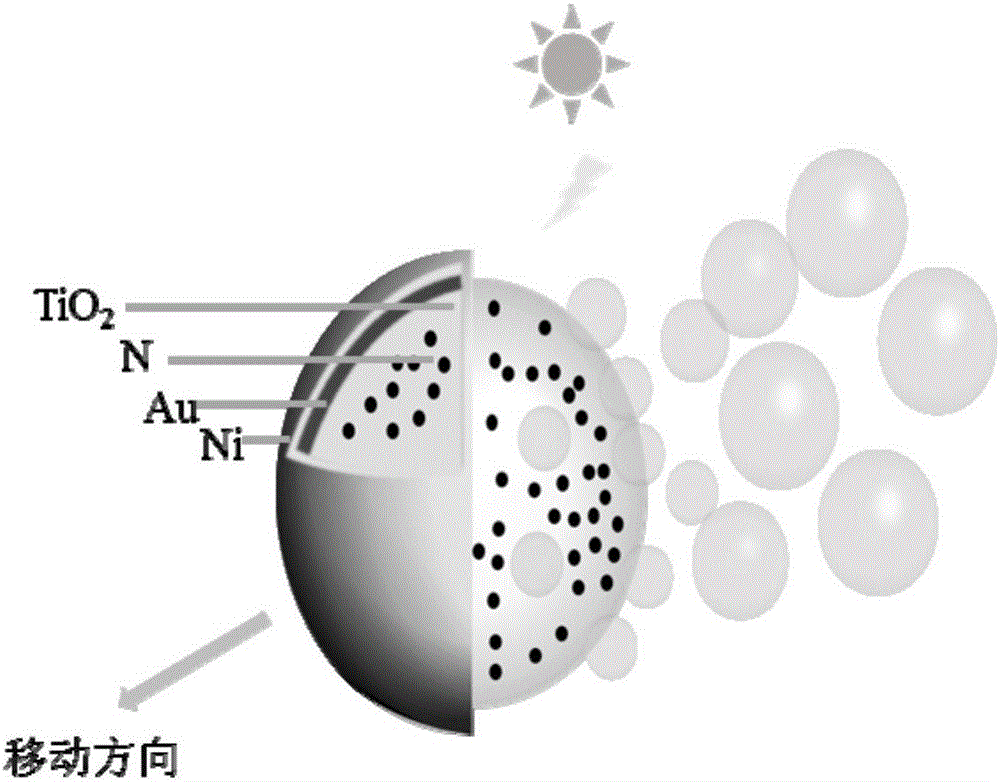

Manufacturing method of light-driven micro-robot for environmental restoration

A technology of micro-robots and environmental restoration, applied in the field of engineering, can solve problems such as short lifespan, and achieve the effects of low cost, wide application prospects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) First, disperse 3 g of pre-purchased polystyrene microspheres (1 μm in diameter) into a 0.5 mol / L aqueous solution of cetyltrimethylammonium bromide, sonicate for 10 minutes, and take them out to dry. The purpose of ultrasound is to activate the surface of the polystyrene microspheres.

[0028] Drop 12mL of 1.0mol / L titanium tetrachloride aqueous solution into 20mL of 5wt% ammonia water to produce a precipitate, wash the resulting precipitate with deionized water after centrifugation to pH=7, and then add excess mass to the precipitate The hydrogen peroxide with a concentration of 30% until the solution turns into an orange-yellow transparent liquid is a precursor with photocatalytic particles.

[0029] Next, add the polystyrene microspheres dried in step (1) into the orange transparent liquid, and react in a 250mL three-neck flask at 100°C for 8h. The product is washed, filtered, and vacuum-dried to obtain core-shell particles with photocatalytic properties. Spher...

Embodiment 2

[0034] (1) First, 6 g of pre-purchased polystyrene microspheres (4 μm in diameter) were dispersed in 100 mL of ethanol to obtain a solution containing polystyrene microspheres.

[0035] 100mL of absolute ethanol solution containing 1g of tetrabutyl titanate (that is, the precursor with photocatalytic particles) was added dropwise to the solution containing polystyrene microspheres to obtain a mixed solution;

[0036] Secondly, according to the molar ratio n (Fe) :n (Ti) Weigh ferric nitrate at a ratio of 1:100 and add it to the mixed solution, stir and react at 100°C for 2 hours, then add 5g of concentrated ammonia water (mass concentration is 25% to 28%), continue stirring for 3 hours, filter, wash with alcohol, and vacuum dry . The obtained product was calcined at 550 °C for 2 h to obtain iron-doped titanium dioxide hollow microspheres (Fe-TiO 2 ), which are spherical particles with a core-shell structure with photocatalytic particles. The ammoniacal liquor in this step ...

Embodiment 3

[0043] (1) Disperse 6g of the mixture of glucose, protein and cellulose in 35mL of deionized water and stir until evenly dispersed, then transfer to a 50mL reaction kettle, react at 185°C for 13h, and the product is centrifuged with absolute ethanol for several times and then vacuum Dry to obtain carbon microspheres.

[0044] Next, disperse the obtained carbon microspheres in 100 mL of an aqueous solution containing zinc acetate (0.5 mol / L) and titanium tetrachloride (0.1 mol / L) and sonicate until uniformly dispersed, then age for 24 h, and the product is washed with deionized water several times Vacuum drying after centrifugal cleaning; then the dried product was calcined at 500° C. for 1 h to obtain titanium atom-doped zinc oxide hollow microspheres (Ti-ZnO) with a mass fraction of titanium atom doping of 1.2%.

[0045] (2) First, place the Ti-ZnO obtained in the above step (1) on the surface of the aluminum foil, and fix it horizontally on the sample stage of the electron b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com