A preparation method of light-driven micro-robots for environmental restoration

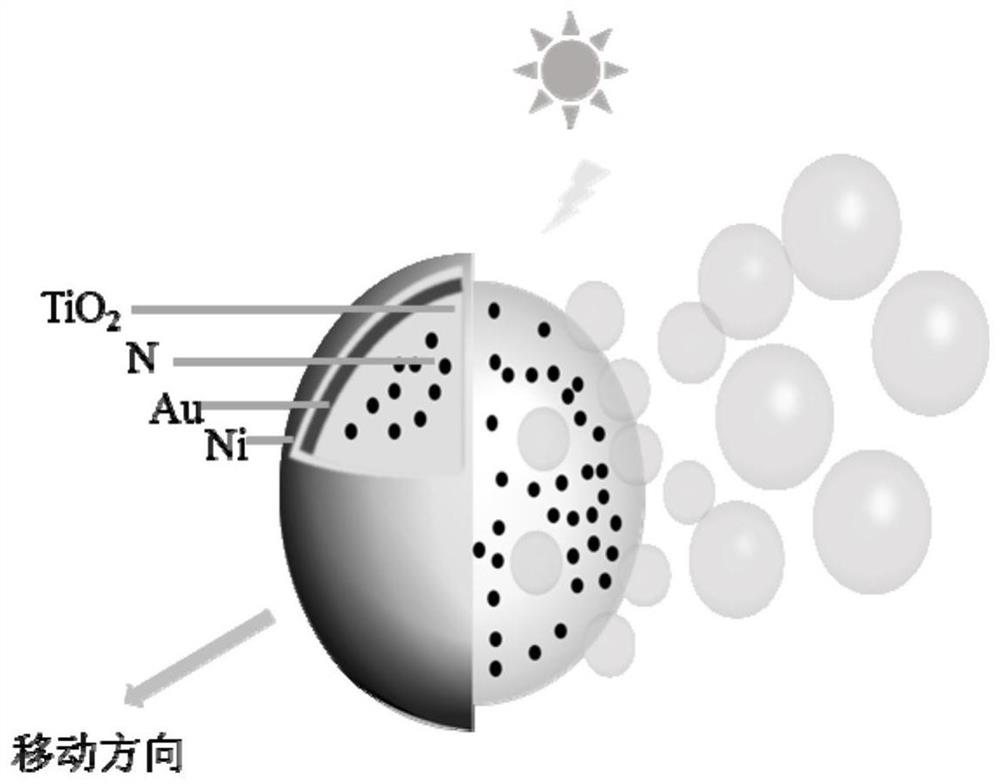

A micro-robot and environmental restoration technology, applied in the field of engineering, can solve problems such as short life, achieve low cost, improve operating speed and environmental restoration efficiency, and improve visible light responsiveness and catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) First, disperse 3 g of pre-purchased polystyrene microspheres (1 μm in diameter) into a 0.5 mol / L aqueous solution of cetyltrimethylammonium bromide, sonicate for 10 minutes, and take them out to dry. The purpose of ultrasound is to activate the surface of the polystyrene microspheres.

[0028] Drop 12mL of 1.0mol / L titanium tetrachloride aqueous solution into 20mL of 5wt% ammonia water to produce a precipitate, wash the resulting precipitate with deionized water after centrifugation to pH=7, and then add excess mass to the precipitate The hydrogen peroxide with a concentration of 30% until the solution turns into an orange-yellow transparent liquid is a precursor with photocatalytic particles.

[0029] Next, add the polystyrene microspheres dried in step (1) into the orange transparent liquid, and react in a 250mL three-neck flask at 100°C for 8h. The product is washed, filtered, and vacuum-dried to obtain core-shell particles with photocatalytic properties. Spher...

Embodiment 2

[0034] (1) First, 6 g of pre-purchased polystyrene microspheres (4 μm in diameter) were dispersed in 100 mL of ethanol to obtain a solution containing polystyrene microspheres.

[0035] 100mL of absolute ethanol solution containing 1g of tetrabutyl titanate (that is, the precursor with photocatalytic particles) was added dropwise to the solution containing polystyrene microspheres to obtain a mixed solution;

[0036] Secondly, according to the molar ratio n (Fe) :n (Ti) Weigh ferric nitrate at a ratio of 1:100 and add it to the mixed solution, stir and react at 100°C for 2 hours, then add 5g of concentrated ammonia water (mass concentration is 25% to 28%), continue stirring for 3 hours, filter, wash with alcohol, and vacuum dry . The obtained product was calcined at 550 °C for 2 h to obtain iron-doped titanium dioxide hollow microspheres (Fe-TiO 2 ), which are spherical particles with a core-shell structure with photocatalytic particles. The ammoniacal liquor in this step ...

Embodiment 3

[0043] (1) Disperse 6g of the mixture of glucose, protein and cellulose in 35mL of deionized water and stir until evenly dispersed, then transfer to a 50mL reaction kettle, react at 185°C for 13h, and the product is centrifuged with absolute ethanol for several times and then vacuum Dry to obtain carbon microspheres.

[0044] Next, disperse the obtained carbon microspheres in 100 mL of an aqueous solution containing zinc acetate (0.5 mol / L) and titanium tetrachloride (0.1 mol / L) and sonicate until uniformly dispersed, then age for 24 h, and the product is washed with deionized water several times Vacuum drying after centrifugal cleaning; then the dried product was calcined at 500° C. for 1 h to obtain titanium atom-doped zinc oxide hollow microspheres (Ti-ZnO) with a mass fraction of titanium atom doping of 1.2%.

[0045] (2) First, place the Ti-ZnO obtained in the above step (1) on the surface of the aluminum foil, and fix it horizontally on the sample stage of the electron b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com