Palladium/magnesium-titanium dioxide gas-induced dimming film and its preparation

A technology of titanium dioxide and dimming film, which is applied in the field of palladium/magnesium-titanium dioxide gas-induced dimming film and preparation, can solve the problems of unfavorable commercial application, poor durability and high preparation cost, and achieves low cost, good durability and recovery. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

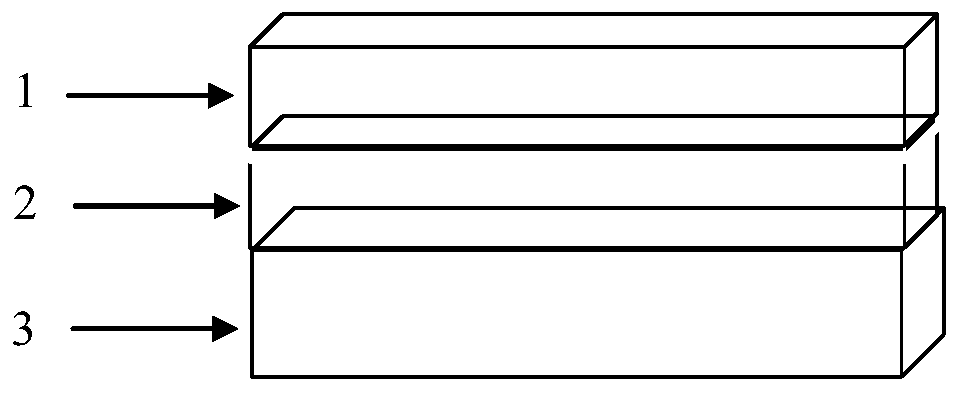

[0037] This embodiment provides a method for preparing a palladium / magnesium-titanium dioxide gas-induced dimming film, comprising the following steps:

[0038] (1) A titanium dioxide target is made of titanium dioxide powder with a purity (mass fraction) of 99.99%, and a copper back plate is added. The same titanium dioxide target is used in the following examples 2 to 6;

[0039] (2) Soak the quartz glass sheet with the prepared cleaning solution for 10 minutes, rinse the quartz glass sheet with deionized water for 1 minute; put the cleaned quartz glass substrate into the magnetron sputtering reaction chamber, and turn on the vacuum system for vacuuming , until the background vacuum is 3×10 -6 Torr;

[0040] (3) Heating the substrate so that the temperature of the substrate is 20-25°C, injecting the working gas, and maintaining 5×10 -3 After the pressure of Torr is stable, turn on the power of the magnesium and titanium dioxide targets, pre-sputter for 5 minutes to clean t...

Embodiment 2

[0045] This embodiment provides a method for preparing a palladium / magnesium-titanium dioxide gas-induced dimming film, comprising the following steps:

[0046] (1) Soak the quartz glass sheet with the prepared cleaning solution for 10 minutes, rinse the quartz glass sheet with deionized water for 1 minute; put the cleaned quartz glass substrate into the magnetron sputtering reaction chamber, and turn on the vacuum system for vacuuming , until the background vacuum is 3×10 -6 Torr;

[0047] (2) Heating the substrate so that the temperature of the substrate is 20-25°C, injecting working gas, and maintaining 5×10 -3 After the pressure of Torr is stabilized, turn on the power of the magnesium and titanium dioxide targets, pre-sputter for 5 minutes to clean the targets, set the sputtering power of the magnesium and titanium dioxide targets to 180W and 400W respectively, and the sputtering time to 50s, start Deposit magnesium-titanium dioxide film with a film thickness of 56nm; ...

Embodiment 3

[0050] This embodiment provides a method for preparing a palladium / magnesium-titanium dioxide gas-induced dimming film, comprising the following steps:

[0051] (1) Soak the quartz glass sheet with the prepared cleaning solution for 10 minutes, rinse the quartz glass sheet with deionized water for 1 minute; put the cleaned quartz glass substrate into the magnetron sputtering reaction chamber, and turn on the vacuum system for vacuuming , until the background vacuum is 3×10 -6 Torr;

[0052] (2) Heating the substrate so that the temperature of the substrate is 20-25°C, injecting working gas, and maintaining 5×10 -3 After the pressure of Torr is stabilized, turn on the power of magnesium and titanium dioxide targets, pre-sputter for 5 minutes to clean the targets, set the sputtering power of magnesium and titanium dioxide targets to 80W and 300W respectively, and the sputtering time to 180s, start Depositing a magnesium-titanium dioxide thin film with a film thickness of 100nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com