A method for enzymatically and efficiently preparing corneal acellular matrix tissue engineering scaffold

A technology of tissue engineering scaffold and acellular matrix, which is applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of destroying telopeptides, low toughness and tension, and difficulty in shaping, so as to achieve good biocompatibility and promote reconstruction , the effect of good biological function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Extraction and purification of Myroilysin

[0047] 1. the preparation method of elastase Myroilysin specifically comprises the steps:

[0048] Preparation of crude enzyme solution of Myroilysin

[0049] According to the method established in the laboratory, the deep-sea psychrotrophic bacteria Myroides profundi D25 was inoculated in the liquid seed medium, and cultured with shaking at 15°C for 2 days to activate the strain.

[0050] The bacteria species activated in the above steps were inoculated in the liquid fermentation medium at an inoculum size of 1% (v / v), and cultured with shaking at 15° C. and 180 rpm for 72 hours to obtain a fermentation broth.

[0051] According to the method already established in the laboratory, the fermented broth prepared above was subjected to ammonium sulfate precipitation, resuspension, dialysis, and DEAE anion exchange to prepare Myroilysin crude enzyme liquid.

[0052] 2. Preparation of Myroilysin Concentrated Enzyme ...

Embodiment 2

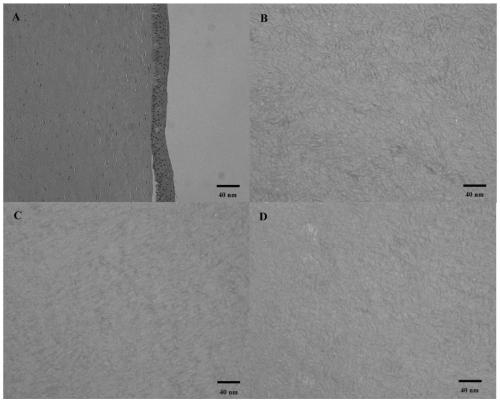

[0054] Example 2: Preparation method of corneal decellularized scaffold

[0055] The preparation method of porcine corneal decellularized scaffold specifically comprises the following steps:

[0056] Take fresh pig eyeballs, and fix the pig eyeballs on the chopping board, with the pig cornea facing straight up. Use a negative pressure trephine to make a circular incision with a depth of about 200 μm in the center of the pig cornea, peel off the corneal lamellar layer with a tunnel knife and a blade, and place it in normal saline;

[0057] The concentrated Myroilysin solution was diluted to 200 μg / ml with 50 mM Tris-HCl (pH 9.0) with a glycerol content of 20% of the total volume. Place the corneal lamina in the Myroilysin solution, and treat it at 37°C for 16 hours with a rotation speed of 80rpm to prepare porcine corneal decellularized scaffolds;

[0058] Porcine corneal decellularized scaffolds were rinsed with distilled water, and then washed with physiological saline for ...

Embodiment 3

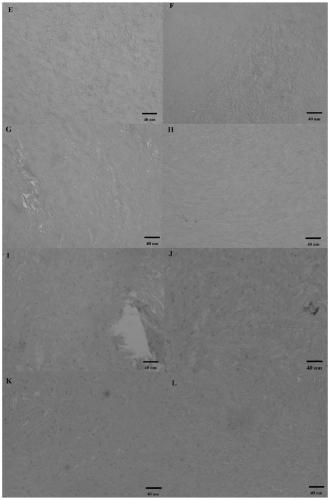

[0062] Example 3: Physicochemical and Physiological Properties Detection of Acellular Corneal Scaffold

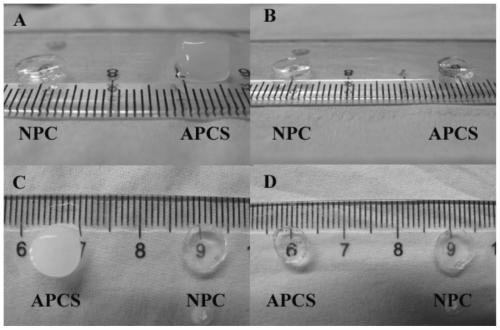

[0063] 1. Transparency detection of porcine corneal decellularized scaffolds

[0064] Place porcine corneal decellularized scaffolds and natural porcine corneas on a 96-well plate, and detect the transparency changes of porcine corneal decellularized scaffolds in the wavelength range of 300-800nm at an interval of 10nm;

[0065] 2. Stability testing of porcine corneal decellularized scaffolds

[0066] The buffer for type Ⅰ collagenase contains 5 mM Ca 2+ Dissolve 500 μg / ml type Ⅰ collagenase in the type Ⅰ collagenase solution in PBS buffer solution to obtain type Ⅰ collagenase solution.

[0067] The porcine corneal decellularized scaffolds and natural porcine cornea were soaked in type Ⅰ collagenase solution and type Ⅰ collagenase buffer respectively, and the residual mass of porcine corneal decellularized scaffolds and natural porcine cornea was measured with a microba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com