Preparation method of fluffy porous nitrogen-doped oxygen reduction catalyst

A nitrogen-doped carbon and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of general performance of oxygen reduction catalysts, various raw materials, and inability to meet the requirements of oxygen reduction catalysts, etc. , to achieve excellent resistance to methanol and carbon monoxide poisoning, increase specific surface area and pore volume, and excellent oxygen reduction catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

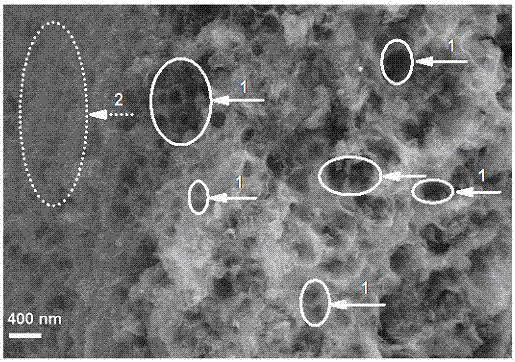

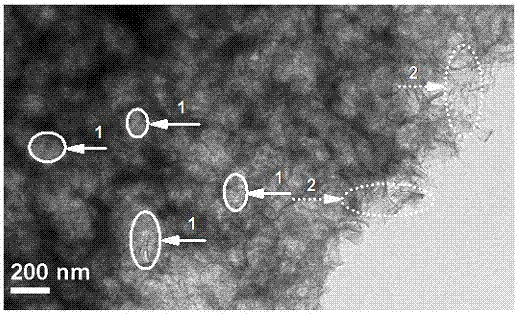

[0026] (1) Put 1.1g of glucose, 3.3g of zinc chloride, 1.1g of basic magnesium carbonate pentahydrate and 0.297g of urea in a glass mortar and grind for 10 minutes to mix them well to obtain material A1;

[0027] (2) Transfer material A1 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, the temperature was raised from room temperature to 300°C for 60 minutes, kept at 300°C for 120 minutes, and then heated at 10°C / min. The heating rate of min was raised to 900°C for 120 minutes, and then the temperature was naturally lowered to room temperature to obtain material B1;

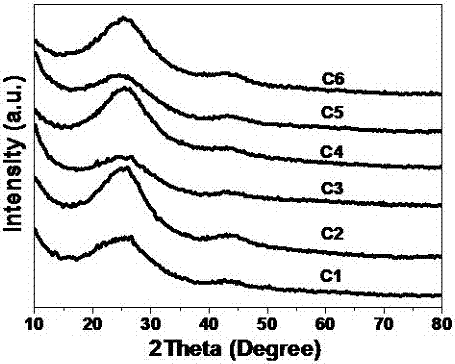

[0028] (3) Transfer material B1 to a 100mL beaker and add 80mL of hydrochloric acid solution with a molar concentration of 2mol / L to soak for 18h, then wash with high-purity water until the filtrate is neutral, and then dry in a blast drying oven at 40°C for 12h to obtain fluffy and porous Nitrogen-doped carbon-oxygen reduction catalyst C1.

Embodiment 2

[0030] (1) Put 1.1g of glucose, 3.3g of zinc chloride, 1.1g of basic magnesium carbonate pentahydrate and 0.594g of urea in a glass mortar and grind for 10 minutes to mix them well to obtain material A2;

[0031] (2) Transfer material A2 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, the temperature was raised from room temperature to 300°C for 60 minutes, kept at 300°C for 120 minutes, and then heated at 10°C / min. The heating rate of min was raised to 900°C for 120 minutes, and then the temperature was naturally lowered to room temperature to obtain material B2;

[0032] (3) Transfer material B2 to a 100mL beaker and add 80mL of hydrochloric acid solution with a molar concentration of 2mol / L to soak for 18h, then wash with high-purity water until the filtrate is neutral, and then dry in a blast drying oven at 40°C for 12h to obtain fluffy and porous Nitrogen-doped carbon-oxygen reduction catalyst C2.

Embodiment 3

[0034] (1) Put 1.1g of glucose, 3.3g of zinc chloride, 1.1g of basic magnesium carbonate pentahydrate and 1.16g of urea in a glass mortar and grind for 10 minutes to mix them well to obtain material A3;

[0035] (2) Transfer material A3 to a porcelain boat and place it in a tube furnace. Under the protection of nitrogen gas with a flow rate of 100mL / min, the temperature was raised from room temperature to 300°C for 60 minutes, kept at 300°C for 120 minutes, and then heated at 10°C / min. The heating rate of min was raised to 900°C for 120 minutes, and then the temperature was naturally lowered to room temperature to obtain material B3;

[0036] (3) Transfer material B3 to a 100mL beaker and add 80mL of hydrochloric acid solution with a molar concentration of 2mol / L to soak for 18h, then wash with high-purity water until the filtrate is neutral, and then dry in a blast drying oven at 40°C for 24h to obtain fluffy and porous Nitrogen-doped carbon-oxygen reduction catalyst C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com