Styrenic-based polymer coated silver nanoparticle-sulfonated polyester composite powders and methods of making same

A technology of silver nanoparticles and composite powder, applied in the field of composites, can solve problems such as incomplete disinfection of surfaces and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

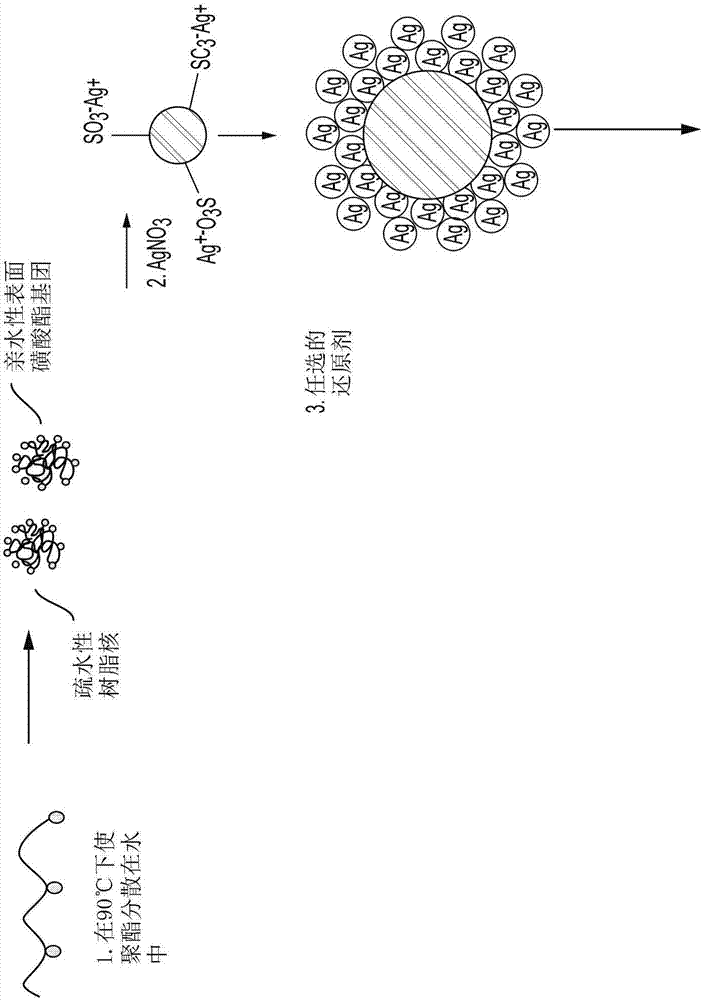

Method used

Image

Examples

example 1

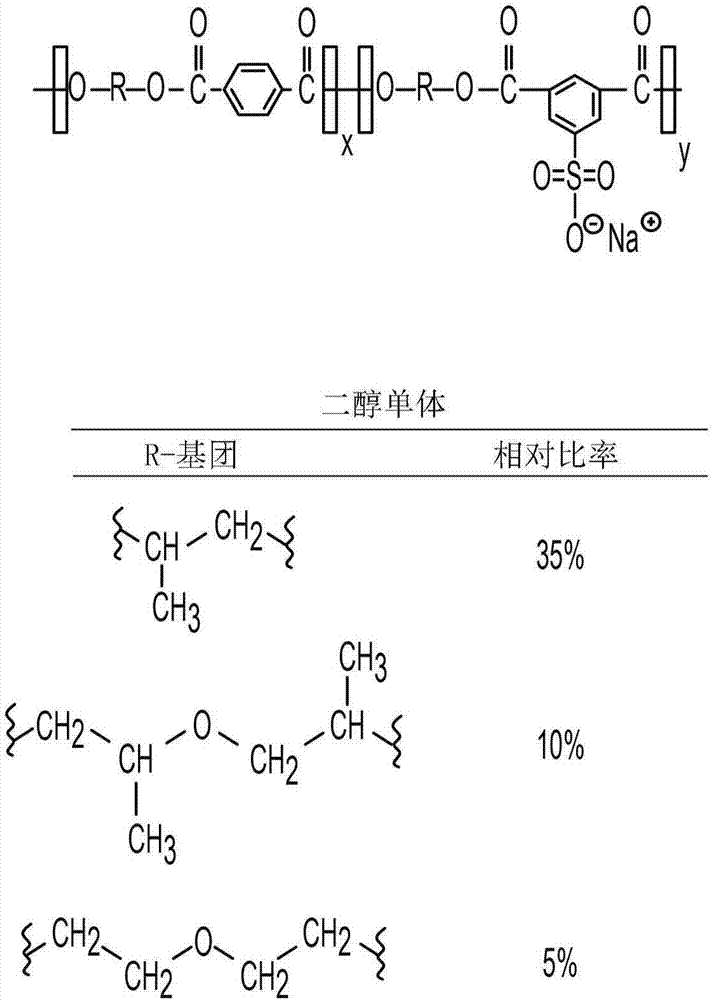

[0072] This example describes the preparation of a branched sodiosulfonated amorphous polyester (BSPE) according to an embodiment of the disclosure.

[0073] A branched amorphous sulfonated polyester resin was prepared as follows, comprising 0.425 molar equivalents of terephthalate, 0.080 molar equivalents of sodium 5-sulfoisophthalate, 0.4501 molar equivalents of 1,2-propanediol, and 0.050 molar equivalents of equivalent of diethylene glycol. In a one liter Parr reactor equipped with a heated bottom discharge valve, high viscosity twin turbine agitator and distillation receiver with cold water condenser, charged 388 grams of dimethyl terephthalate, 104.6 grams Sodium 5-sulfoisophthalate, 322.6 grams of 1,2-propanediol (1 molar excess of diol), 48.98 grams of diethylene glycol (1 molar excess of diol), trimethylolpropane (5 grams), and 0.8 grams of butyltin oxide hydroxide as catalyst. The reactor was heated with stirring to 165°C for 3 hours, and then heated again to 190°C ...

example 2

[0075] This comparative example shows the preparation of BSPE core particles without silver and without styrene shell.

[0076] Reactions were carried out in a 3 neck 500 mL round bottom flask equipped with overhead stirrer, reflux condenser, thermocouple, hot plate and nitrogen inlet (condenser served as nitrogen outlet). The flask was charged with 125 mL of deionized water (DIW) at room temperature (approximately 22°C). The DIW was heated to 90°C with stirring while running nitrogen through the solution (RPM = 330). Then 50.0 g of finely ground solid BSPE from Example 1 was added to the DIW (RPM=400). The solution was stirred at 90°C for 2 hours (RPM=400). A BSPE emulsion was obtained and cooled to room temperature with stirring (RPM=400). The final appearance of the BSPE emulsion is a white opaque solution.

example 3

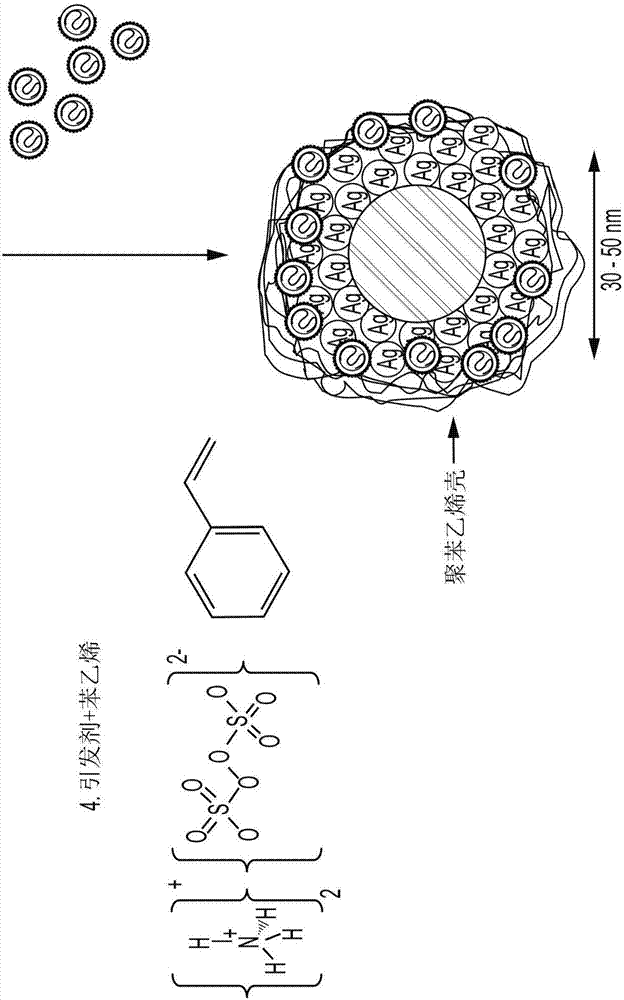

[0078] This comparative example shows the formation of a styrene shell around a BSPE core particle with no silver dispersed within the core particle.

[0079] Reactions were carried out in a 3 neck 500 mL round bottom flask equipped with overhead stirrer, reflux condenser, thermocouple, hot plate and nitrogen inlet (condenser served as nitrogen outlet). Approximately 240 mL of deionized water was charged to the flask at room temperature (22°C). Turn on the heat and set to 90°C and run nitrogen through the system for 30 minutes (RPM = 300). Once the temperature had stabilized, 50.0 g of finely ground BSPE from Example 1 was added to the flask (RPM = 300). The resulting solution was translucent with a blue tinge and was left to stir for 2 hours. The set point was then lowered to 75°C. Once the temperature had stabilized, 3.6 g of styrene (9% of total monomer) was added followed by dropwise addition of a solution of ammonium persulfate (0.08 g of ammonium persulfate dissolved ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com