Artificial blood vessel based on porcine small intestinal submucosa and preparation method of artificial blood vessel

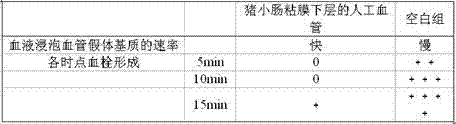

A technology of artificial blood vessels and submucosa, applied in coatings, medical science, prostheses, etc., can solve the problems of low long-term patency rate, slow blood flow, thrombosis, etc., and achieve excellent antithrombotic performance, good effect, Resistant to the effect of blood washout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 1.0g of freeze-dried SIS sample, grind it into powder with a grinder, transfer it to a test tube, add magnetron and 90mL of purified water, stir and mix evenly, add 500mg of trypsin, and stir the reaction at 50 degrees After 5 hours of enzymatic hydrolysis, boil to inactivate the enzyme, and obtain the degradation solution.

[0025] At room temperature, add polyurethane particles into tetrahydrofuran, and stir at a speed of 100 rpm for 2 hours; place the polyurethane solution in an environment with a vacuum of 0.3Mpa for defoaming; after standing for 3 hours, take out the polyurethane solution and squeeze it. The polyurethane solution produced is pretreated by a coagulation bath, and then the filamentary polyurethane is pulled out from the traction device, and then the filamentary polyurethane is wound on the rotating cylindrical mold; the cylindrical mold wound with the filamentary polyurethane Soak in absolute ethanol for 36 hours for coagulation bath qualitativ...

Embodiment 2

[0029] Weigh 1.0g of freeze-dried SIS sample, grind it into powder with a grinder, transfer it to a test tube, add magnetron and 95mL of purified water, stir and mix evenly, add 400mg of trypsin, and stir at 37 degrees to react After 24 hours, after the end of enzymatic hydrolysis, boil to inactivate the enzyme to obtain the degradation solution.

[0030]At room temperature, add polyurethane particles into tetrahydrofuran, and stir at a speed of 100 rpm for 2 hours; place the polyurethane solution in an environment with a vacuum of 0.3Mpa for defoaming; after standing for 3 hours, take out the polyurethane solution and squeeze it. The polyurethane solution produced is pretreated by a coagulation bath, and then the filamentary polyurethane is pulled out from the traction device, and then the filamentary polyurethane is wound on the rotating cylindrical mold; the cylindrical mold wound with the filamentary polyurethane Soak in absolute ethanol for 36 hours for coagulation bath q...

Embodiment 3

[0034] Weigh 1.0g of freeze-dried SIS sample, grind it into powder with a grinder, transfer it to a test tube, add magnetron and 90mL of purified water, stir and mix evenly, add 600mg of trypsin, and stir the reaction at 40 degrees After 12 hours of enzymatic hydrolysis, boil to inactivate the enzyme and obtain the degradation solution.

[0035] At room temperature, add polyurethane particles into tetrahydrofuran, and stir at a speed of 100 rpm for 2 hours; place the polyurethane solution in an environment with a vacuum of 0.3Mpa for defoaming; after standing for 3 hours, take out the polyurethane solution and squeeze it. The polyurethane solution produced is pretreated by a coagulation bath, and then the filamentary polyurethane is pulled out from the traction device, and then the filamentary polyurethane is wound on the rotating cylindrical mold; the cylindrical mold wound with the filamentary polyurethane Soak in absolute ethanol for 36 hours for coagulation bath qualitativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com