Preparation method of composite nano-fiber nerve scaffold

A technology of composite nanofibers and nerves, applied in the field of biomedical materials and nerve tissue engineering, can solve the problems of charge instability, electric stimulation intensity and duration difficult to control, etc., achieve time-saving process, promote nerve regeneration and structural reconstruction , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

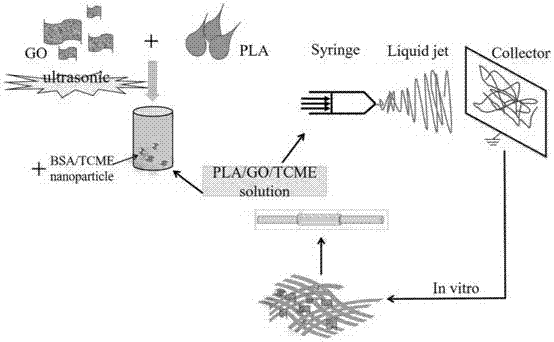

Method used

Image

Examples

Embodiment 1

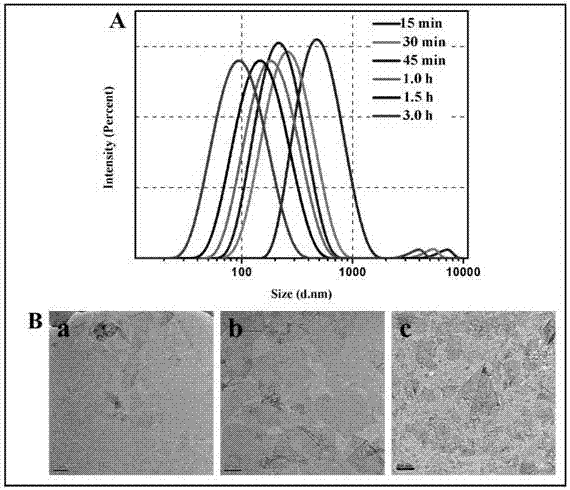

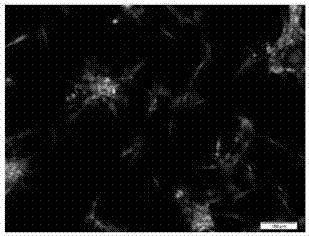

[0028] Example 1: Take 1.0 g of natural graphite powder and 0.5 g of sodium nitrate in a three-necked flask, slowly add 23 ml of concentrated sulfuric acid in an ice bath, and continue stirring for 15 min. Then slowly add 5g of potassium permanganate and keep the system temperature not exceeding 20°C, and continue to stir for 2h. The ice bath was removed and the system was heated to 35 °C, stirring was continued for 1.5 h. Add 46ml of deionized water slowly, maintain the system temperature at 98°C, and stir vigorously for 30min. Then cool in air, add 140ml deionized water and 10ml hydrogen peroxide to stop the reaction, the suspension turns bright yellow. Wash by centrifugation for 10 min, fully wash with 5% HCl and deionized water until the pH is close to neutral, and freeze-dry to obtain brown solid graphite oxide. Disperse the obtained solid into deionized water (1mg / ml), and ultrasonically exfoliate it with a power of 50W for 10min to obtain graphene oxide nanosheets, ce...

Embodiment 2

[0029]Example 2: Take 1.0 g of natural graphite powder and 0.5 g of sodium nitrate in a three-necked flask, slowly add 23 ml of concentrated sulfuric acid in an ice bath, and continue stirring for 15 min. Then slowly add 5g of potassium permanganate and keep the system temperature not exceeding 20°C, and continue to stir for 2h. The ice bath was removed and the system was heated to 35 °C, stirring was continued for 1.5 h. Add 46ml of deionized water slowly, maintain the system temperature at 98°C, and stir vigorously for 30min. Then cool in air, add 140ml deionized water and 10ml hydrogen peroxide to stop the reaction, the suspension turns bright yellow. Wash by centrifugation for 20 min, fully wash with 5% HCl and deionized water until the pH is close to neutral, and freeze-dry to obtain brown solid graphite oxide. Disperse the obtained solid into deionized water (1mg / ml), and ultrasonically exfoliate it with 100W power for 20min to obtain graphene oxide nanosheets, centrif...

Embodiment 3

[0030] Example 3: Take 1.0 g of natural graphite powder and 0.5 g of sodium nitrate in a three-necked flask, slowly add 23 ml of concentrated sulfuric acid in an ice bath, and continue stirring for 15 min. Then slowly add 5g of potassium permanganate and keep the system temperature not exceeding 20°C, and continue to stir for 2h. The ice bath was removed and the system was heated to 35 °C, stirring was continued for 1.5 h. Add 46ml of deionized water slowly, maintain the system temperature at 98°C, and stir vigorously for 30min. Then cool in air, add 140ml deionized water and 10ml hydrogen peroxide to stop the reaction, the suspension turns bright yellow. Wash by centrifugation, fully wash with 5% HCl and deionized water until the pH is close to neutral, and freeze-dry to obtain brown solid graphite oxide. Disperse the obtained solid into deionized water (1mg / ml), and ultrasonically exfoliate it with 180W power for 90min to obtain graphene oxide nanosheets, centrifuge for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com