Waterborne polyurethane coating material capable of preventing neutron radiation and preparation method of waterborne polyurethane coating material

A water-based polyurethane and anti-neutron radiation technology, applied in the field of coatings, can solve the problems of large consumables, difficult processing and construction, and high cost, and achieve the effects of excellent mechanical properties, excellent adhesive properties, and excellent anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

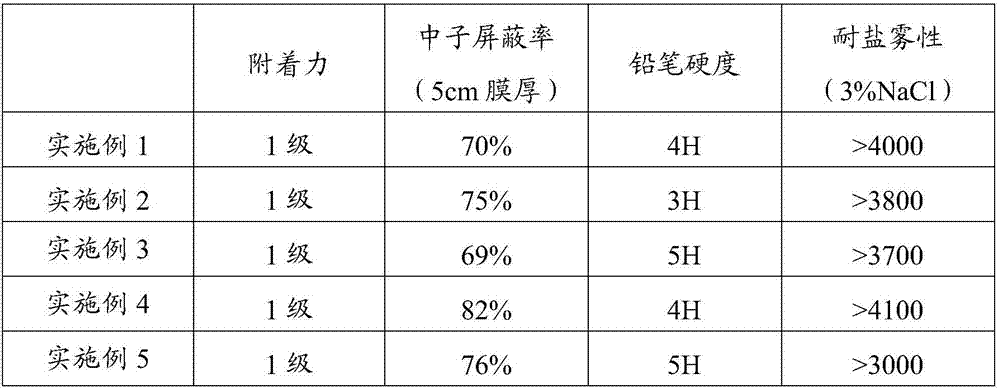

Examples

Embodiment 1

[0031] The present embodiment provides a kind of anti-neutron radiation water-based polyurethane coating, comprising the following components by weight: 40 parts of water-based polyurethane emulsion, 5 parts of graphene, 15 parts of lanthanum oxide, 15 parts of boron carbide, 8 parts of nano-alumina emulsion , 1.5 parts of sodium polyacrylate, 1.5 parts of polypropylene polyoxyethylene glyceryl ether, 1.5 parts of polyether siloxane copolymer, 1.5 parts of polyether modified silicone, 1.0 parts of water-based bentonite-thickening rheological agent, xanthan gum 2.5 copies;

[0032] The preparation method of described aqueous polyurethane emulsion, comprises the following steps:

[0033] (1) 80g phthalic anhydride polyester diol and 75g toluene diisocyanate and 15g organic fluorine modified graphene monomer were reacted at 90-100°C for 3 hours;

[0034] (2) Add 35g of 1,6-cyclohexanedimethanol, 15g of dimethylolpropionic acid, 35g of acetone and 0.3g of organic Bi salt catalyst...

Embodiment 2

[0044] The present embodiment provides a kind of anti-neutron radiation water-based polyurethane coating, comprising the following components by weight: 30 parts of water-based polyurethane emulsion, 10 parts of graphene, 10 parts of lanthanum oxide, 20 parts of boron carbide, 5 parts of nano-alumina emulsion , 2 parts of sodium polyacrylate, 1 part of polypropylene polyoxyethylene glyceryl ether, 2 parts of polyether siloxane copolymer, 1 part of polyether modified silicone, 2 parts of water-based bentonite-thickening rheological agent, xanthan gum 2 copies;

[0045] The preparation method of described aqueous polyurethane emulsion, comprises the following steps:

[0046] (1) 60g polycarbonate diol and 120g isophorone diisocyanate and 5g organic fluorine modified graphene monomer were reacted at 90-100°C for 4 hours;

[0047] (2) Add 20g of 1,6-hexanediol, 20g of dimethylolpropionic acid, 20g of acetone and 0.5g of stannous octoate, and react at 60-80°C for 3 hours;

[0048...

Embodiment 3

[0057] The present embodiment provides a kind of anti-neutron radiation water-based polyurethane coating, comprising the following components by weight: 50 parts of water-based polyurethane emulsion, 3 parts of graphene, 20 parts of lanthanum oxide, 10 parts of boron carbide, 10 parts of nano-alumina emulsion , 1 part of sodium polyacrylate, 2 parts of polypropylene polyoxyethylene glyceryl ether, 1 part of polyether siloxane copolymer, 2 parts of polyether modified silicone, 0.5 parts of water-based bentonite-thickening rheological agent, xanthan gum 3 copies;

[0058] The preparation method of described aqueous polyurethane emulsion, comprises the following steps:

[0059] (1) 90g of polycaprolactone diol and 30g of 1,6-hexamethylene diisocyanate and 25g of organic fluorine-modified graphene monomer were reacted at 90-100°C for 2 hours;

[0060] (2) Add 50g of isosorbide, 8g of dimethylolpropionic acid, 50g of acetone and 0.1g of n-butyltin dilaurate, and react at 60-80°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com