N-acetyl-D-glucosamine capsule preparation and preparation method thereof

A technology of glucosamine and acetyl, which is applied in the field of N-acetyl-D-glucosamine capsule preparations and its preparation, can solve problems such as poor fluidity, low particle bulk density, and easy discoloration, and achieve improved compliance, simple process, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

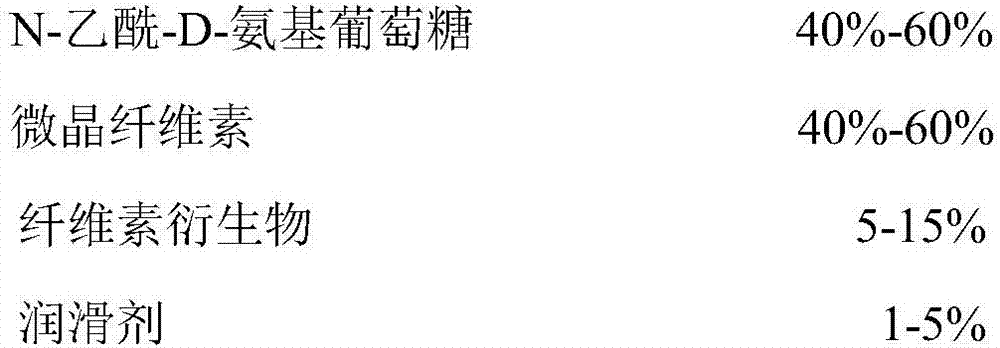

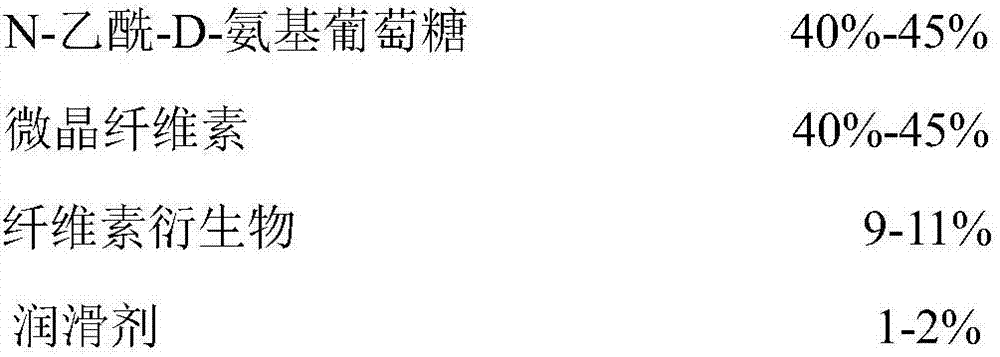

[0033] Embodiment 1: the selection of auxiliary material

[0034] The main drug is N-acetyl-D-glucosamine, and the auxiliary materials are selected from diluents, binders, disintegrants, lubricants such as starch, carboxymethyl starch, pregelatinized starch, hydroxypropyl methylcellulose, low Substitute hydroxypropyl cellulose, microcrystalline cellulose, magnesium stearate, micronized silica gel, etc. According to the present invention, the auxiliary materials can also be various combinations of the above ingredients.

[0035] Mix the main ingredient: excipients at a ratio of 1:1, and then place them under conditions of strong light (4500±500lx), high temperature (60°C) or high humidity (25°C, relative humidity of 90±5%) for 10 Take a sample after 1 day, and check the changes of content and related substances before and after placing by HPLC method, and observe the changes of drug conditions such as appearance color, weight loss on drying, etc. at the same time. The test re...

Embodiment 2

[0040] Embodiment 2: the research of preparation technology

[0041] The raw material of this product, N-acetyl-D-glucosamine, is a needle-like crystal with poor fluidity and compressibility, so the raw material needs to be crushed. Two pulverizers were used to carry out the pulverization test, and the results are shown in Table 2. Bulk density measurement method: Weigh the weight (g) of the material filled with a 100ml measuring cylinder, and the value obtained is the bulk density value, which needs to be weighed to an accuracy of 0.1g.

[0042] Table 2 shows the bulk density under different crushing methods

[0043]

[0044] The test results show that the pulverization effect by ball mill is the most ideal, not only the bulk density is high, but also the granules are uniform after granulation, the dispersibility is good, and it is easy to put into No. 2 capsules, which improves the patient's compliance. However, after the turbine crushing, the particles are uneve...

Embodiment 3

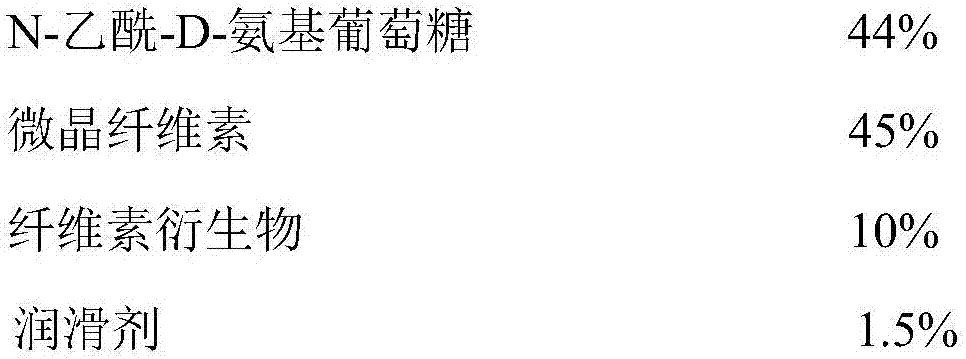

[0046] Take 1.5kg of N-acetyl-D-glucosamine crystals and grind them by ball milling. After 16 minutes of grinding, raw material particles with a bulk density of 69g / 100mL are obtained and sieved.

[0047] Weigh 1.188kg of crushed and sieved qualified N-acetyl-D-glucosamine, 0.959kg of microcrystalline cellulose, and 115g of low-substituted hydroxypropyl cellulose according to the prescription quantity, put them into the mixer and mix for 15 minutes, take them out, and use dry The French granulator performs dry granulation, the main pressure is 1.7Mpa, the side pressure is 0.55Mpa, the feeding current is 1A, and the rotating speed of the roller is 300 rpm. After sizing with a 14-mesh nylon sieve, sieve and weigh the granules. Add 1% micropowder silica gel therein by particle weight, mix for 15 minutes, take out, fill in No. 2 capsules, and adjust the punch to make the particle weight suitable, and suck off the fine powder on the surface of the capsule. After passing the inspec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com