Method for preparing magnetic adsorbent by using waste zinc manganese batteries and biomass

A magnetic adsorbent, zinc-manganese battery technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc. Large surface area and other problems, to achieve the effect of high value-added resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1. Take the electrode material of the waste zinc-manganese battery, grind the battery electrode material into powder and pass it through a sieve to obtain electrode powder with a particle size of less than 125 μm;

[0046] Step 2, with sulfur powder and ferrous sulfate as the mixed energy substrate, the mixed volume ratio is 1:1:1 Thiobacillus thiooxidans bacteria liquid, Leptospira ferrous oxide bacteria liquid and Thiobacillus ferrooxidans bacteria The mixture was mixed to form a mixed leaching strain, and the mixed leaching strain was regularly inoculated and cultivated for 5 days in a shaker with a rotation speed of 150r / min and a temperature of 35°C with a mixed energy substrate and nutrient salts, and then centrifuged, After filtering, the biological extract is obtained;

[0047] During the inoculation process:

[0048] The solvent of nutrient salt is water, and the solute of nutrient salt is: (NH 4 ) 2 SO 4 , KH with a content of 1.0g / L 2 PO 4 , MgSO w...

Embodiment 2

[0056] Step 1. Take the electrode material of the waste zinc-manganese battery, grind the battery electrode material into powder and pass it through a sieve to obtain electrode powder with a particle size of less than 125 μm;

[0057] Step 2, with sulfur powder and ferrous sulfate as the mixed energy substrate, the mixed volume ratio is 1:1:1 Thiobacillus thiooxidans bacteria liquid, Leptospira ferrous oxide bacteria liquid and Thiobacillus ferrooxidans bacteria The mixture was mixed to form a mixed leaching strain, and the mixed leaching strain was regularly inoculated and cultivated for 3 days in a shaker with a rotation speed of 160r / min and a temperature of 40°C with mixed energy substrates and nutrient salts, and then centrifuged, After filtering, the biological extract is obtained;

[0058] During the inoculation process:

[0059] The solvent of nutrient salt is water, and the solute of nutrient salt is: (NH 4 ) 2 SO 4 , KH with a content of 1.0g / L 2 PO 4 , MgSO wi...

Embodiment 3

[0067] Step 1. Take the electrode material of the waste zinc-manganese battery, grind the battery electrode material into powder and pass it through a sieve to obtain electrode powder with a particle size of less than 125 μm;

[0068] Step 2, with sulfur powder and ferrous sulfate as the mixed energy substrate, the mixed volume ratio is 1:1:1 Thiobacillus thiooxidans bacteria liquid, Leptospira ferrous oxide bacteria liquid and Thiobacillus ferrooxidans bacteria The mixture was mixed to form a mixed leaching strain, and the mixed leaching strain was regularly inoculated and cultivated for 5 days in a shaker with a rotation speed of 130r / min and a temperature of 30°C with mixed energy substrates and nutrient salts, and then centrifuged, After filtering, the biological extract is obtained;

[0069] During the inoculation process:

[0070] The solvent of nutrient salt is water, and the solute of nutrient salt is: (NH 4 ) 2 SO 4 , KH with a content of 1.0g / L 2 PO 4 , MgSO wi...

PUM

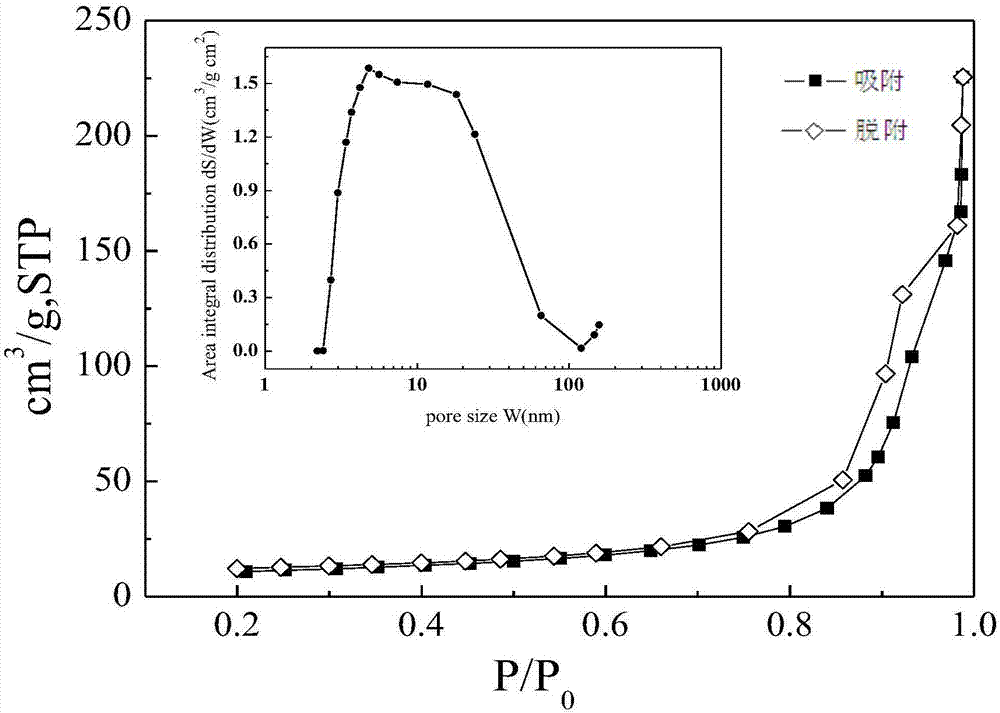

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com