A kind of graphene composite metal foam and preparation method thereof

A technology of graphene composite and metal foam, applied in the direction of non-metallic elements, chemical instruments and methods, carbon compounds, etc., can solve the problems of high cost, low production efficiency, unsuitable for industrial production, etc., and achieve good dispersion performance and stable dispersion good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Using T700SC 24K (24,000 monofilaments) polyacrylonitrile-based carbon fiber tows as raw materials, trim the tip surfaces of the above 78 carbon fiber tows, and place them vertically above the electrolytic cell filled with a 0.5M ammonium carbonate aqueous solution. As an anode, it is connected to the positive pole of the DC power supply; then an area of 100cm 2 The SS 304 stainless steel net is fully immersed in the ammonium carbonate aqueous solution, and is connected as the cathode to the negative pole of the DC power supply; carefully adjust the parallel distance between the neat tip surface of the carbon fiber tow and the liquid surface of the solution before powering on, so as to just touch the liquid surface As the standard, the error of allowing the tip surface to enter the solution is no more than 5mm relative to the liquid surface; then turn on the DC power supply, control the constant voltage 32V, and start working. Climbing, at this time, the carbon fiber ...

Embodiment 2

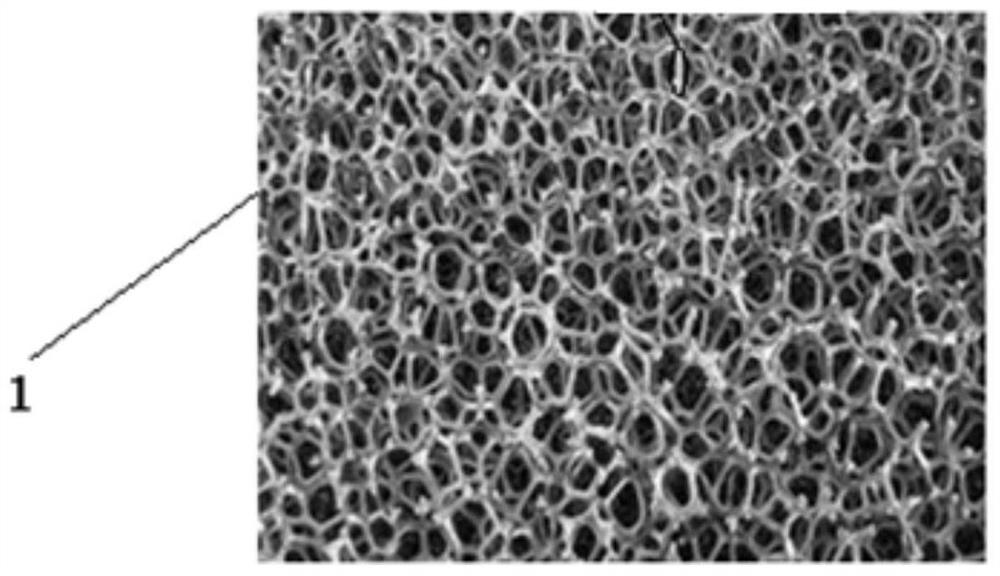

[0065] It is basically the same as Example 1, the main difference is: the dispersion of the composite nanomaterial composed of graphene oxide quantum dots and graphene obtained in the above way is diluted to a concentration of 0.2mg / mL, and a porosity of 98%, pore diameter An open-cell foamed copper alloy plate (length 2cm, width 2cm, thickness 1cm) with an average of 0.25mm is placed in an open stainless steel container (inner cavity size: length 2.2cm, width 2.2cm, thickness 1.5cm), and then the above Pour the dispersion liquid into the container so that the foamed copper alloy plate is completely submerged, put it into a vacuum drying oven, vacuumize and heat to 60°C for drying treatment, and after all the water is completely evaporated, an oxide layer formed on the surface of the foamed copper alloy plate A graphene layer composed of graphene quantum dots and graphene layers (its thickness is 1 μm, and the plane conductivity is 2000S cm -1 , the plane thermal conductivity ...

Embodiment 3

[0067] Using 0.1mm thick graphite paper as raw material, place it vertically above the electrolytic cell filled with 0.1M sodium sulfate aqueous solution, and connect it as an anode to the positive pole of the DC power supply; 2 The nickel sheet is fully immersed in the sodium sulfate aqueous solution, and is connected as the cathode to the negative electrode of the DC power supply; carefully adjust the parallel distance between one end surface of the graphite paper and the liquid surface of the solution before powering on, so that it just touches the liquid surface, allowing The error of the end surface entering the solution is no more than 5mm relative to the liquid surface; then turn on the DC power supply, control the constant voltage of 40V, and start working. It is also possible to adjust the end surface of the graphite paper to work within the range of no more than 5mm above the liquid surface. At this time, the working current density fluctuation range of the relative e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com