Method for enriching rhenium from copper smelting waste acid

A technology of copper smelting and waste acid, applied in the direction of improving process efficiency, etc., can solve the problems of large reagent consumption, poor extraction selectivity, secondary environmental pollution, etc., achieve effective separation and efficient recovery, mild desorption conditions, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

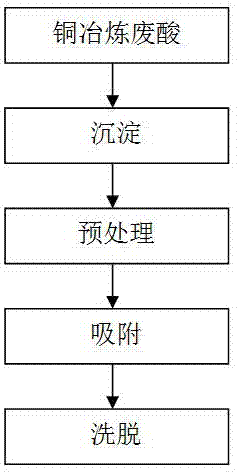

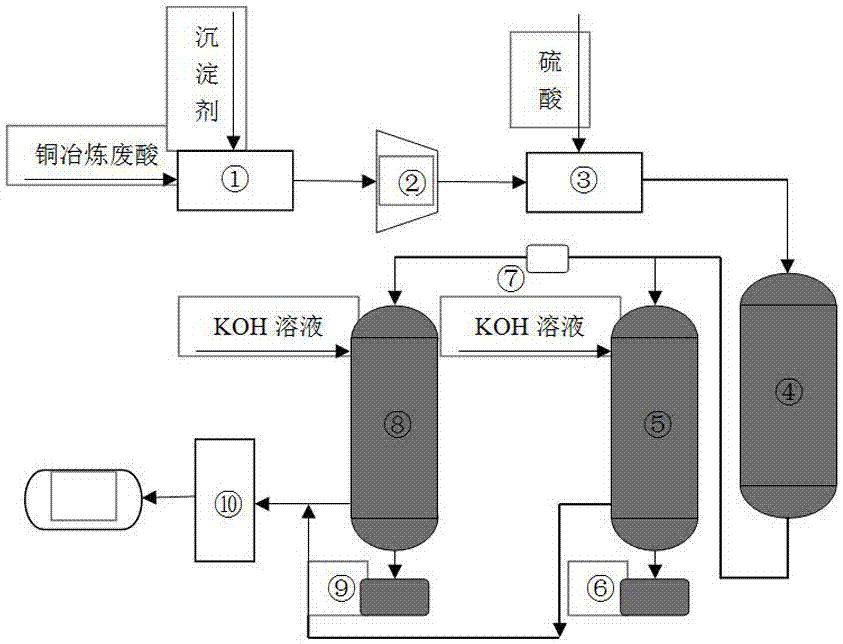

Method used

Image

Examples

Embodiment 1

[0027] Using the copper smelting waste acid provided by a certain company A as raw material, the inductively coupled plasma emission spectrometer was used to detect that the copper smelting waste acid contained 1260 mg / L of copper, 394 mg / L of arsenic, 604 mg / L of iron, and Rhenium 65 mg / L, containing 79440 mg / L sulfuric acid.

[0028] Add calcium hydroxide and calcium oxide to the sedimentation tank equipped with waste acid from copper smelting in a weight ratio of 4 to 6:1 until the pH of the solution is 8, press filter to separate, and collect the filtrate in the liquid storage tank (pH adjustment tank), pass sulfuric acid into the liquid storage tank to adjust the pH of the filtrate to 5, and pass the rhenium-containing filtrate through the biochar adsorption tower for pretreatment. When the concentration of each interfering ion is less than 5 mg / L, pass the rhenium-containing solution through the copper-loaded biological The carbon adsorption tower absorbs and enriches rh...

Embodiment 2

[0030] Using copper smelting waste acid provided by a company B as raw material, using inductively coupled plasma emission spectrometer to detect, the copper smelting waste acid contained 952 mg / L of copper, 586 mg / L of arsenic, 814 mg / L of iron, and Rhenium 76 mg / L, containing 56870 mg / L sulfuric acid.

[0031] Add calcium hydroxide and calcium oxide to the sedimentation tank equipped with waste acid from copper smelting in a weight ratio of 4 to 6:1 until the pH of the solution is 12, press filter to separate, and collect the filtrate in the liquid storage tank (pH adjustment tank), pass sulfuric acid into the liquid storage tank to adjust the pH of the filtrate to 6, and pass the rhenium-containing filtrate through the biochar adsorption tower for pretreatment, when the concentration of each interfering ion is less than 5 mg / L, pass the rhenium-containing solution through the copper-loaded biochar The adsorption tower absorbs and enriches rhenium, and when the adsorption re...

Embodiment 3

[0033] Using copper smelting waste acid provided by a certain company C as raw material, the inductively coupled plasma emission spectrometer was used to detect that the copper smelting waste acid contained 1380 mg / L of copper, 471 mg / L of arsenic, 985 mg / L of iron, and Rhenium 49 mg / L, containing 58640 mg / L sulfuric acid.

[0034] In the sedimentation tank equipped with waste acid from copper smelting, add a precipitant mixed with calcium hydroxide and calcium oxide in a weight ratio of 4-6:1 until the pH of the solution is 10, separate by pressure filtration, and collect the filtrate in the liquid storage tank (pH adjustment tank), pass sulfuric acid into the storage tank to adjust the pH of the filtrate to 7, and pass the rhenium-containing filtrate through the biochar adsorption tower for pretreatment, when the concentration of each interfering ion is less than 5 mg / L, pass the rhenium-containing solution through the copper-loaded biochar The adsorption tower absorbs and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com