A kind of composite fiber negative electrode material and preparation method thereof

A technology of composite fiber and negative electrode material, applied in the direction of negative electrode, fiber chemical characteristics, battery electrode, etc., can solve the problems of reducing energy density of energy storage device, interface mismatch capacity attenuation, binder instability, etc., to improve the structure Stability, improve cycle stability, improve the effect of high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 2g of ferric nitrate and 3.75g of tetrabutyl titanate in 5g of N,N dimethylformamide, stirring continuously until completely dissolved to form A solution; then dissolve 4g of polyacrylonitrile with a molecular weight of 150,000 in 28g Form B solution in N,N dimethylformamide; slowly drop A solution into B solution, and stir until the mixture is uniform.

[0029] (2) Prepare the precursor fiber by using the general electrospinning method from the mixed solution, the feeding speed is 0.5ml / h, the voltage is 22kV, the humidity is controlled at 40%, the temperature is kept at 25°C, the distance between the nozzle and the receiver It is 15cm.

[0030] (3) The precursor fiber sample was clamped and fixed by two graphite plates, and calcined in nitrogen at 750°C for 3 hours to obtain the iron titanate / titanium dioxide / activated carbon composite fiber negative electrode material.

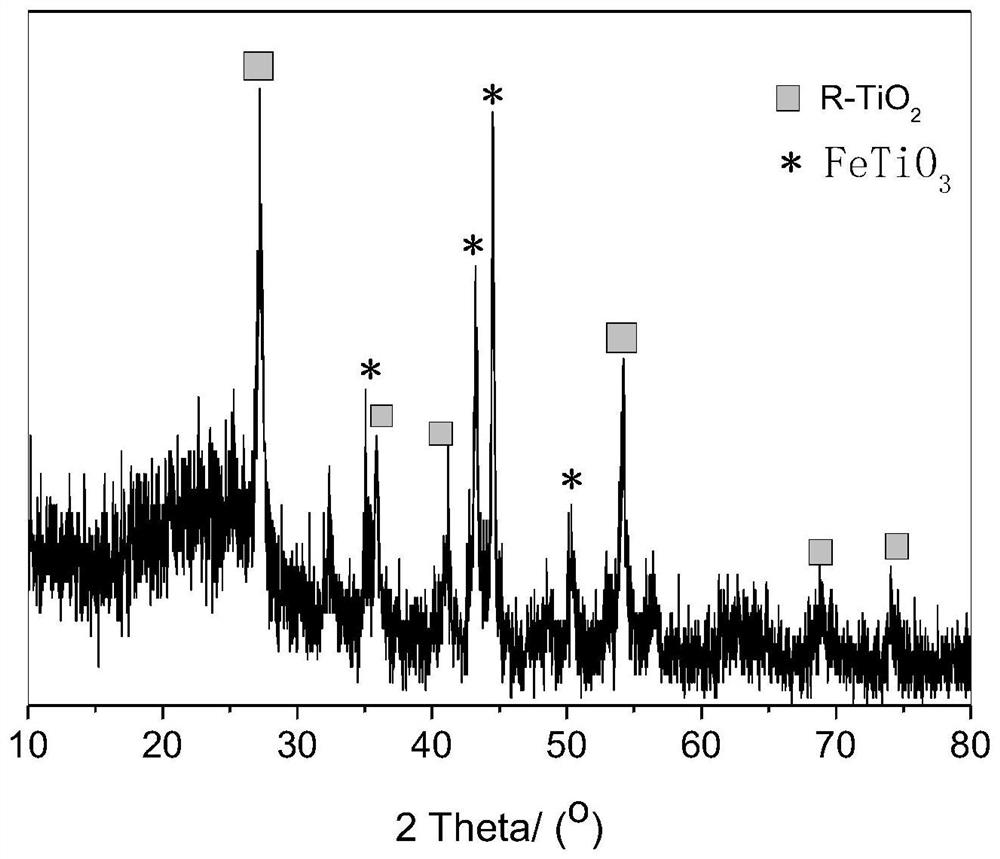

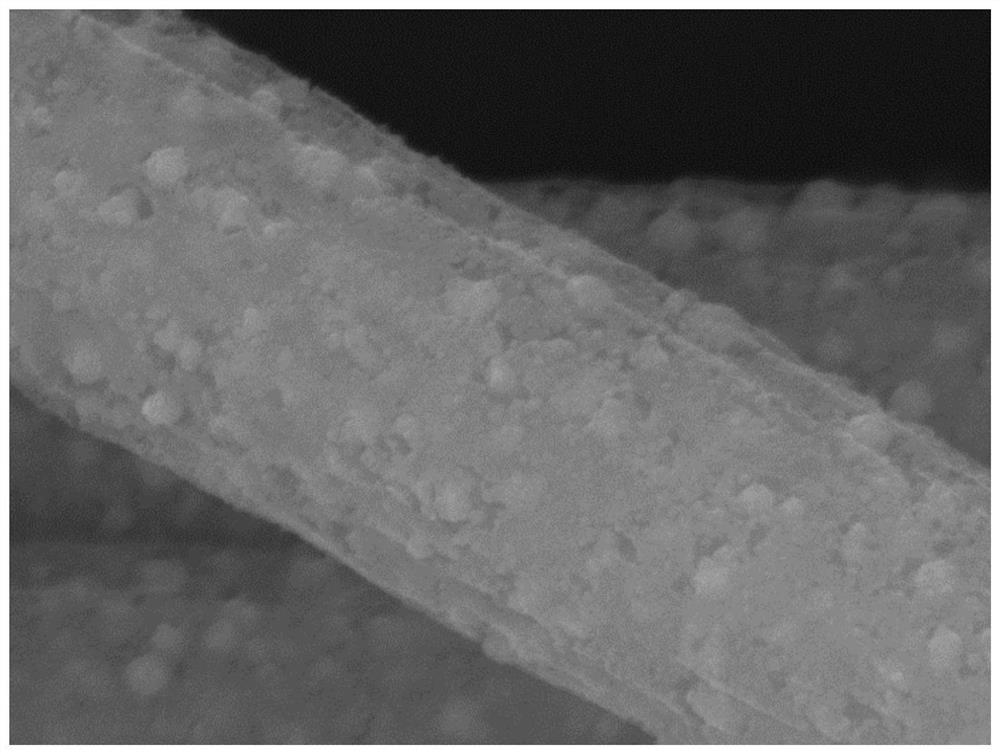

[0031] Depend on figure 1 XRD and figure 2 SEM results show that the prepared co...

Embodiment 2

[0033] (1) Dissolve 1g of ferric nitrate and 8.45g of tetrabutyl titanate in 10g of N,N dimethylacetamide, stirring continuously until completely dissolved to form A solution; then dissolve 10g of polyacrylonitrile with a molecular weight of 150,000 in 40g Form B solution in N,N dimethylacetamide; slowly drop A solution into B solution, and stir until the mixture is uniform.

[0034] (2) Prepare the precursor fiber by using the general electrospinning method from the mixed solution, the feeding speed is 0.5ml / h, the voltage is 22kV, the humidity is controlled at 40%, the temperature is kept at 25°C, the distance between the nozzle and the receiver 15cm;

[0035] (3) The precursor fiber was directly calcined at 700° C. for 5 hours in nitrogen to obtain the iron titanate / titanium dioxide / activated carbon composite fiber negative electrode material.

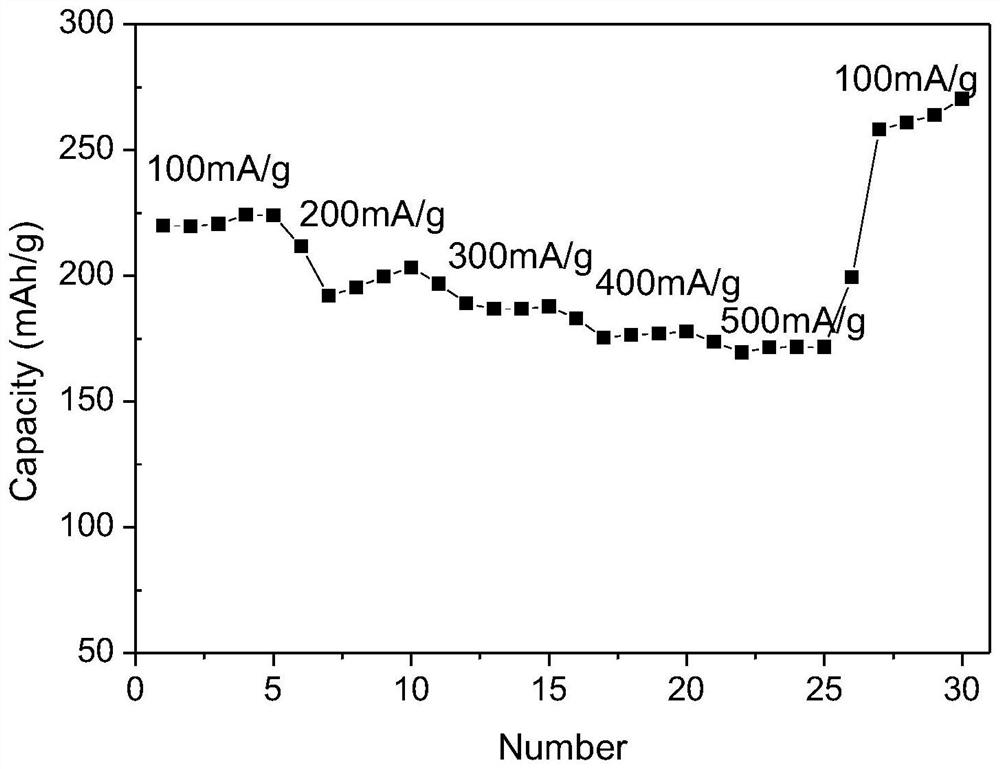

[0036] The prepared composite fiber negative electrode material is composed of iron titanate, titanium dioxide, and activated car...

Embodiment 3

[0038] (1) Dissolve 2g of ferric nitrate and 3.1g of tetrabutyl titanate in 5g of acetonitrile, stirring continuously until completely dissolved to form A solution; then 5g of polyacrylonitrile with a molecular weight of 150,000 is dissolved in 30g of acetonitrile to form B solution; Slowly add solution A to solution B dropwise and stir until evenly mixed.

[0039] (2) Prepare the precursor fiber by using the general electrospinning method from the mixed solution, the feeding speed is 0.5ml / h, the voltage is 22kV, the humidity is controlled at 40%, the temperature is kept at 25°C, the distance between the nozzle and the receiver 15cm;

[0040] (3) The precursor fiber was directly calcined at 750° C. for 1 hour in nitrogen to obtain the iron titanate / titanium dioxide / activated carbon composite fiber negative electrode material.

[0041] The prepared composite fiber negative electrode material is composed of iron titanate, titanium dioxide, and activated carbon three-phase comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com