Preparation method for high-temperature-resistance high-crystallized near-stoichiometric-ratio continuous SiC fiber

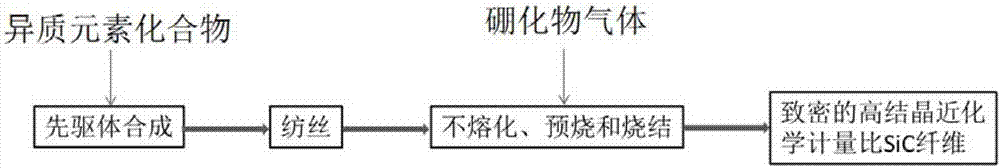

A near-stoichiometric, high-crystalline technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems that the preparation method cannot amplify the preparation cost, the continuous SiC fiber has small crystal grains, and has a loose structure, and achieves easy industrial production. The effect of reducing production costs and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Add 500g of polysilane and 5g of zirconium chloride (1%) into a three-necked flask, react at a cracking temperature of 500°C and a synthesis temperature of 460°C for 8 hours, cool naturally to normal temperature to become solid, and use 500mL xylene Dissolve, remove insolubles by filtration, place the filtrate in a three-necked flask, and distill under reduced pressure at 350°C for 1 hour to obtain 200g of zirconium-containing precursor polymer with a softening point of 196°C and a number average molecular weight of 2.72×10 3 g / mol, the molecular weight distribution coefficient is 3.65.

[0045] (2) Place the zirconium-containing precursor polymer in the melting drum of the melt spinning device, heat it up to 350°C under the protection of an inert atmosphere, and wait until it is completely melted to become a uniform melt, then heat it at 280°C and a pressure of 0.5MPa , Draw spinning at a speed of 410m / min to obtain fibrils with an average diameter of 14um and a co...

Embodiment 2

[0049] Place the fibrils obtained in steps (1) and (2) of Example 1 in an air non-melting treatment device for non-melting treatment, then raise the temperature to 450 ° C at a heating rate of 5 ° C / hour, and drop to room temperature after 18 hours of heat preservation , and put the fiber in another non-melting furnace, and replace it with nitrogen for three times, feed the mixed gas of borane and nitrogen, the volume ratio of borane is 50%, rise to 450°C at a heating rate of 50°C / hour and keep it For 0.5 hours, non-melting fibers were obtained with an oxygen content of 5%.

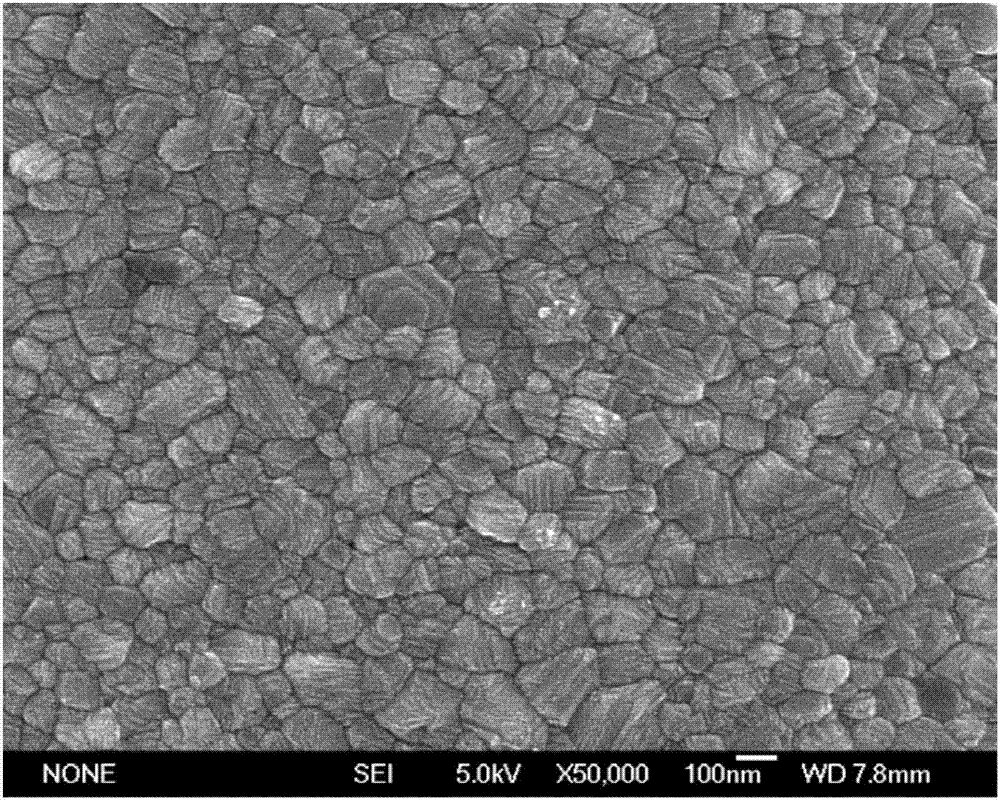

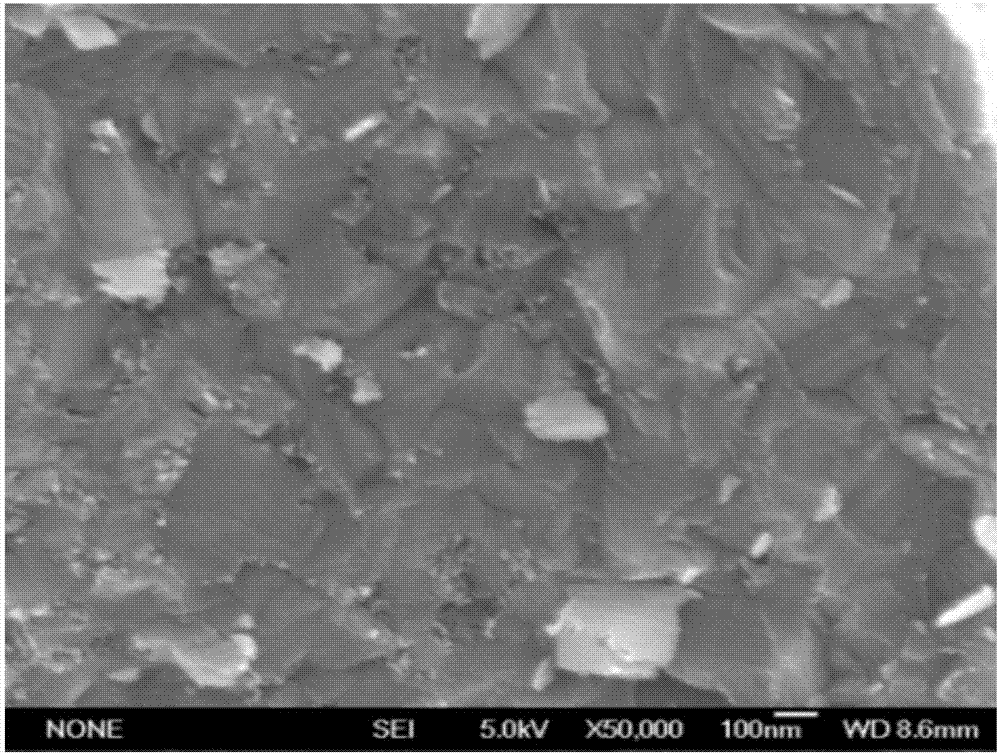

[0050] Put the non-melting fiber in the graphite furnace, pass in nitrogen for protection, raise the temperature to 1200°C at a rate of 50°C / hour, change the atmosphere to argon after holding for 1 hour, and then increase the temperature to 1200°C at a rate of 200°C / hour 1600°C, heat preservation for 1 hour, and Si-C-O-Zr fibers were prepared after cooling. The temperature of the tubular graphite furna...

Embodiment 3

[0053] (1) Dissolve 500g of polycarbosilane in 500mL of xylene, add it to the reactor, then add 50g of aluminum acetylacetonate (10%) into the reactor, react at 300°C for 10 hours, cool naturally to room temperature and become solid , dissolved with 800mL xylene, filtered to remove insoluble matter, put the filtrate in a three-necked flask, and distilled under reduced pressure at 360°C for 3 hours to obtain 512g of aluminum-containing precursor polymer with a softening point of 221°C and a number average molecular weight of 7.02 ×10 3 g / mol, and the molecular weight distribution coefficient is 2.38.

[0054](2) Put the aluminum-containing precursor polymer in the melting cylinder of the melt spinning device, heat it up to 372°C under the protection of an inert atmosphere, and wait until it is completely melted to form a uniform melt, then heat it at 348°C and a pressure of 0.3MPa , Draw spinning at a speed of 450m / min to obtain fibrils with an average diameter of 13um and a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com