Preparation of glucose sensor based on graphene and graphene oxide composite material

A glucose sensor and composite material technology, which is applied in the direction of analyzing materials, electrochemical variables of materials, and material analysis through electromagnetic means, can solve the problems of reduced electrode stability, increased preparation complexity, and increased preparation costs, etc., to achieve improved stability performance, rapid electrochemical determination, and the effect of improving electrode stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The concrete steps of this preparation method are as follows:

[0036] (1) Pretreatment of the glassy carbon electrode: first, the glassy carbon electrode Use A1 with particle size of 1.0μm, 0.3μm and 0.05μm in turn 2 o 3 The suspension was polished to a mirror surface on the suede, and finally ultrasonically cleaned with absolute ethanol and double distilled water respectively, and set aside;

[0037] (2) Preparation of modified glassy carbon electrode:

[0038] a) Transfer the film-like graphene prepared by CVD to the surface of the polished glassy carbon electrode by bubbling or etching, which can significantly improve the electrical conductivity of the electrode. The substrate for growing graphene can be copper or It can be a sheet of metal such as nickel or platinum. In order to achieve ideal conductivity, the transfer times of the graphene film can be 1 to 5 times, and 2 times are commonly used.

[0039] Alternatively, transfer the foamed graphene prepared b...

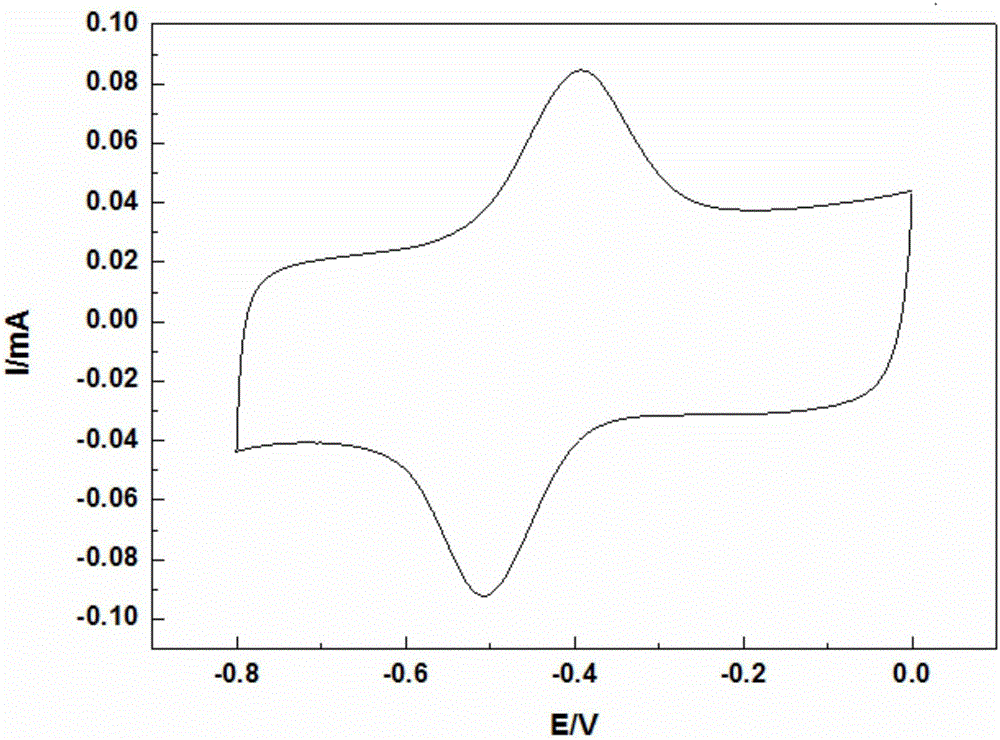

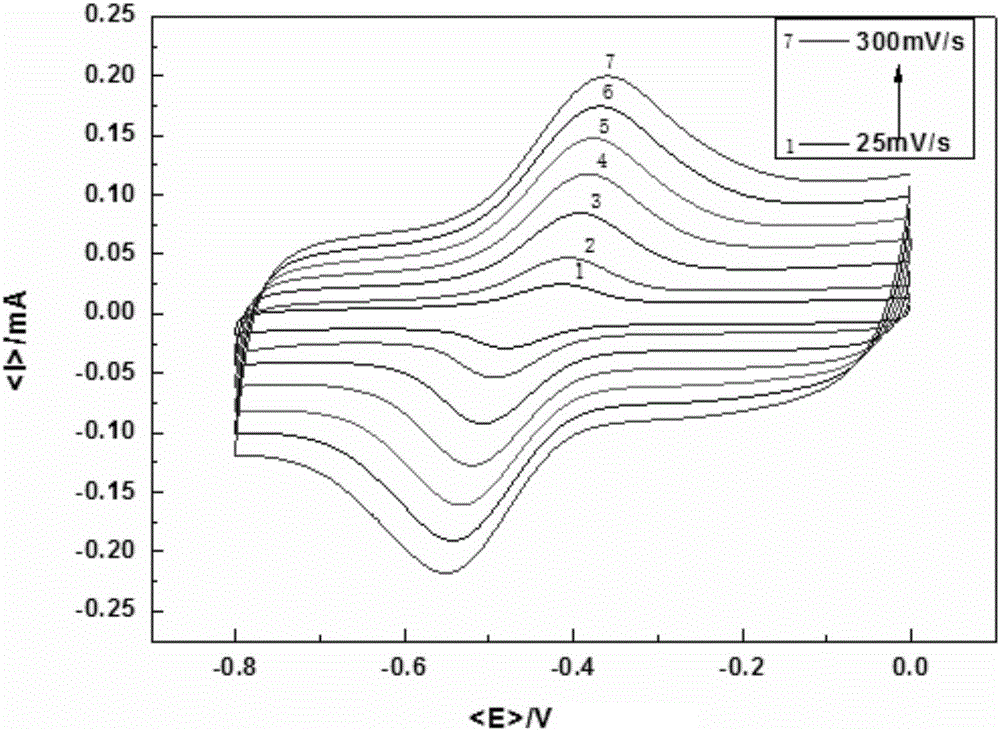

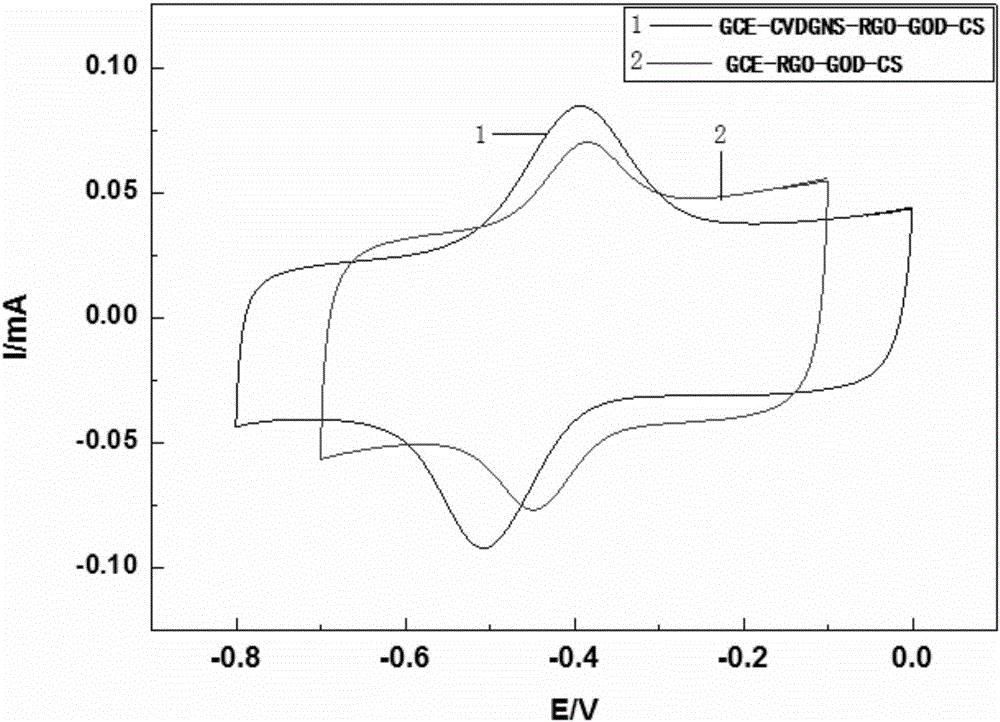

Embodiment 1

[0045] The single-layer graphene grown on the copper foil by CVD is transferred from the substrate copper foil by the bubbling method (see Chinese invention patent, publication number CN102719877A), and fixed on the surface-cleaned glassy carbon electrode superior. First prepare the chitosan acetic acid solution (concentration of acetic acid solution is 2wt%) that concentration is 10mg / ml respectively, concentration is the chitosan acetic acid solution of the graphene oxide of 1mg / ml, the glucose oxidase phosphoric acid that concentration is 10mg / ml Salt buffer solution (the concentration of phosphate buffer solution is 0.1mol / L). Then, the glassy carbon electrode whose surface is modified with CVD graphene was modified, and 10 μl of graphene oxide chitosan acetic acid solution was added dropwise on the electrode. After the electrode was dried at room temperature, 10 μl of glucose oxidase phosphate buffered saline solution was added dropwise. After the electrode was dried, t...

Embodiment 2

[0047] The single-layer graphene grown on copper foil by CVD method was transferred from the substrate copper foil by bubbling method, and fixed on a diameter of on the glassy carbon electrode. In order to obtain a better conductive effect, the above operation is repeated once, that is, double-layer graphene is modified on the surface of the glassy carbon electrode. Other treatment methods and electrochemical experiments are the same as in Example 1. The experimental results show that the redox peak position and the redox peak current on the obtained cyclic voltammetry curve are basically the same as those in Example 1. It is proved that modifying a layer of graphene on the working electrode can obtain the ideal conductivity enhancement effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com