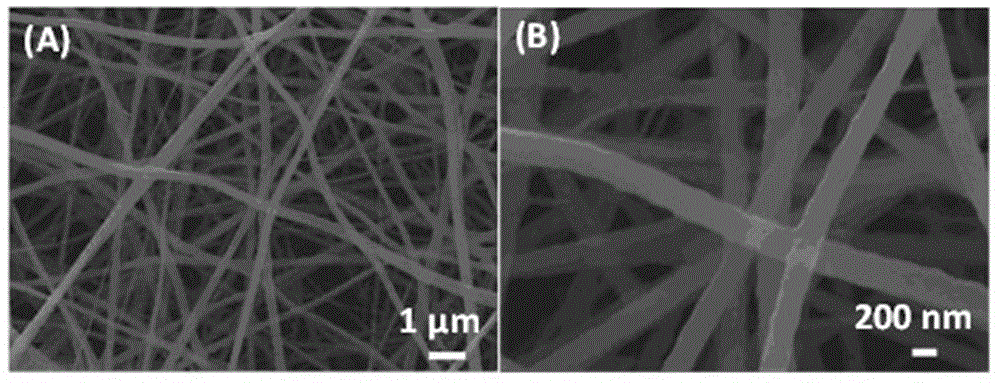

Preparation method of high-nickel ternary NCM622-nanowire material

A nanowire, high-nickel technology, applied in the field of nanomaterials and electrochemistry, to achieve high discharge specific capacity, high yield, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

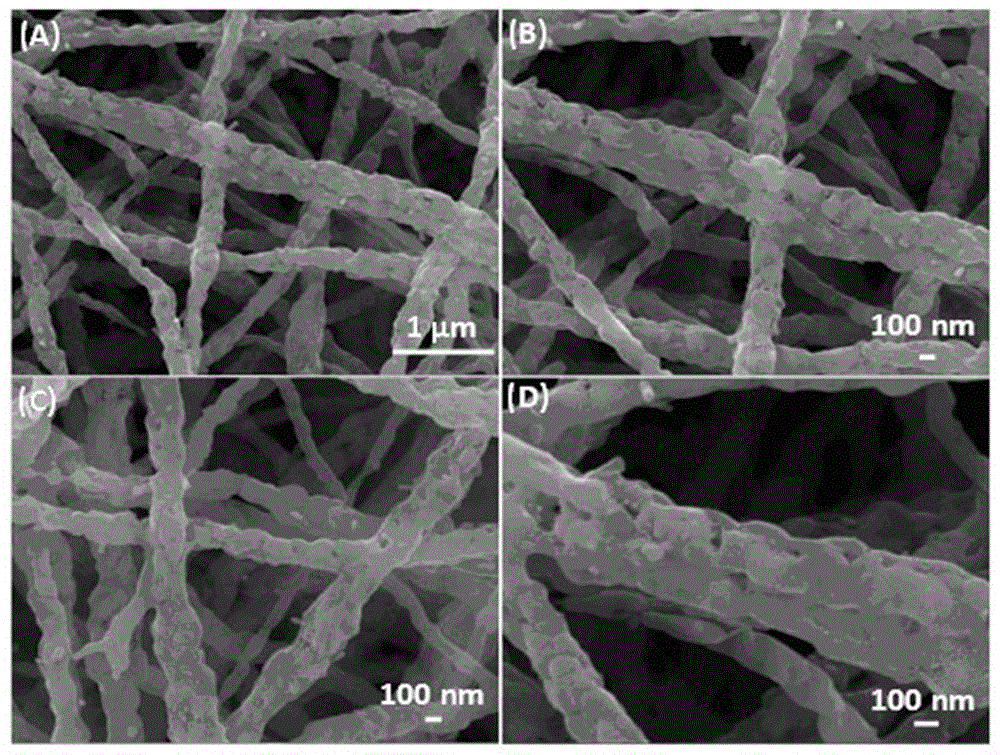

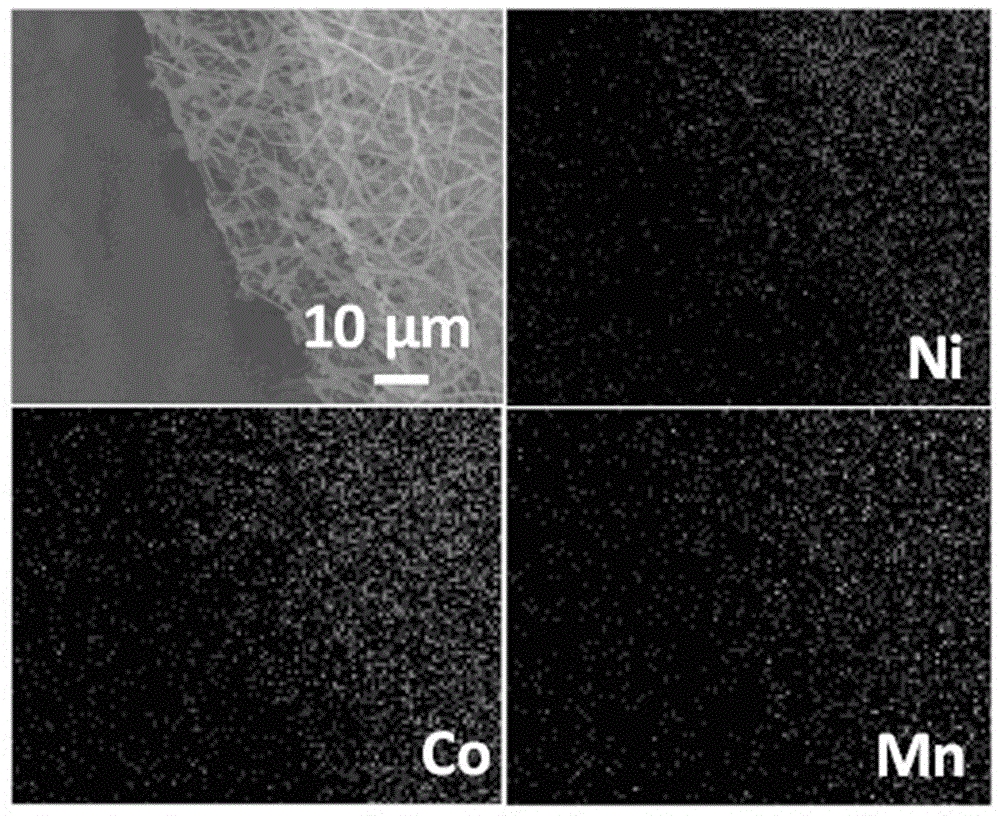

[0035] The preparation method of high-nickel ternary NCM622-nanometer wire material comprises the steps:

[0036] 1) Add 10.5 mmol of lithium acetate, 6 mmol of nickel acetate, 2 mmol of cobalt acetate and 2 mmol of manganese acetate into 40.0 mL of absolute ethanol, stir magnetically at 40 °C for 1 h to dissolve them all, and form a uniform and transparent solution;

[0037] 2) Weigh 3.8 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the solution obtained in step 1), and stir magnetically for 8 h to dissolve it completely;

[0038] 3) Weigh 0.5 g of glucose and add it to the solution obtained in step 2), and stir magnetically for 1 h to dissolve it completely;

[0039] 4) The solution obtained in step 3) was dissolved in 0.3 ml h -1 The speed is transferred to the syringe, electrospinning is carried out under the conditions of positive high voltage 14.5 kV and negative high voltage 1.5 kV, and aluminum foil is used to receive nanofibers;

[0040] 5) ...

Embodiment 2

[0048] The preparation method of high-nickel ternary NCM622-nanometer wire material, it comprises the steps:

[0049] 1) Add 10.7 mmol of lithium acetate, 6 mmol of nickel acetate, 2 mmol of cobalt acetate and 2 mmol of manganese acetate into 40.0 mL of absolute ethanol, stir magnetically at 40 °C for 1 h to dissolve them all, and form a uniform and transparent solution;

[0050] 2) Weigh 4.0 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the solution obtained in step 1), and stir magnetically for 11 h to dissolve it completely;

[0051] 3) Weigh 0.4 g of fructose and add it to the solution obtained in step 2), and stir magnetically for 0.5 h to dissolve it completely;

[0052] 4) The solution obtained in step 3) was dissolved in 0.3 ml h -1 The speed is transferred to the syringe, electrospinning is carried out under the conditions of positive high voltage 15.0 kV and negative high voltage 2.5 kV, and aluminum foil is used to receive nanofibers;

[0...

Embodiment 3

[0057] 1) Add 10.2 mmol of lithium acetate, 6 mmol of nickel acetate, 2 mmol of cobalt acetate and 2 mmol of manganese acetate into 40.0 mL of absolute ethanol, stir magnetically at 40 °C for 2 h to dissolve them all, and form a uniform and transparent solution;

[0058] 2) Weigh 3.9 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the solution obtained in step 1), and stir magnetically for 12 h to dissolve it completely;

[0059] 3) Weigh 0.8 g of glucose and add it to the solution obtained in step 2), and stir magnetically for 1 h to dissolve it completely;

[0060] 4) The solution obtained in step 3) was dissolved in 0.3 ml h -1 The speed is transferred to the syringe, electrospinning is carried out under the conditions of positive high voltage 15.0 kV and negative high voltage 2.5 kV, and aluminum foil is used to receive nanofibers;

[0061] 5) The product obtained in step 4) was placed in a muffle furnace for pre-sintering, and the temperature was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com