Sodium alginate/dissimilar metal MOFs hollow nanocage hybrid membrane as well as preparation and application

A sodium alginate and heterometallic technology, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, membrane technology, etc., can solve problems affecting membrane stability, poor interface interaction, easy to form defects, etc., and achieve good operation The effects of stability, high selectivity, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1. Preparation of sodium alginate / heterometallic MOFs hollow nanocage hybrid membrane, the steps are as follows:

[0018] Step 1. Preparation of a heterometallic MOFs hollow nanocage: Dissolve 1.2g iron acetylacetonate, 0.928g zinc nitrate hexahydrate and 0.192g terephthalic acid in a mixed solution of 512mL N,N-dimethylformamide and ethanol 4g of polyvinylpyrrolidone was added to it, and after magnetic stirring at room temperature for 10min, the reddish-brown solution was transferred to a hydrothermal kettle and reacted at 100°C for 3h to obtain an orange-red precipitate; the orange-red precipitate Sequentially wash with N,N-dimethylformamide and ethanol and dry in a vacuum oven at 40°C for 12 hours to obtain an orange powdery solid, which is a hollow nanocage of heterometallic MOFs, specifically, the radial size of the particle is about 150nm , Fe with a pore size of about 6.4 nm III -HMOF-5.

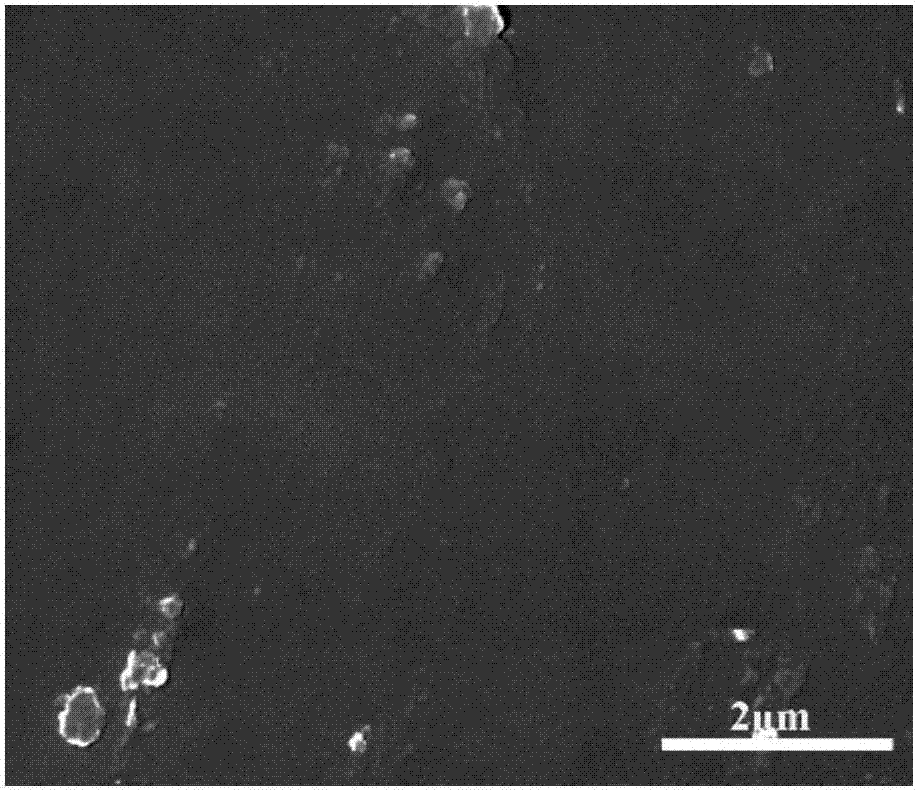

[0019] Step 2, film formation: Weigh 0.0102g of heterometallic M...

Embodiment 2

[0021] Example 2, preparation of sodium alginate / heterometallic MOFs hollow nanocage hybrid membrane, the steps are as follows:

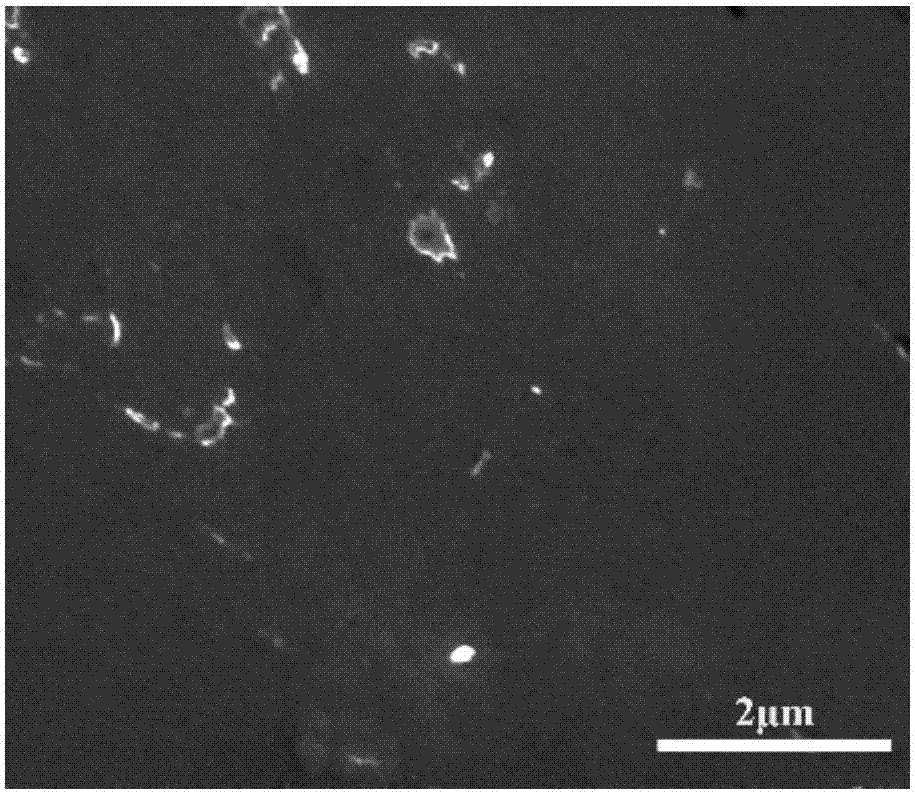

[0022] The preparation process is basically the same as in Example 1, except that in step 2, the amount of heterometallic MOFs hollow nanocages dissolved in 25 mL of deionized water is changed from 0.0102 g to 0.0306 g; finally sodium alginate / heterometallic MOFs hollow nanocage hybrid membrane (membrane 2), the surface electron microscope image of membrane 2 is as follows figure 2 shown.

[0023] Membrane 2 is used for pervaporation ethanol dehydration, and the permeation flux is 1540g / m under the conditions of 76°C and raw material concentration of 90 / 10wt% (ethanol / water) 2 h, the separation factor is 3423, such as Figure 5 shown.

Embodiment 3

[0024] Example 3, preparation of sodium alginate / heterometallic MOFs hollow nanocage hybrid membrane, the steps are as follows:

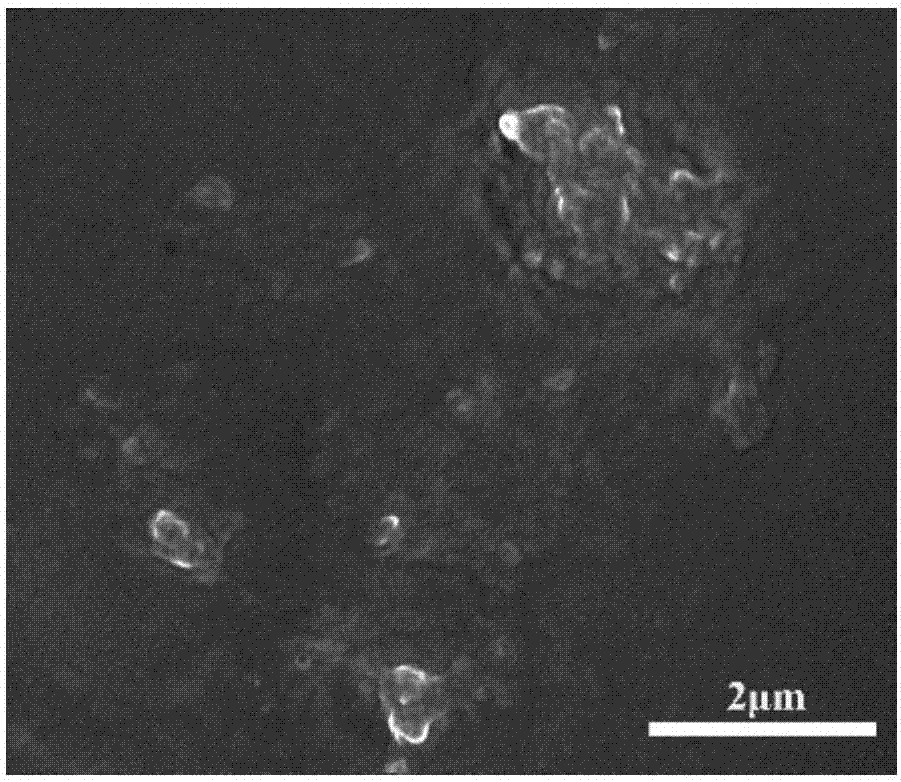

[0025] The preparation process is basically the same as in Example 1, except that in step 2, the amount of heterometallic MOFs hollow nanocages dissolved in 25 mL of deionized water is changed from 0.0102 g to 0.051 g; finally sodium alginate / heterometallic MOFs hollow nanocage hybrid membrane (membrane 3), the surface electron microscope image of membrane 3 is shown in image 3 shown.

[0026] Membrane 3 is used for pervaporation ethanol dehydration, and the permeation flux is 1380g / m under the conditions of 76°C and raw material concentration of 90 / 10wt% (ethanol / water) 2 h, the separation factor is 2215, such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com