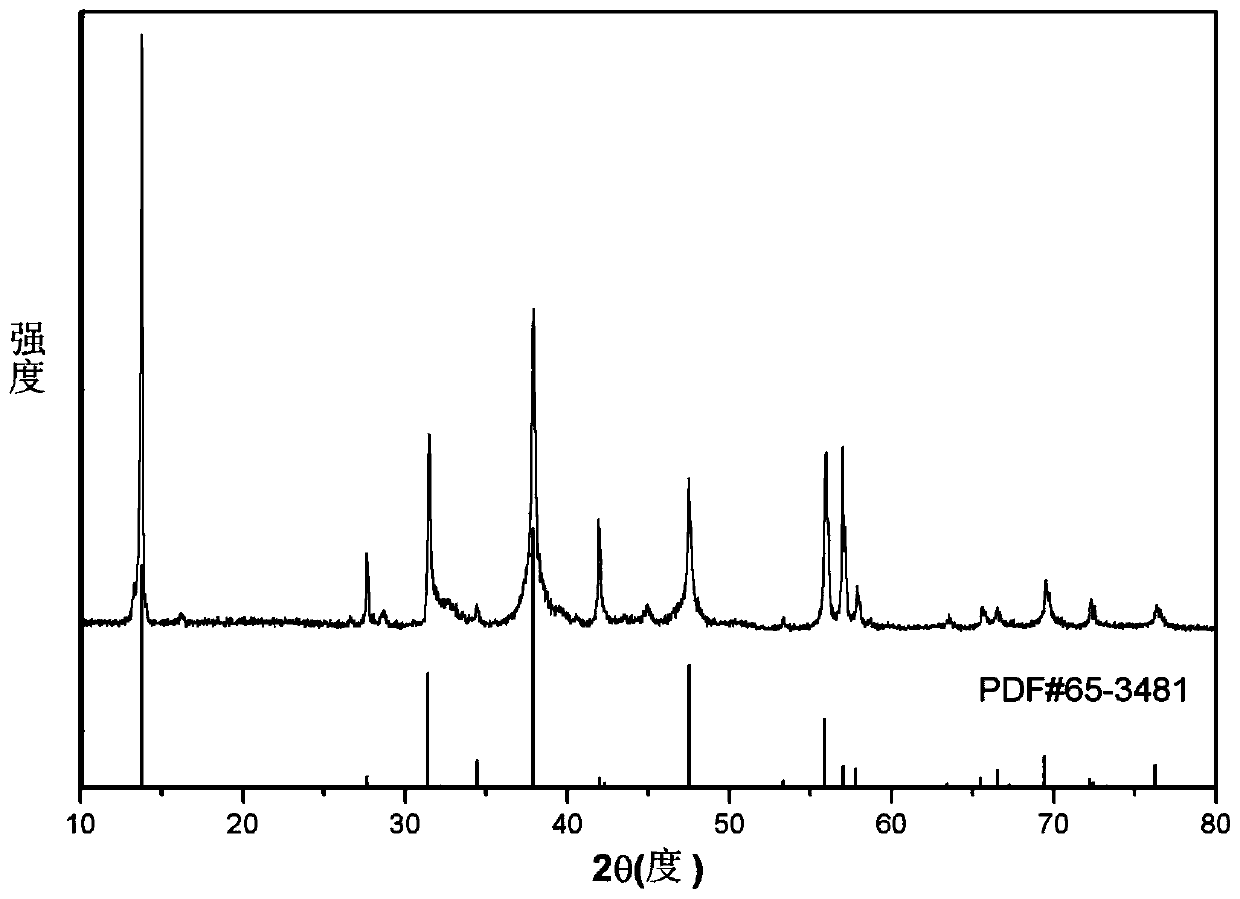

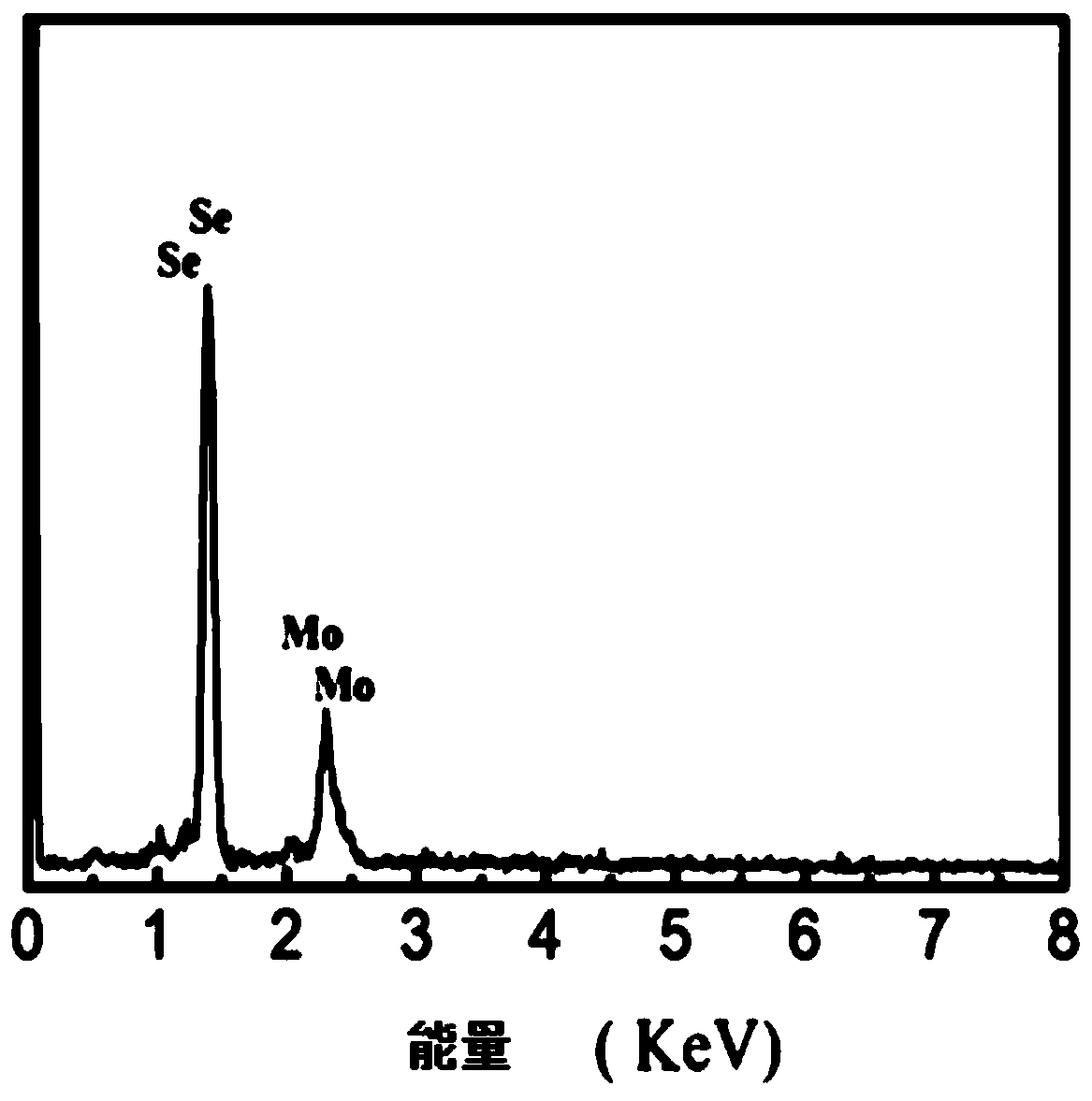

A six -square -sized selenium -shaped microcargo powder material and its preparation method

A molybdenum diselenide, powder material technology, applied in binary selenium/tellurium compounds, nanotechnology and other directions, can solve problems such as environmental defects, and achieve the effects of simple preparation method, uniform shape and lower reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, use elemental molybdenum powder and elemental selenium powder as raw materials, and the molar ratio of elemental molybdenum powder and elemental selenium powder is 1:2.5 and pour it into a ball mill jar, add 15mL absolute ethanol in the jar, then add steel balls in the jar, steel The total mass ratio of the ball mass to the raw material is 20:1, the rotational speed of the ball mill is set at 200 rpm, and the ball mill is performed for 10 hours. After the ball mill stops, open the ball mill tank, add co-solvent to the slurry, the mass ratio of co-solvent to the total mass of raw materials is 1:1, co-solvent includes NaCl and KCl, the molar ratio of NaCl and KCl is 1:1, and then add 8mL Anhydrous ethanol, set the speed of the ball mill to 100 rpm, and ball mill again for 30 minutes. The ball-milled slurry was poured into a beaker, and put into a drying oven for drying. The temperature of the drying oven was set at 60° C., and the drying time was 18 hours. The dri...

Embodiment 2

[0033] First, use elemental molybdenum powder and elemental selenium powder as raw materials, the molar ratio of elemental molybdenum powder and elemental selenium powder is 1:3 and pour into the ball mill jar, add 15mL absolute ethanol in the jar, add steel ball again in the jar, steel The total mass ratio of the ball mass to the raw material is 25:1, the rotational speed of the ball mill is set at 225 rpm, and the ball mill is 13 hours. After the ball mill stops, open the ball mill tank, add co-solvent to the slurry, the mass ratio of co-solvent to the total mass of raw materials is 1:1.5, co-solvent includes NaCl and KCl, the molar ratio of NaCl and KCl is 1:1, and then add 8mL Anhydrous ethanol, set the speed of the ball mill to 125 rpm, and ball mill again for 45 minutes. The ball-milled slurry was poured into a beaker, and put into a drying oven for drying. The temperature of the drying oven was set at 70° C., and the drying time was 21 hours. The dried material was pou...

Embodiment 3

[0035] First, use elemental molybdenum powder and elemental selenium powder as raw materials, and the molar ratio of elemental molybdenum powder and elemental selenium powder is 1:3.5 and pour it into the ball mill jar, add 15mL absolute ethanol in the jar, then add steel balls in the jar, steel The total mass ratio of the ball mass to the raw material is 30:1, the rotational speed of the ball mill is set at 250 rpm, and the ball mill is performed for 15 hours. After the ball mill stops, open the ball mill tank, add co-solvent to the slurry, the mass ratio of co-solvent to the total mass of raw materials is 1:2, co-solvent includes NaCl and KCl, the molar ratio of NaCl and KCl is 1:1, and then add 8mL Anhydrous ethanol, the speed of the ball mill was set to 150 rpm, and ball milled again for 60 minutes. The ball-milled slurry was poured into a beaker, and put into a drying oven for drying. The temperature of the drying oven was set at 80° C., and the drying time was 24 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com